Method for improving enzyme production and secondary metabolites of fungi

A technology of secondary metabolites and secondary metabolites, which is applied in the fields of microbiology, medicine and chemical industry, can solve problems such as unsatisfactory effects, and achieve the effects of improving impact, increasing efficiency, and increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

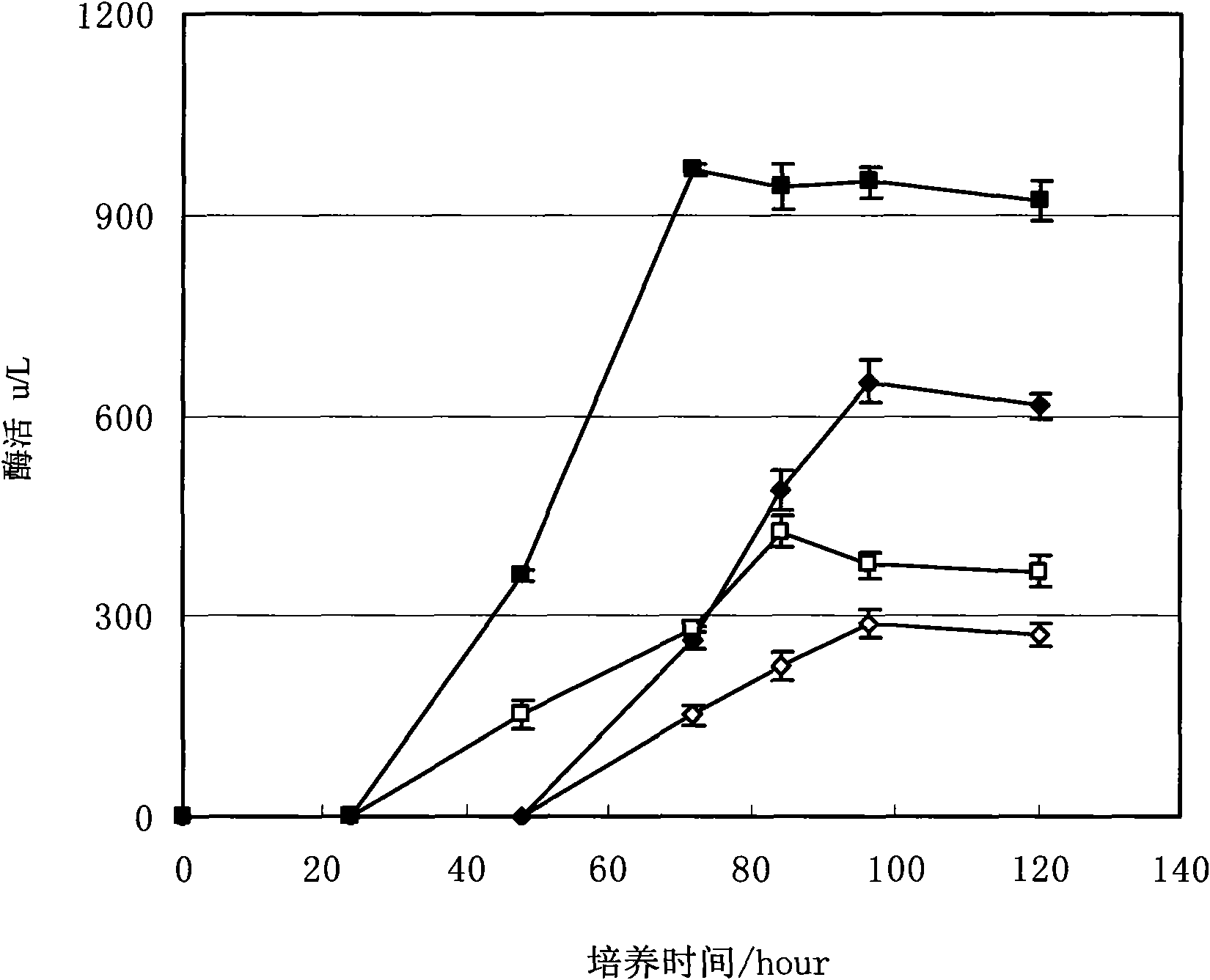

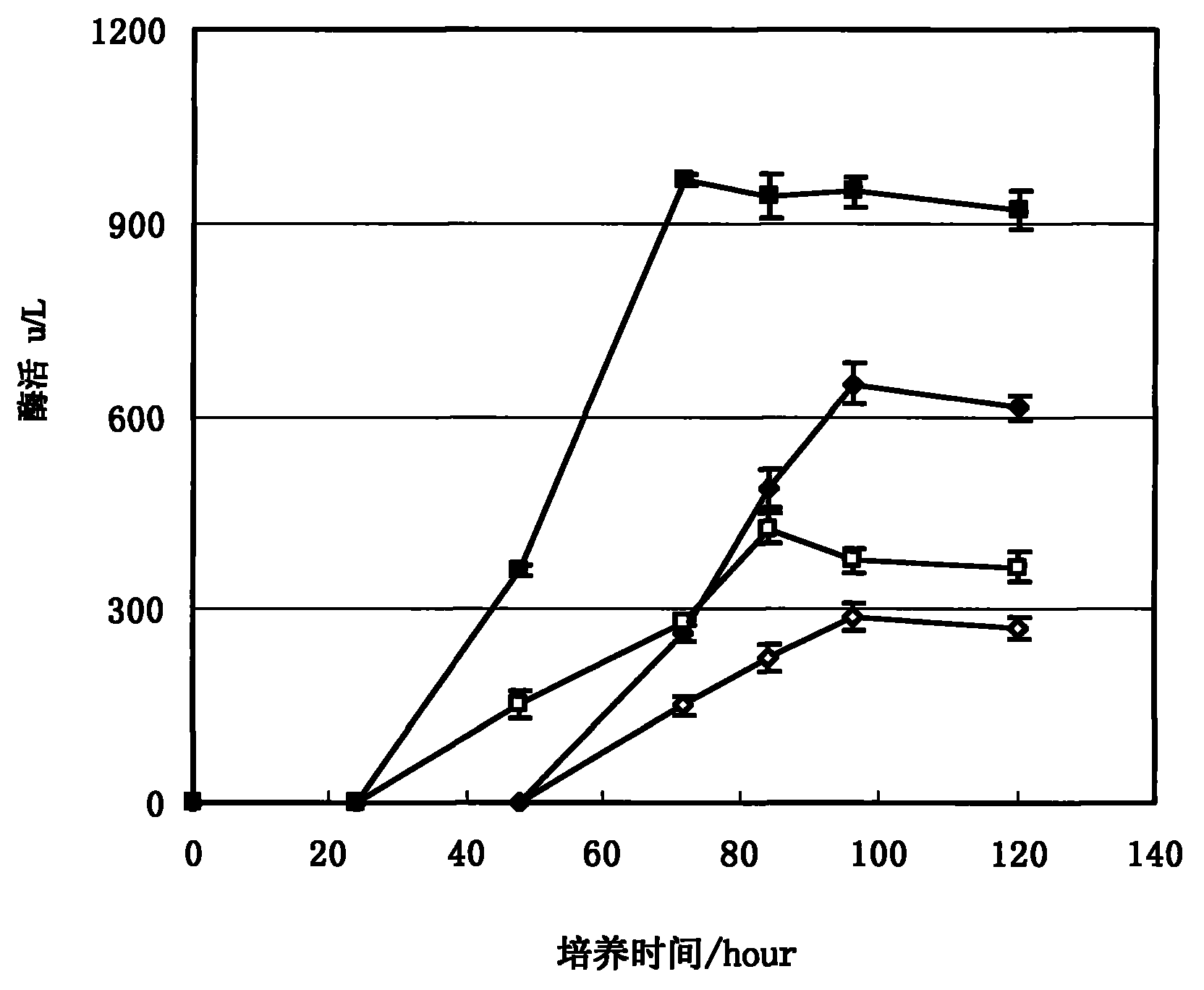

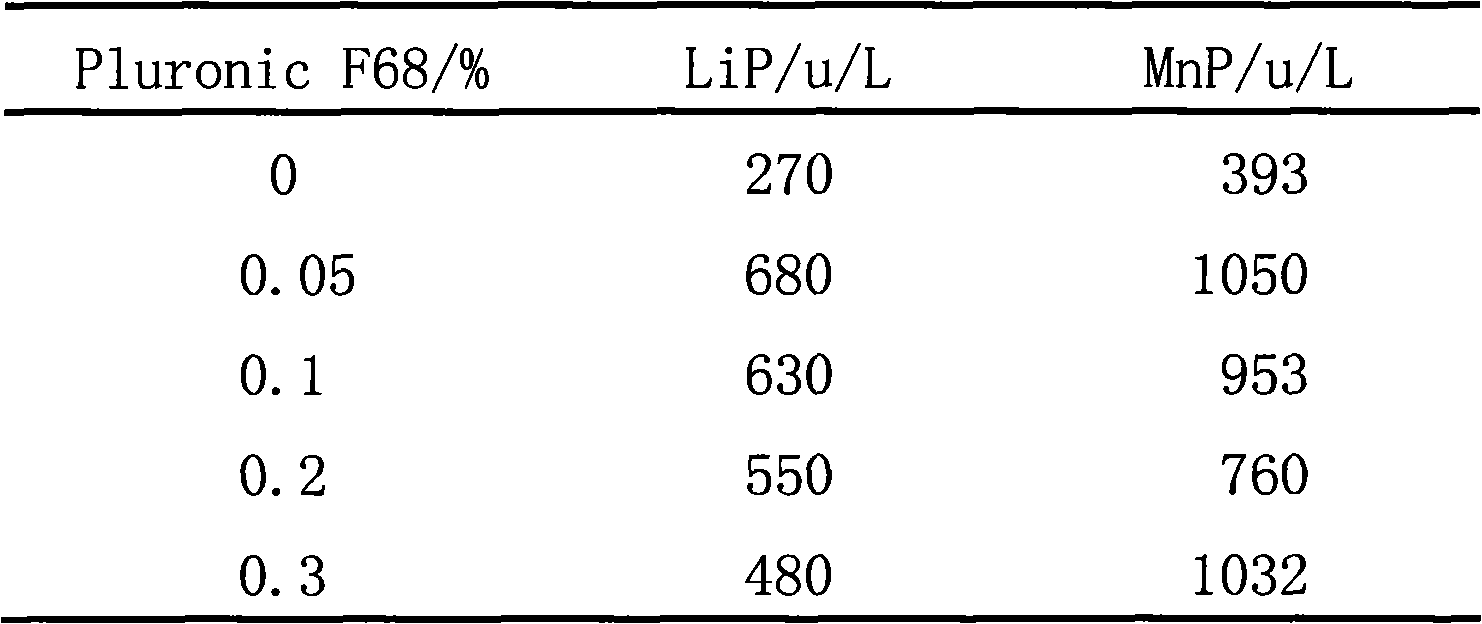

[0028] The production of embodiment 1 lignin hydrolase

[0029] (1) Trametes versicolor (Trametes versicolor) strain is used, and its number is: China Center for Type Culture Collection (CCTCC) 5.48, which can be provided by strain preservation institutions such as China Center for Microorganism Collection;

[0030] (2) Put 1ml of the spore suspension of Trametes versicolor (Trametes versicolor) strain into potato / glucose medium, and cultivate it at 30°C and 150-200rpm for 24-28 hours to obtain the strain culture solution;

[0031] (3) Composition of fermentation medium:

[0032] Potassium dihydrogen phosphate 2.0g / L,

[0033] Ammonium sulfate (NH4) 2 SO 4 1.4g / L,

[0034] CaCl 2 2H 2 O 0.1g / L,

[0035] MgSO 4 ·7H 2 O 0.5g / L,

[0036] Glucose 10g / L,

[0037] Trace element solution 1-10ml,

[0038] Vitamin B1 0.001g / L,

[0039] Diammonium tartrate 0.02g / L,

[0040] Poloxamer (Pluronic) F68 0-3g / L;

[0041] (4) Fermentation conditions: Inoculate the strain cul...

Embodiment 2

[0049] The production of embodiment 2 cellulolytic enzymes

[0050] (1) Trichoderma viride (Trichoderma viride) strain is used, its serial number is: 3.1912, which can be provided by strain preservation institutions such as China Center for Type Culture Collection (CCTCC);

[0051] (2) Insert 1 ml of the spore suspension of Trichoderma viride (Trichoderma viride) bacterial strain into the seed culture medium, and cultivate at 150-200 rpm for 16-24 hours at 30°C;

[0052] (3) Composition of fermentation medium:

[0053] Inorganic nutrient solution:

[0054] K H 2 PO 4 2.0g / L,

[0055]Urea 0.3g / L,

[0056] (NH4) 2 SO 4 1.4g / L,

[0057] CaCl 2 0.3g / L,

[0058] MgSO 4 ·7H 2 O 0.3g / L,

[0059] FeSO 4 ·7H 2 O 0.005g / L,

[0060] MnSO 4 ·H 2 O 0.0016g / L,

[0061] ZnSO 4 0.0014g / L,

[0062] CoCl 2 0.002g / L;

[0063] On the basis of inorganic nutrient solution, add:

[0064] Lactose 10g / L,

[0065] Glucose 10g / L,

[...

Embodiment 3

[0070] The production of embodiment 3 xylanase

[0071] (1) Aspergillus niger (Aspergillus niger) strain is used, its number is: 3.3147, which can be provided by strain preservation institutions such as China Center for Type Culture Collection (CCTCC);

[0072] (2) Inject 1 ml of the spore suspension of Aspergillus niger into the potato / glucose seed culture medium, and cultivate at 150-200 rpm for 16-24 hours at 30°C;

[0073] (3) Composition of fermentation medium:

[0074] Inorganic nutrient solution:

[0075] K H 2 PO 4 2.0g / L,

[0076] (NH4) 2 SO 4 1.4g / L,

[0077] CaCl 2 0.3g / L,

[0078] MgSO 4 ·7H 2 O 0.3g / L,

[0079] FeSO 4 ·7H 2 O 0.005g / L,

[0080] MnSO 4 ·H 2 O 0.0016g / L,

[0081] ZnSO 4 0.0014g / L,

[0082] CoCl 2 0.002g / L;

[0083] Fermentation medium: based on inorganic nutrient solution, adding

[0084] Peptone 1g / L,

[0085] Lactose 10g / L,

[0086] Pluronic F68 1g / L;

[0087] (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com