High-sensitivity photosensitive gas sensor and preparation method thereof

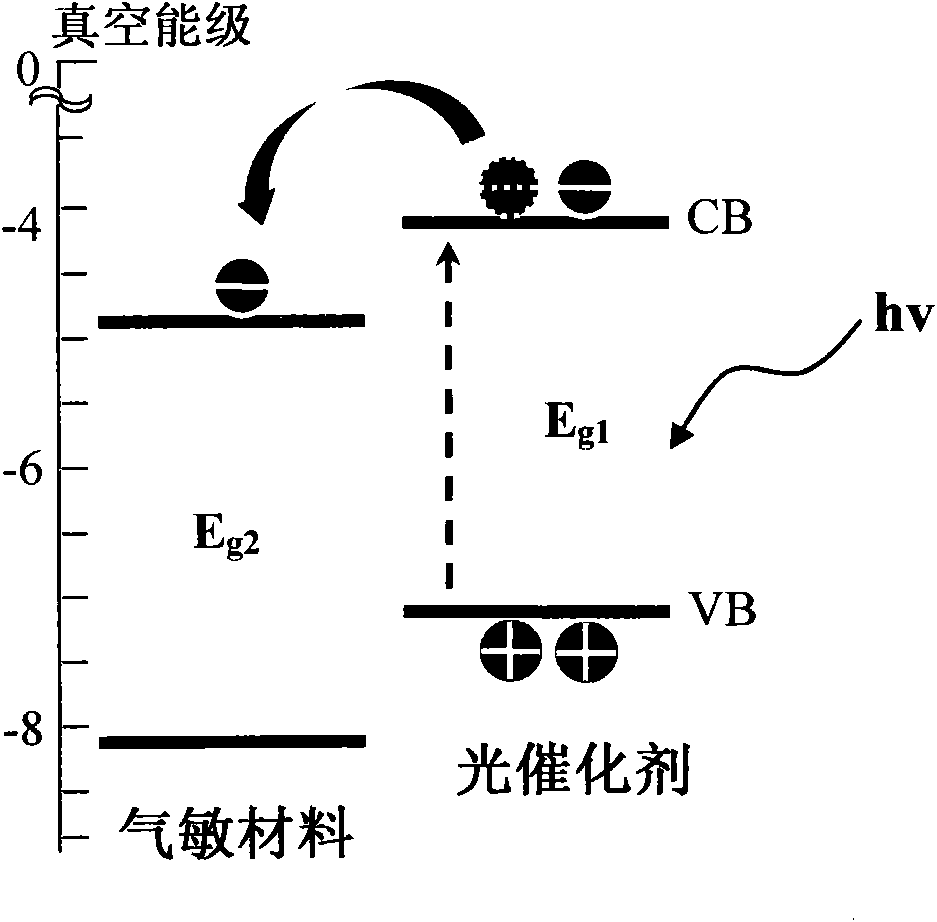

A gas sensor, high-sensitivity technology, used in instruments, scientific instruments, material analysis by optical means, etc., can solve problems such as low sensitivity, and achieve the effects of improving sensitivity, good response, and improving light efficiency and gas sensing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

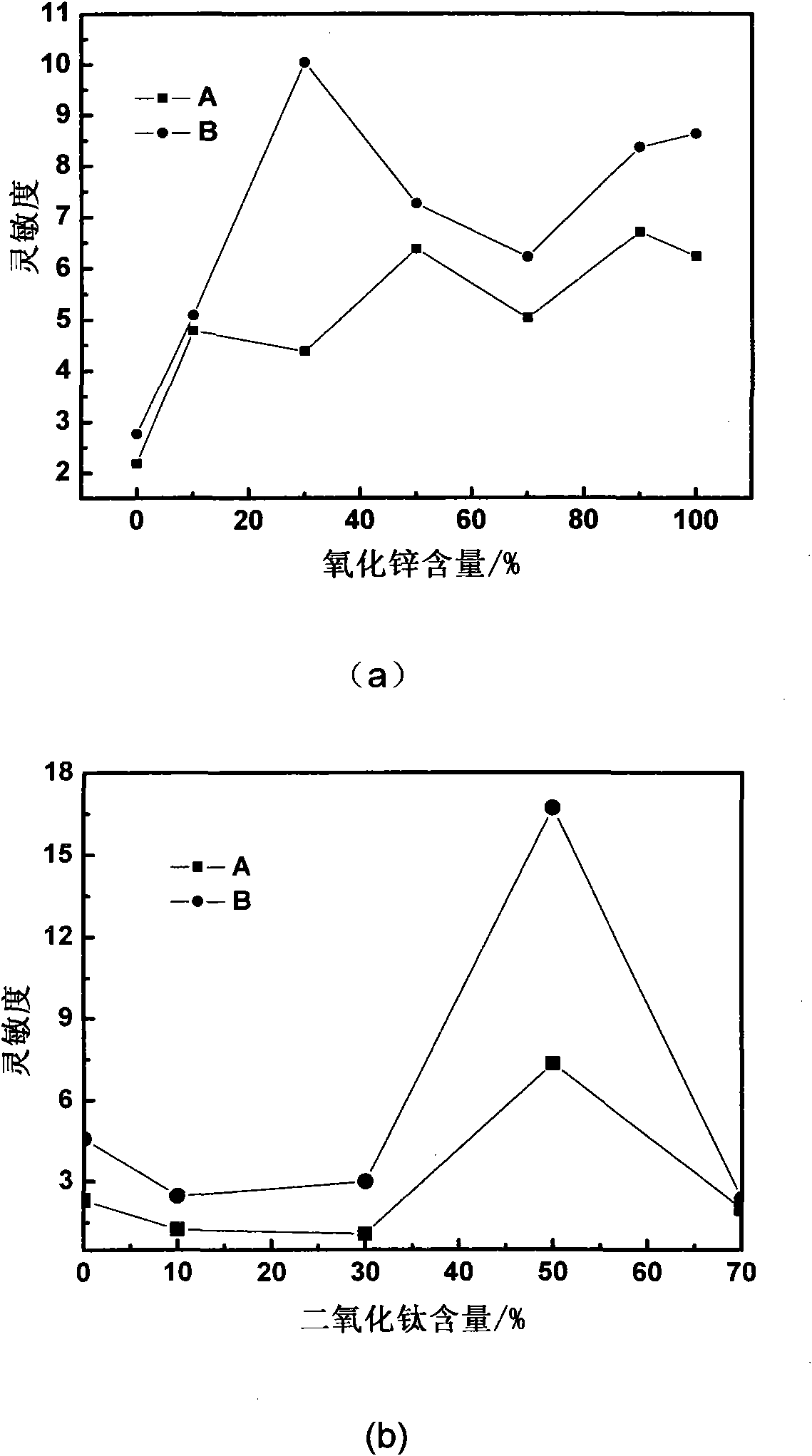

[0040] With the ZnO prepared by the method in Comparative Example 2, the SnO prepared by the method in Comparative Example 1 2 According to the mass ratio of 1:9, the composite material was firstly dry-milled for 2 hours, and then deionized water was added to wet-mill for 30 minutes to form a paste, which was set aside.

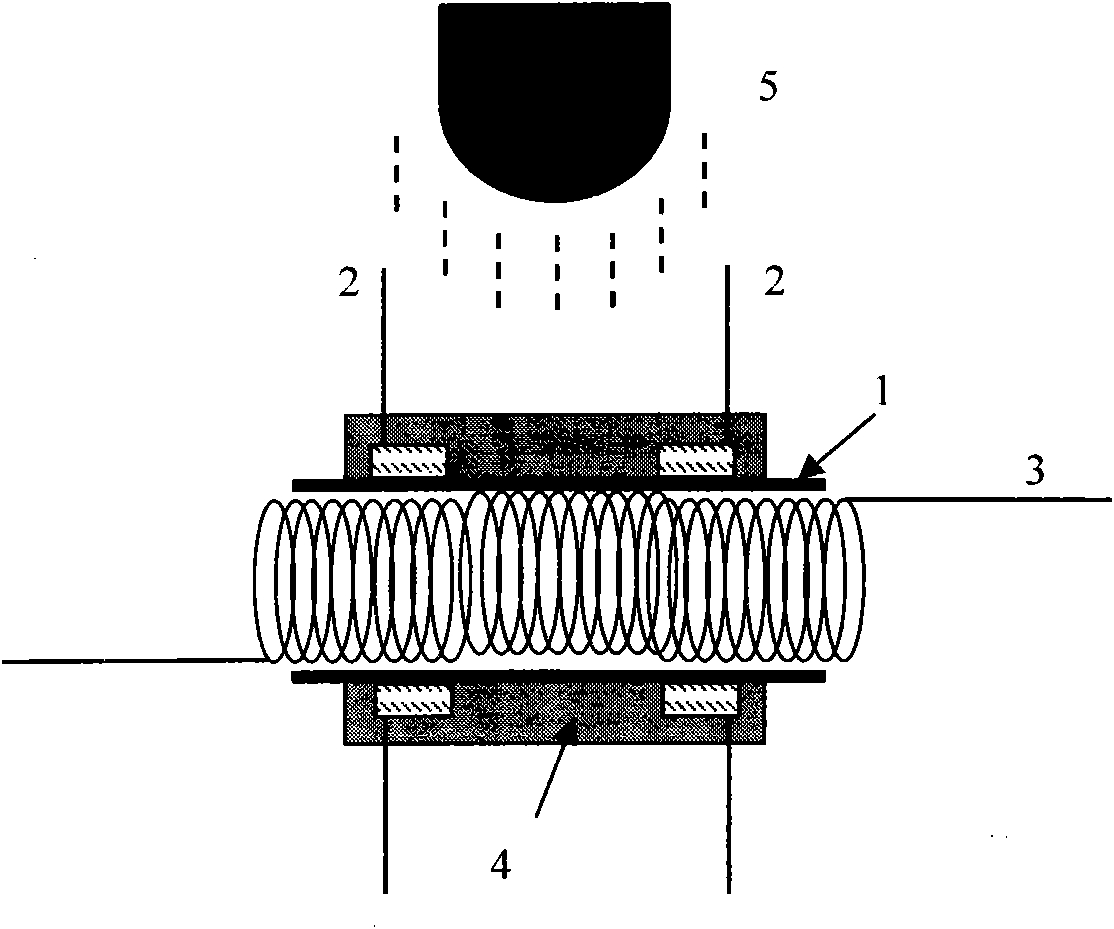

[0041] Select Al with a tube length of 4mm, a wall thickness of 0.2mm, an outer diameter of 1.2mm, and an inner diameter of 0.8mm 2 o 3 The ceramic tube is the substrate 1, and the gold ring and platinum wire are the electrodes 2 (purchased from Siping Semiconductor Factory). Spin-coating ZnO and SnO 2 The paste with a mass ratio of 1:9 was uniformly coated on the Al 2 o 3 After being air-dried, put it into a muffle furnace for sintering at 600°C for 2 hours, and then cool it down to room temperature naturally. Pass a 30Ω Ni-Cr heating coil 3 through the cooled ceramic tube with a sensitive body 4 as a heater to obtain a gas sensor. The ultraviolet ligh...

Embodiment 2

[0043] The device structure and preparation method are the same as in Example 1, except that ZnO and SnO 2 The mass ratio is 3:7.

Embodiment 3

[0045] The device structure and preparation method are the same as in Example 1, except that ZnO and SnO 2 The mass ratio is 5:5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com