Emulsion polymers, aqueous dispersions and method for producing the same

A technology of emulsion polymers and mixtures, which is applied in transportation, packaging, thin material handling, etc. It can solve the problems of low storage capacity and achieve the effects of low residual monomer content, improved open time, and high adhesion strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

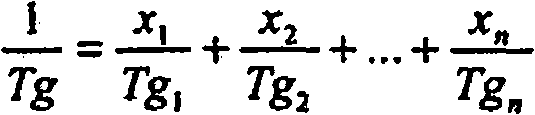

Method used

Image

Examples

Embodiment 1

[0121] First, 172 g of butyl acrylate (BA), 128 g of methyl methacrylate (MMA), 80 g of methacryloyloxy-2-hydroxypropyl- Oleate, 20 g methacrylic acid (MAS), 1.2 g ammonium peroxodisulfate (APS), 12.0 g Disponil FES 32 (30% strength) and 359.18 g water were emulsified for 3 minutes. Methacryloxy-2-hydroxypropyl-linoleate is obtained by reacting linoleic acid with glycidyl methacrylate.

[0122] Into a 2 liter glass reactor tempered with a water bath and equipped with a paddle stirrer, 230 g of water and 0.3 g of Disponil FES 32 (30% strength) were initially charged and this initial charge was heated to 80° C. and mixed with 0.3 g Ammonium peroxodisulfate (APS) (in dissolved form in 10 g of water) was blended. 5 minutes after the addition of the APS, the previously prepared emulsion was metered in within 240 minutes (interval: 3 minutes feed, 4 minutes pause, 237 minutes remainder feed).

[0123] After the feed was complete, the batch was post-stirred at 80° C. for 1 hour. T...

Embodiment 2

[0131] Example 1 was essentially repeated, but in which 80 g of methacryloxy-2-hydroxypropyl-oleate were used. The methacryloxy-2-hydroxypropyl oleate is obtained by reaction of oleic acid with glycidyl methacrylate.

[0132] The prepared emulsion had a solids content of 40±1%, a pH of 2.5, a viscosity of 16 mPas and an r of 71 nm N5 value.

[0133] The results obtained with the analytical methods described above are given in Table 1.

[0134] For comparison, commercially available alkyd resins were investigated, wherein as comparative example 1, an alkyd resin commercially available from the company Worlée under the trade name E 150W was investigated, and as comparative example 2, Xyladecor, manufactured by ICI Company sales. The results obtained are described in Table 1.

Embodiment 3

[0143]Example 1 was essentially repeated, wherein the dispersion was prepared via the miniemulsion method. For this purpose, 400 g of butyl acrylate, 390 g of methyl methacrylate, 200 g of methacryloyloxy-2-hydroxypropyl-linoleate and 10 g of methacrylic acid were emulsified with 20 g of sodium lauryl sulfate. As a hydrophobic agent, 4% hexadecane was additionally added. The polymerization was initiated at 75°C with 1% AIBN. The obtained dispersion has an r of 51 nm N5 value and a pH of 4.1. The coating formed from this dispersion showed a weight loss in MIBK of 11.7%, a water absorption after 24h of 22.8% and a tensile strength of 5.1 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com