Preparation method of self-supporting colloid photon crystal film

A colloidal photonic crystal, self-supporting technology, applied to the device of coating liquid on the surface, special surface, pre-treated surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

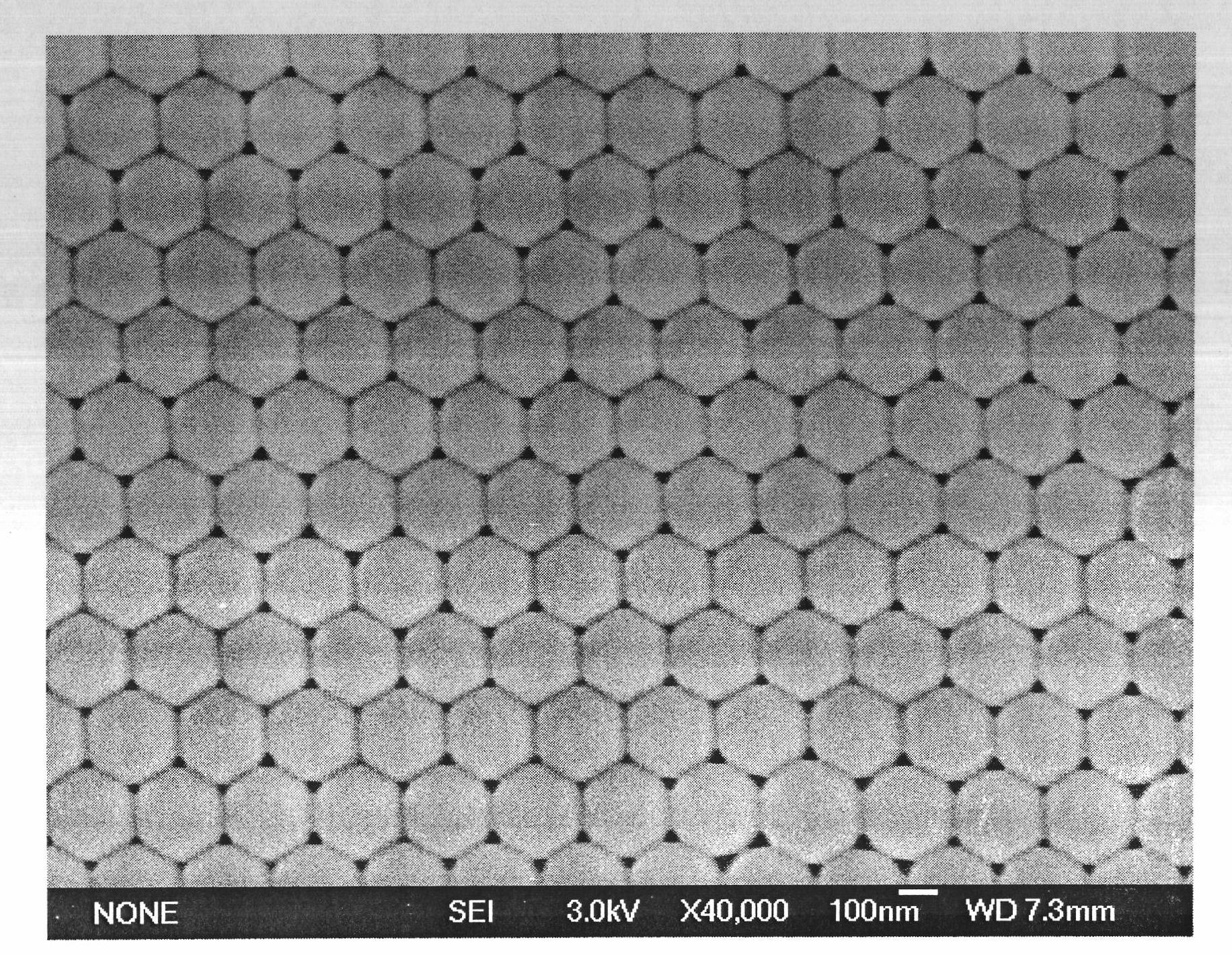

Embodiment 1

[0036] Spin-coat the mixed solution containing polymerizable monomers (acrylamide 1wt%, ammonium persulfate 0.1wt%, N,N-methylenebisacrylamide 0.1wt%, water 98.8wt%) evenly on the glass at a speed of 500rpm The elastic hydrogel substrate was obtained by thermal cross-linking polymerization at 60°C for 1 hour. The mixture aqueous solution (acrylamide 1wt%, ammonium persulfate 0.1wt%, N, N-methylenebisacrylamide 0.1wt%) of the mixture aqueous solution of monodisperse latex particle and monomer, particle diameter is the monodisperse polystyrene latex particle of 100nm 40wt%, water 58.8wt%) evenly drop-coated on the above-mentioned elastic hydrogel substrate; after placing the obtained sample at 90 ℃ and the relative air humidity of 60RH% for 5 hours, a self-supporting colloidal photonic crystal was obtained membrane.

Embodiment 2

[0038] The mixed solution containing polymerizable monomers (acrylic acid 40wt%, potassium persulfate 5wt%, N, N-methylenebisacrylamide 5wt%, water 50wt%) was uniformly spin-coated on a silicon wafer at a speed of 2000rpm, and then Thermal cross-linking polymerization at 70°C for 1 hour to obtain an elastic hydrogel substrate. The mixture aqueous solution (20wt% of acrylic acid, 5wt% of potassium persulfate, 5wt% of N, N-methylenebisacrylamide, 0.5wt% of monodisperse silica latex particles with a particle size of 300nm) , water 69.5wt%) evenly drop-coated on the above-mentioned elastic hydrogel substrate; after placing the obtained sample at 60° C. and the relative air humidity of 30RH% for 2 hours, a self-supporting colloidal photonic crystal film was obtained.

Embodiment 3

[0040] Evenly drop-coat the mixed solution containing polymerizable monomers (20wt% methacrylic acid, 2wt% hydrogen peroxide, 2wt% N, N-methylenebisacrylamide, 76wt% water) on a stainless steel sheet, heat it at 30°C The cross-linking polymerization was carried out for 3 hours to obtain an elastic hydrogel substrate. Then the mixture aqueous solution of monodisperse latex particle and monomer (methacrylic acid 10wt%, hydrogen peroxide 3wt%, N, N-methylenebisacrylamide 3wt%, particle diameter is the monodisperse poly(styrene- Methyl methacrylate-acrylic acid) latex particle 20wt%, water 64wt%) uniform roller coating on the above-mentioned elastic hydrogel substrate; Gained sample is placed 12 hours under the condition of 30 ℃ and relative air humidity of 90RH% Finally, a self-supporting colloidal photonic crystal film is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com