System for disassembling waste refrigeration plants and recycling materials

A refrigeration equipment and recovery system technology, applied in waste treatment, solid waste removal, grain treatment, etc., can solve the problems of low quality of recycled by-products, low resource reuse rate, environmental pollution, etc., and achieve good environmental protection benefits and social benefits. Benefits, safe and stable operation, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

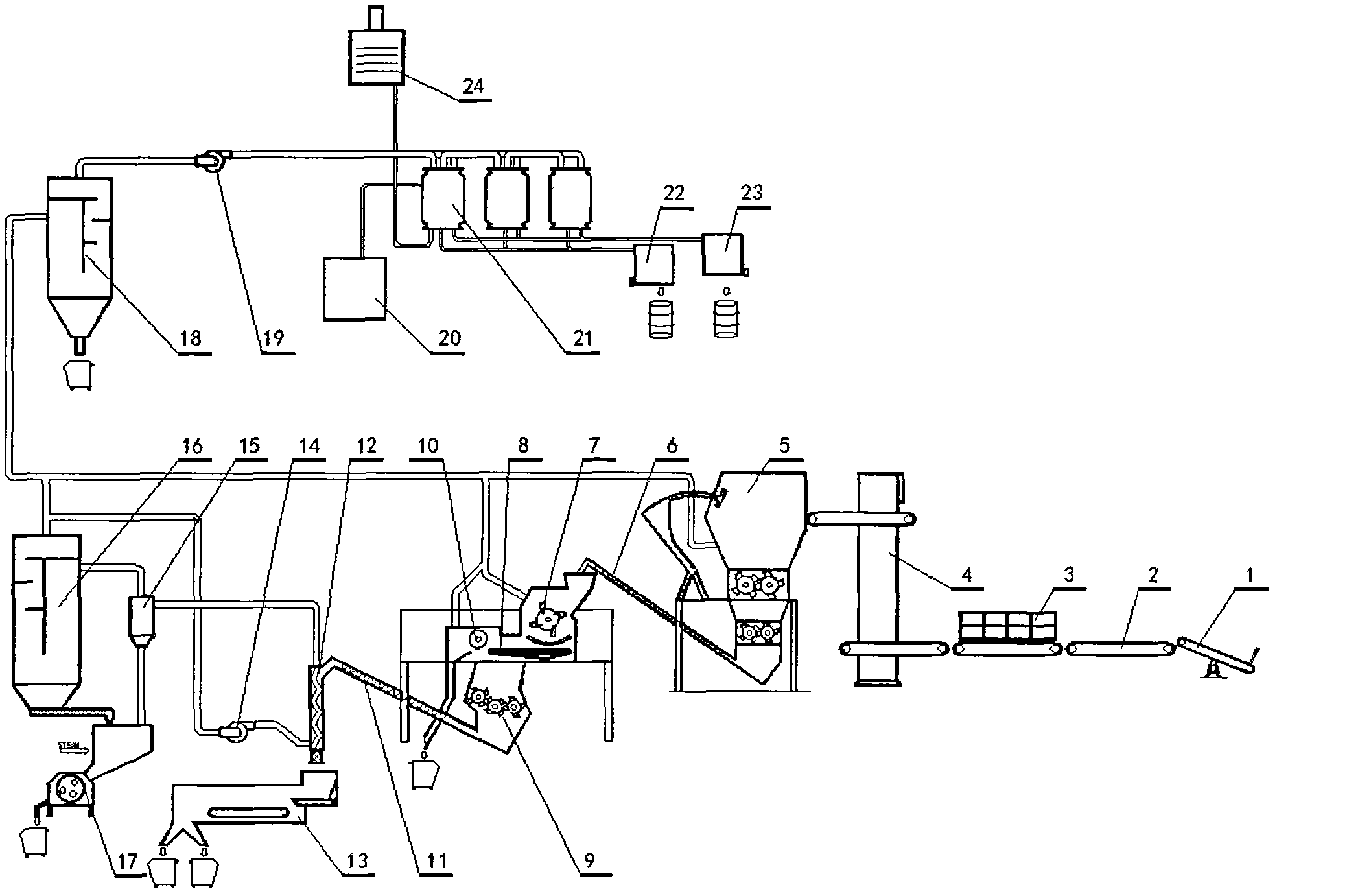

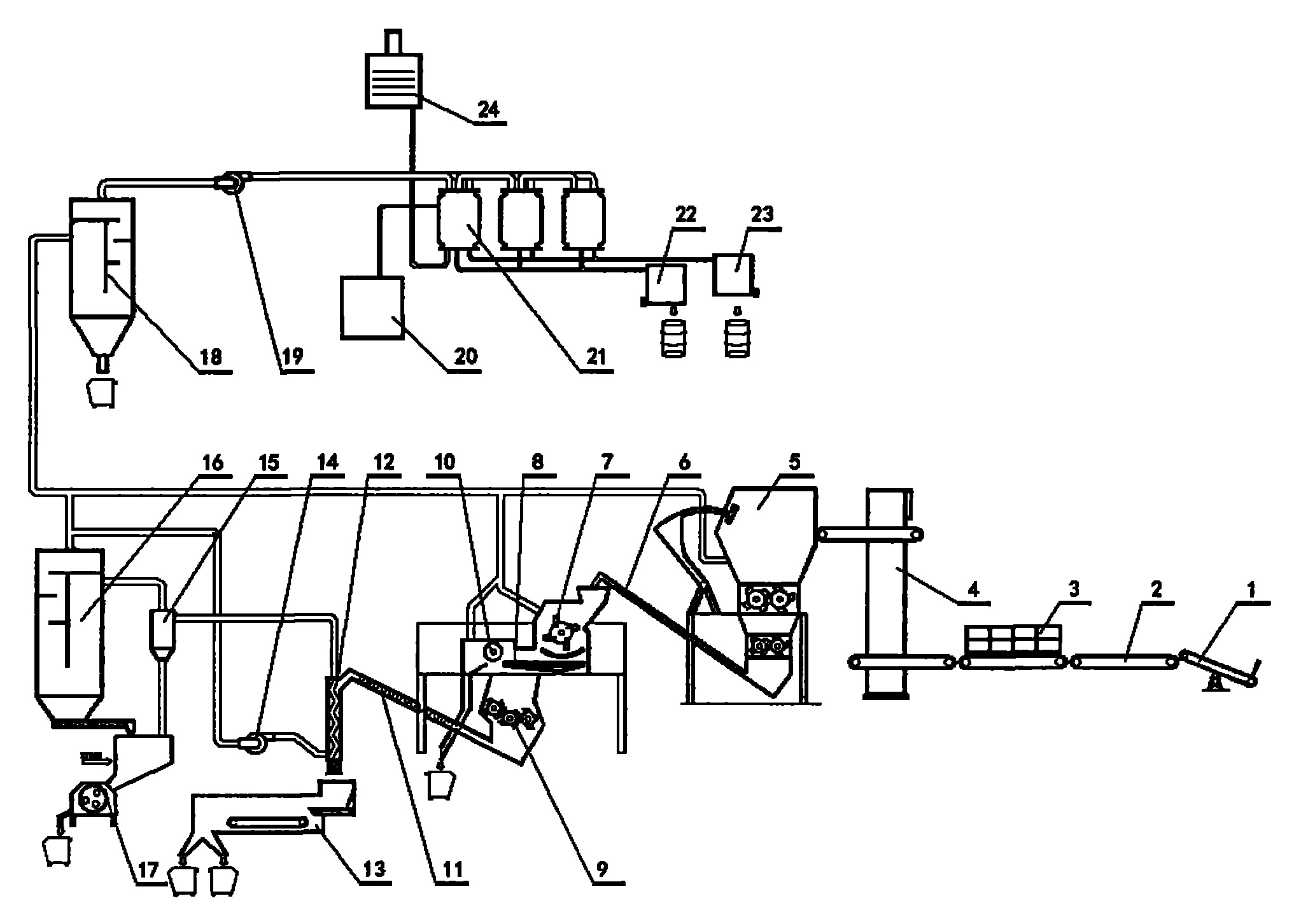

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0010] see Attachment.

[0011] The dismantling and recycling system of waste refrigeration equipment consists of a pre-dismantling system, a crushing and separation subsystem and a post-processing system. The pre-dismantling system consists of a loading mechanism 1, a horizontal roller conveyor 2, a horizontal roller conveyor 3, and a vertical lifting platform 4 structure, the rear end of the loading mechanism 1 is equipped with a horizontal roller conveyor 2, and the middle section of the horizontal roller conveyor 2 is equipped with a CFC-OIL separation operation table 3, and the CFC-OIL separation operation table 3 is tiltable, and the horizontal roller conveyor 2. A vertical lifting platform 4 is arranged at the rear end, and the vertical lifting platform 4 is arranged at the front end of the feeding port of the two-stage twin-shaft crusher 5 in the crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com