Endless belt with slits for sheet belt coiling tension offering device

A technology of coiling tension and coiling device, which is applied in the direction of coiling strips, transportation and packaging, and thin material processing, etc. The effect of slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The best mode for carrying out the present invention is described in detail with the accompanying drawings as follows.

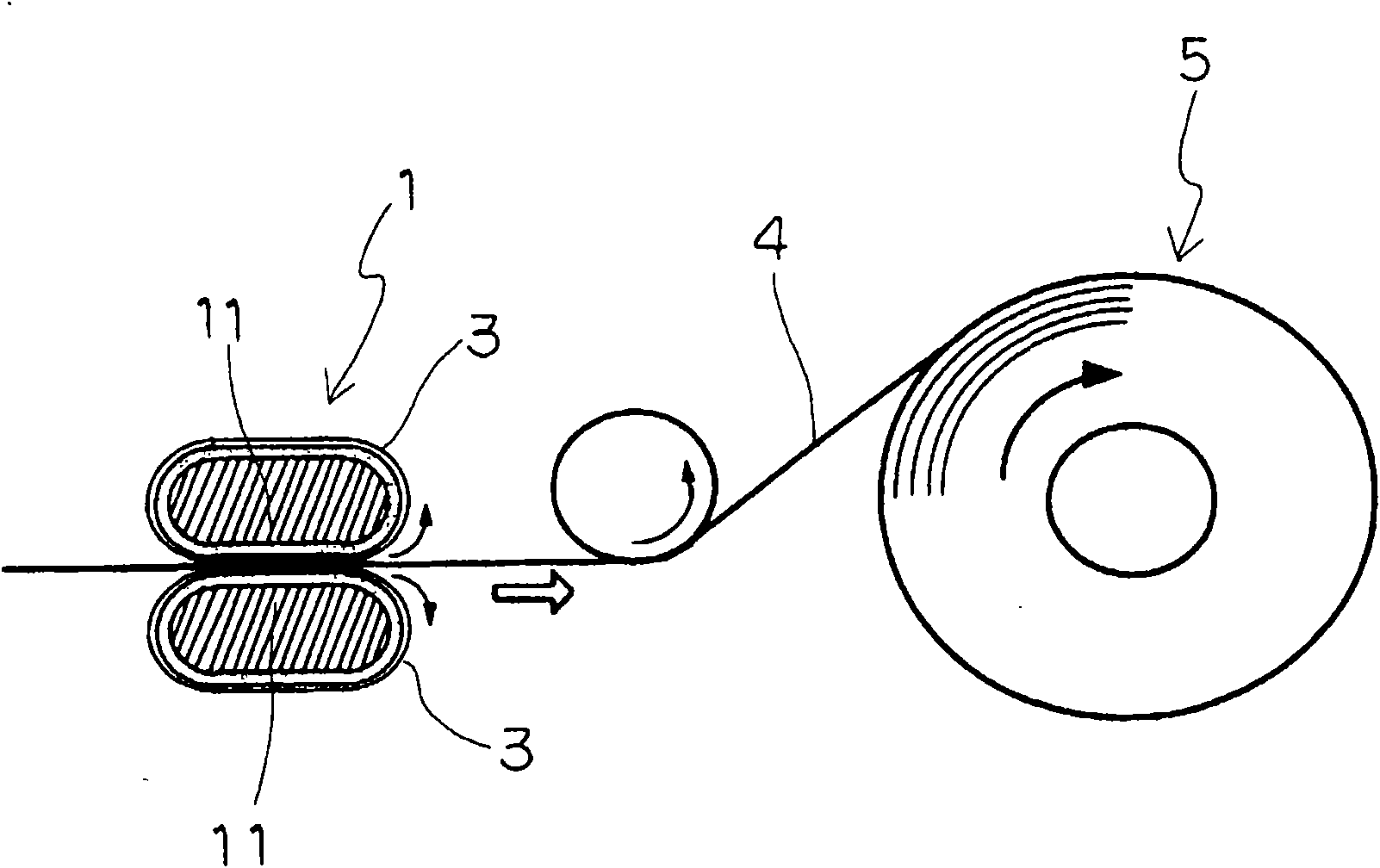

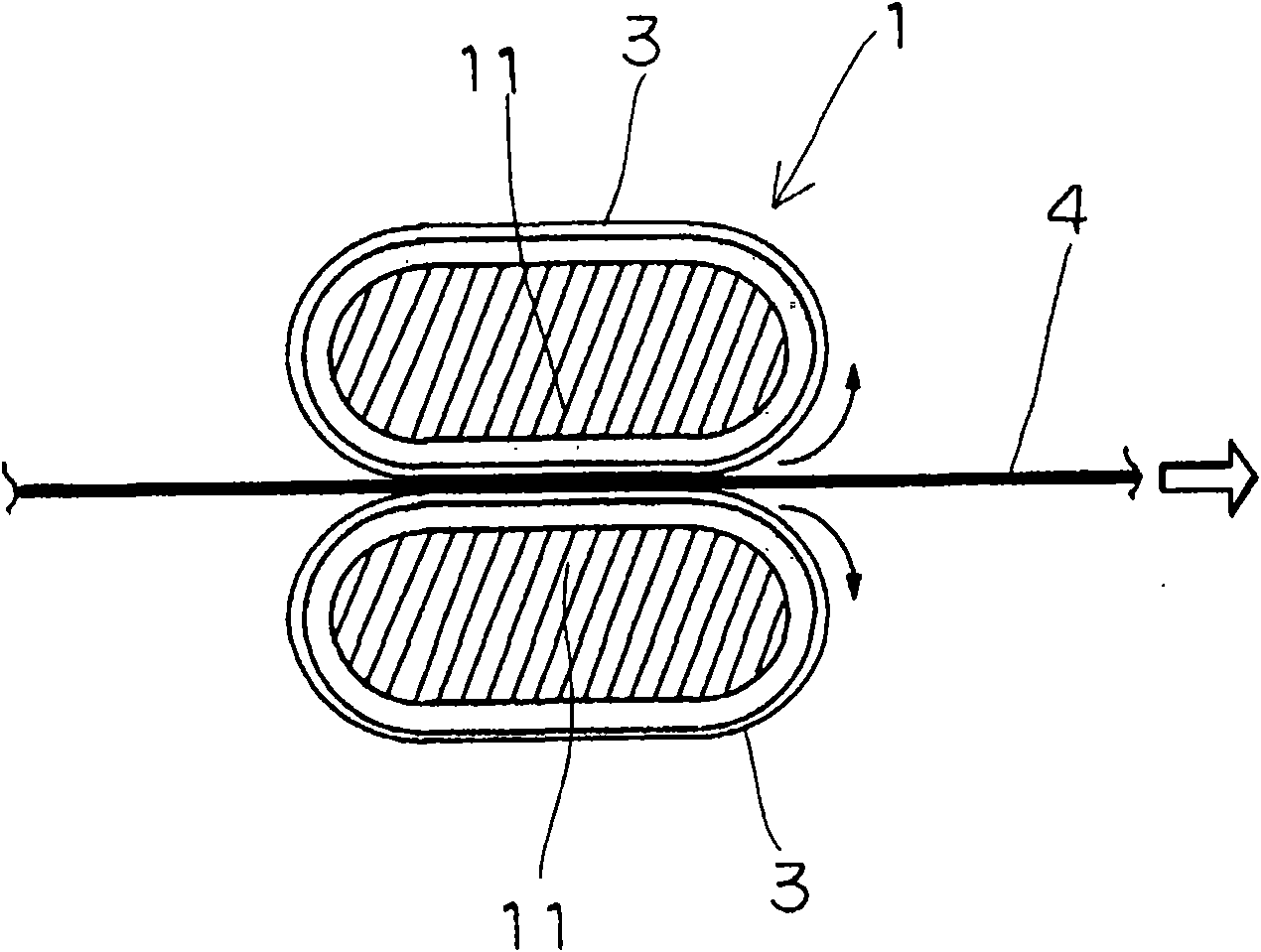

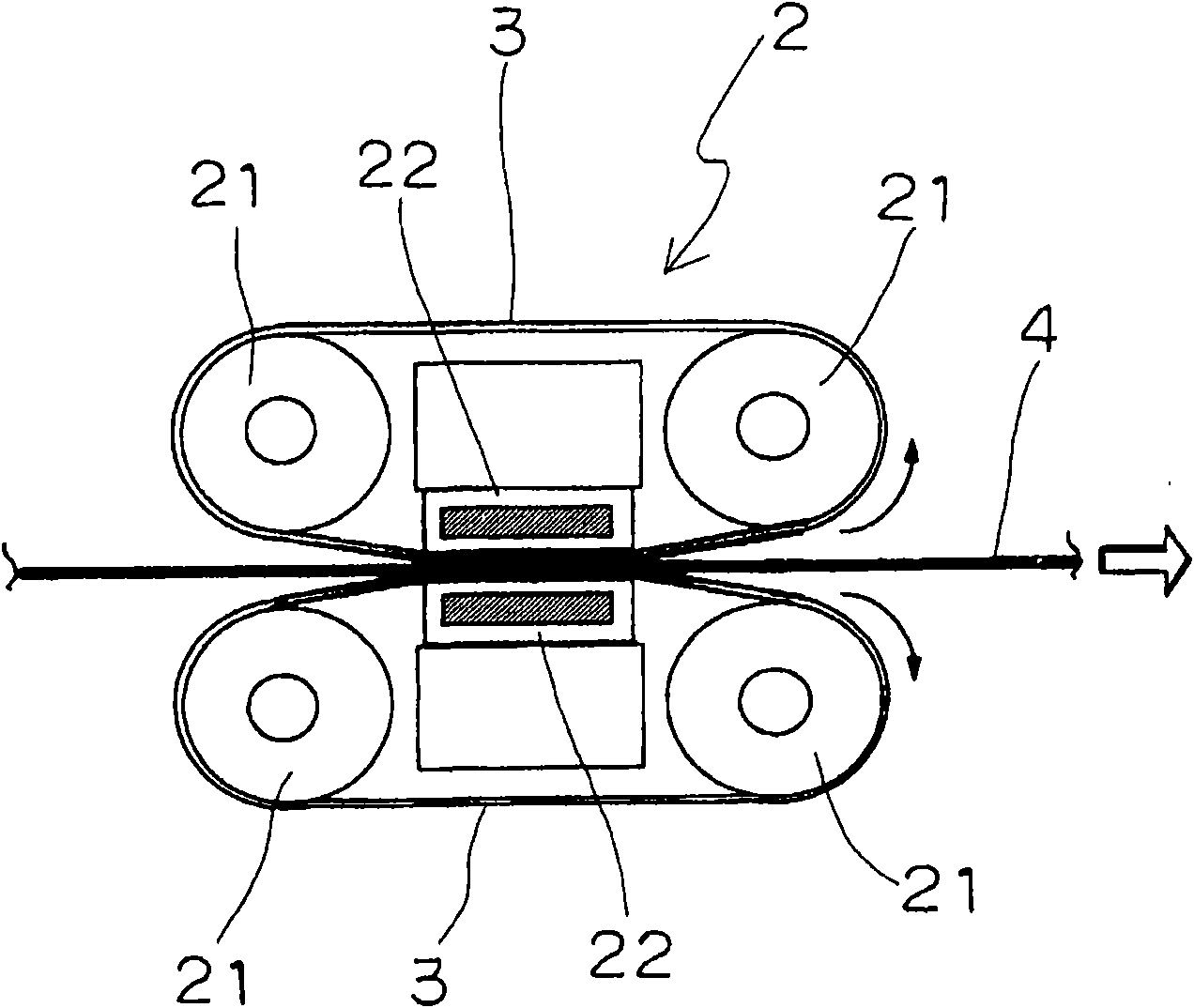

[0064] 1 and 2 in the figure are belt-type strip winding tension imparting devices, which are devices for applying (applying) a predetermined winding tension to the metal strip 4 via the endless belt 3 . Such as figure 1 As shown, these tension imparting devices 1, 2 ( figure 1 The belt-type strip coiling tension applying device 1 is illustrated as an example to wind the strip 4 installed in front of the strip coiling device 5 in the middle of the moving path. Such a tension imparting device, for example, has been figure 1 and figure 2 The so-called "Oval Form (Patent No. 3679730)" shown, or as image 3 Shown "pulley (pulley) type (Patent No. 1361033)" and other types.

[0065] in, figure 1 and figure 2 The shown elliptical belt-type strip coiling tension imparting device 1 is mainly composed of a pressure application body 11 for pushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com