Double-frequency ultrasonic chemical reactor

A chemical reactor and dual-frequency ultrasonic technology, which is applied in the field of wastewater treatment devices and dual-frequency ultrasonic chemical reactors, can solve the problem that the structure is too simple, cannot maximize the effect of dual-frequency ultrasonic wastewater treatment, and cannot meet the requirements of continuous wastewater treatment, Long-term requirements and other issues, to achieve the effect of prolonging the ultrasonic response time, promoting the ultrasonic cavitation benefit, and increasing the ultrasonic cavitation benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

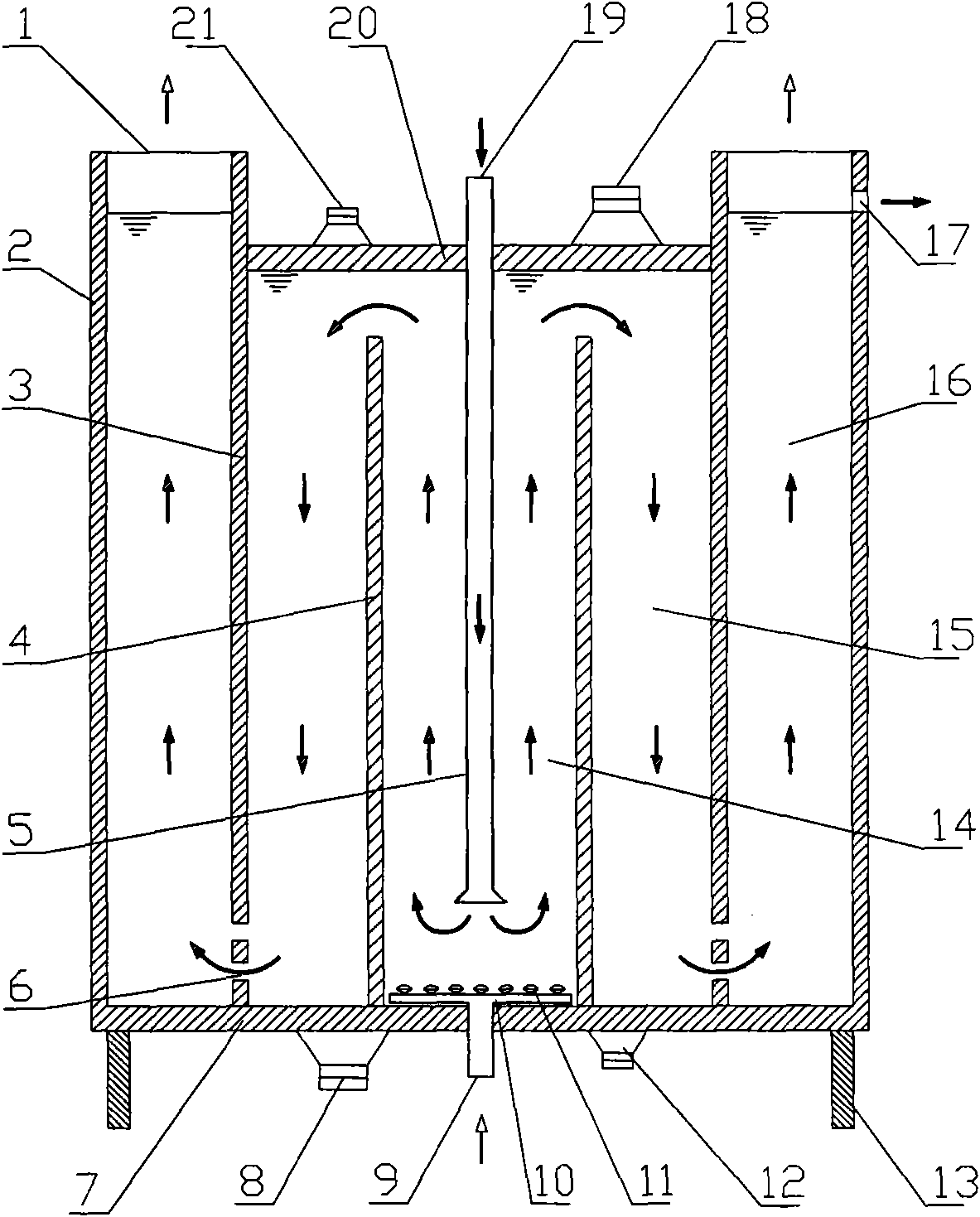

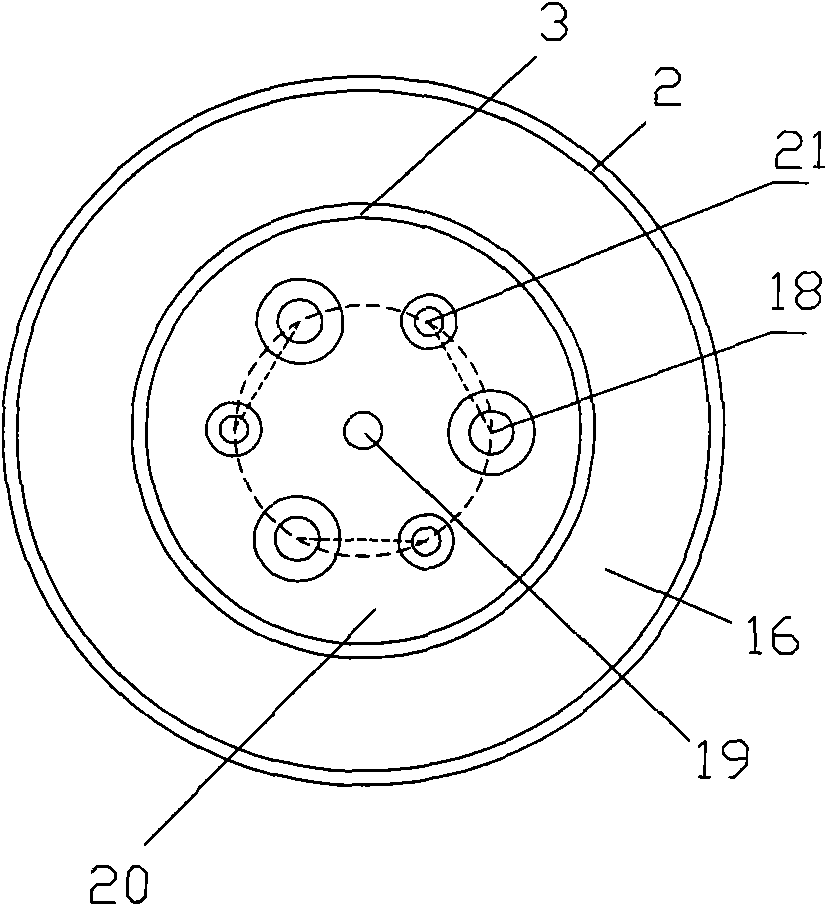

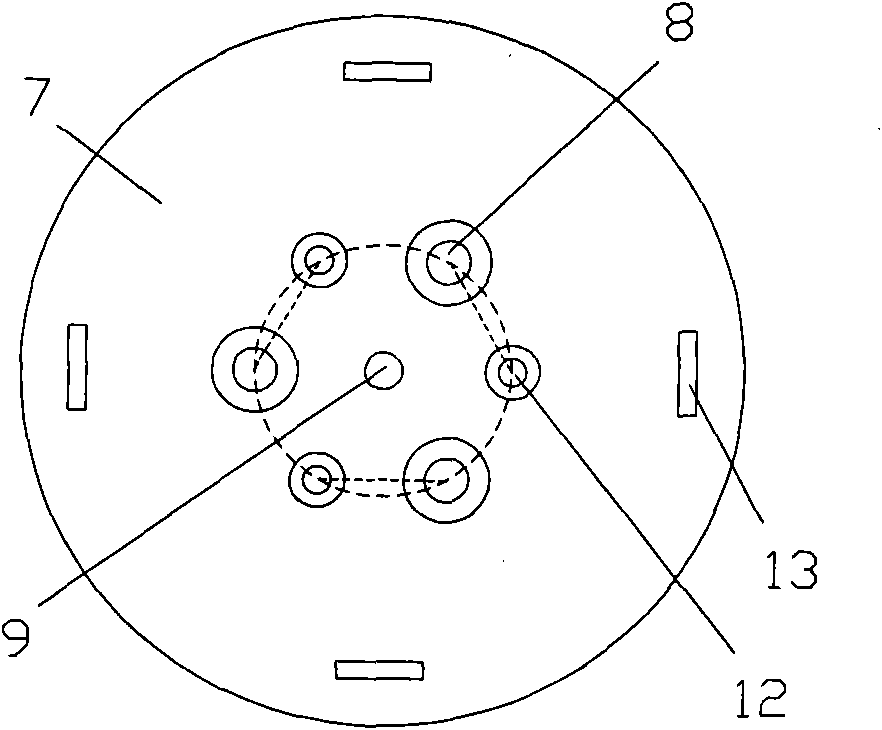

[0028] see figure 1 , figure 2 , image 3 with Figure 4 , in this embodiment, the reactor adopts a cylinder structure, including an outer cylinder 2, an inner cylinder 3, a bottom plate 7, a lifting cylinder 4 in the inner cylinder 3, and a water inlet pipe 5, and the water outlet 17 is arranged on the side of the outer cylinder 2 On the wall; a cover plate 20 is placed above the inner cylinder 3, and the height of the cover plate 20 is lower than the height of the water outlet 17; two sets of ultrasonic transducers placed outside the cylinder are respectively arranged on the cover plate 20 and the bottom plate 7 ; Among the two groups of ultrasonic transducers, one group is spaced from the top high-frequency ultrasonic transducer 18 and the top low-frequency ultrasonic transducer 21 and is evenly distributed on the cover plate 20; the other group is composed of the bottom high-frequency ultrasonic transducer The transducer 8 and the bottom low-frequency ultrasonic transd...

Embodiment 2

[0034] The overall structure of the reactor in this embodiment is the same as in Embodiment 1, except that the arrangement of the top high-frequency ultrasonic transducer 18 and the top low-frequency ultrasonic transducer 21 on the cover plate 20 is as follows: Figure 5 As shown, the layers are evenly arranged in circular rings, that is, they are uniformly distributed on each layer of circular rings. Actually, the number of layers of transducers can be set correspondingly according to the area of the cover plate 20, which can be 2 to 5 layers. Correspondingly, the arrangement of the bottom high-frequency ultrasonic transducer 8 and the bottom low-frequency ultrasonic transducer 12 is as follows Image 6 shown.

[0035] Aerator 11 presses in the present embodiment Figure 7 Shown in a mesh arrangement.

[0036] The reaction process of the waste water of the reactor during operation is the same as that of Example 1.

[0037] In a specific implementation, the two groups of ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com