Process for recycling alkali waste etching liquid

An etching liquid and alkaline technology, applied in the field of waste liquid recycling process, can solve the problems of increasing the burden on enterprises, difficult to handle qualified, and the waste liquid cannot be recycled, and achieves the effect of reducing treatment costs and production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

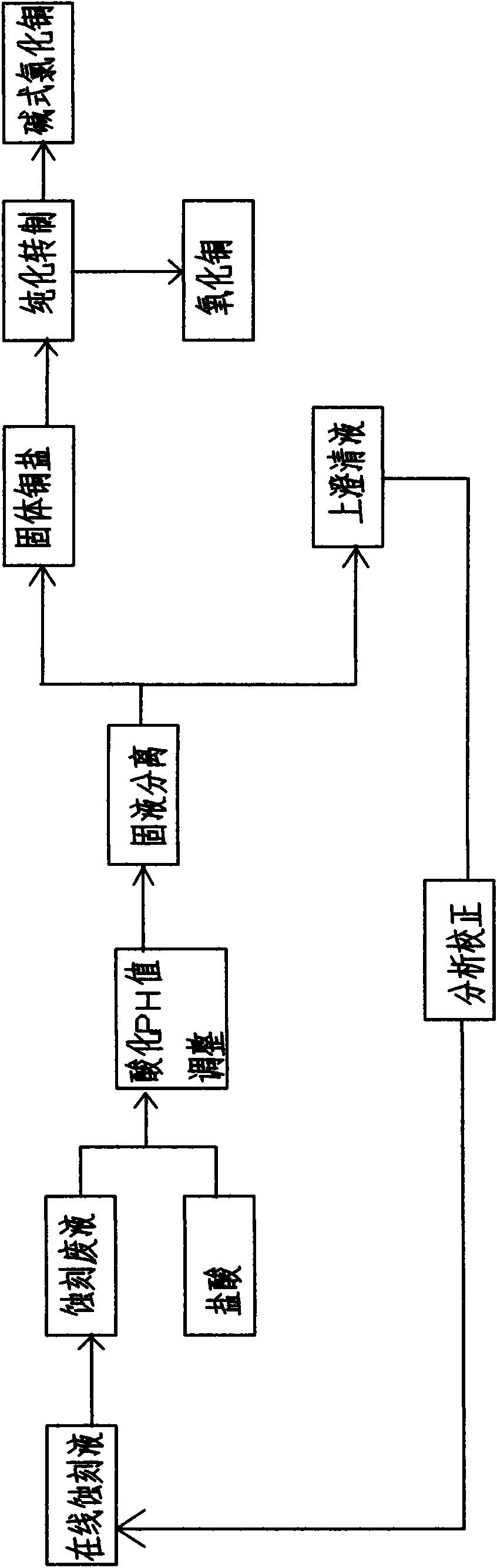

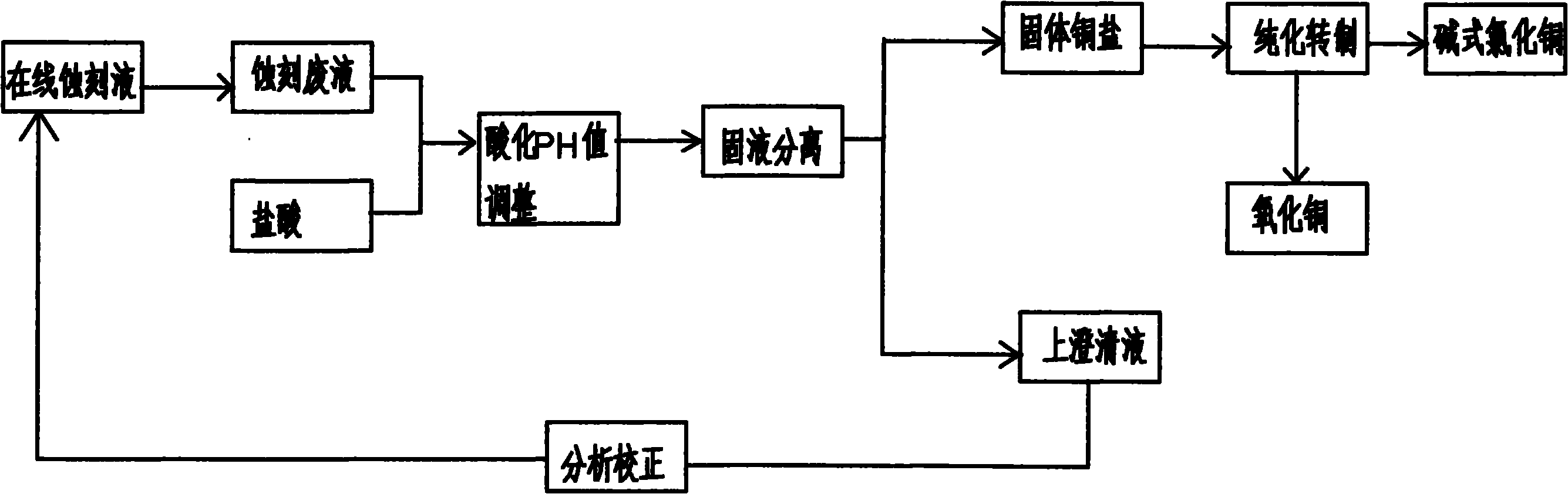

[0017] like figure 1 As shown, it is a process flow diagram of the present invention, and this alkaline etching waste liquid recycling process comprises the following steps:

[0018] a) Acidification and pH adjustment, add hydrochloric acid and sedimentation agent to the alkaline etching solution, adjust the pH value to make the copper salt in the alkaline etching solution settle; the adjustment range of the pH value is 4.0-6.0. When the pH value is between 5.5 and 6.0, the chloride (the mixed crystal structure of cupric chloride and ammonium chloride) is relatively pure, which is conducive to the production of relatively scarce basic cupric chloride.

[0019] b) solid-liquid separation, using mechanical method to separate solid copper salt, adding purifying agent to the separated upper layer liquid or removing other metal contamination by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com