Potassium-calcium biological composite foliar fertilizer and preparation method and application thereof

A foliar fertilizer and biological technology, applied in the field of potassium-calcium biological compound foliar fertilizer and its preparation, can solve the problems of low absorption rate of potassium and calcium, waste of labor, etc., to improve nutrient supply, reduce production cost, and nutrient utilization rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Preparation of powder yeast organic raw materials

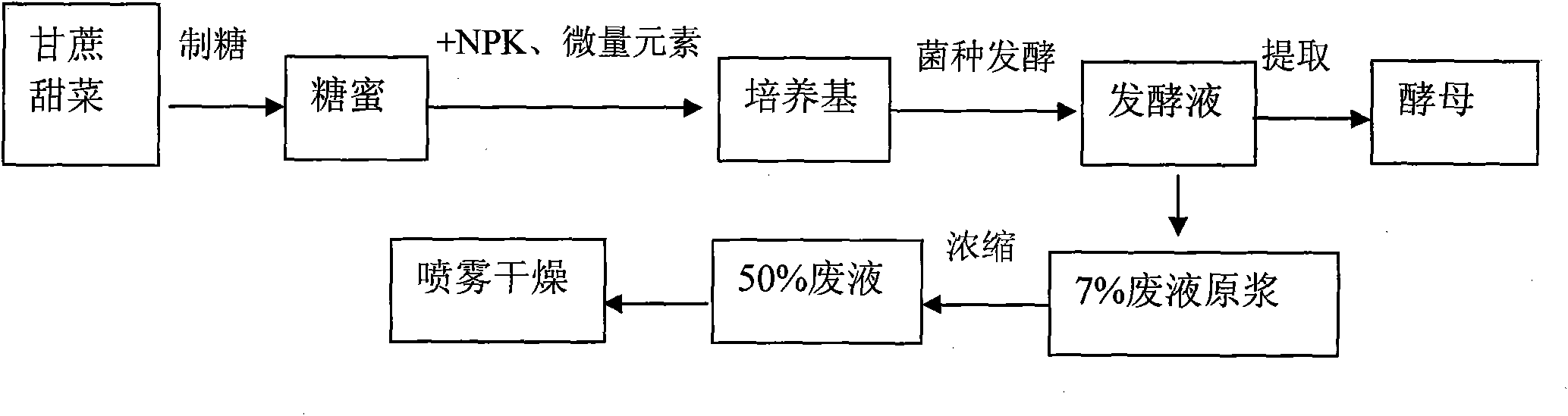

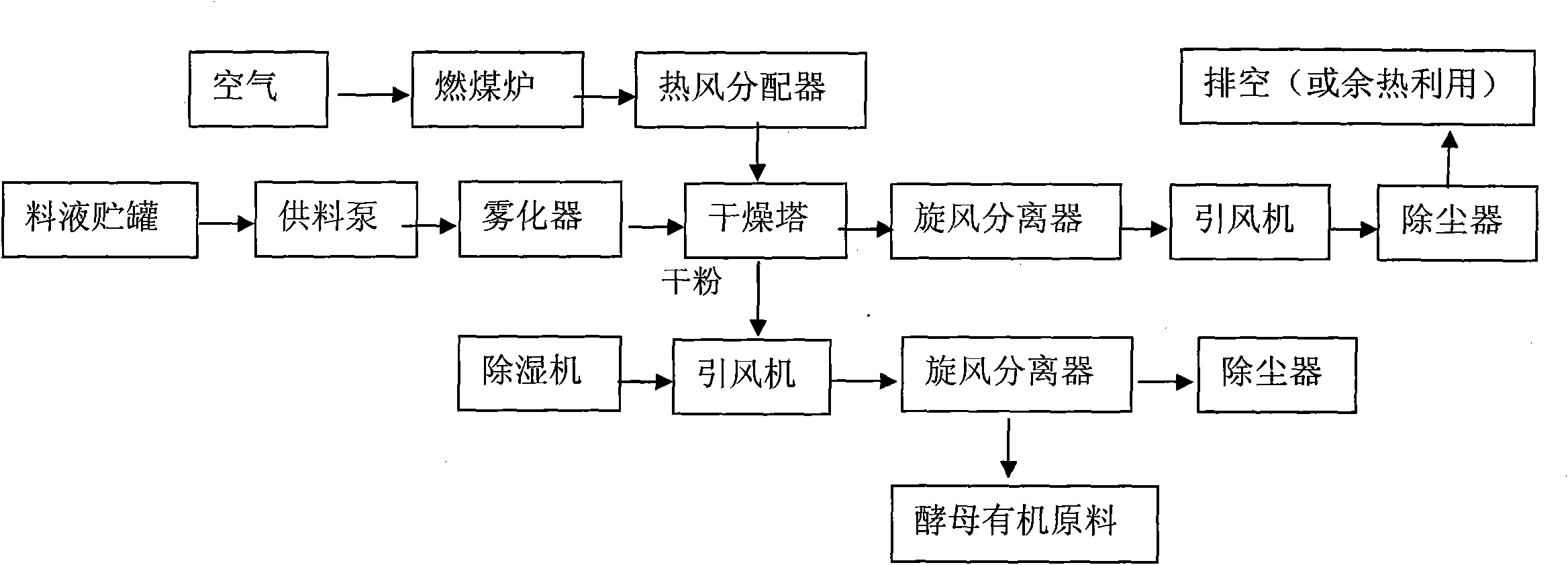

[0045]Concentrate the fermented liquid waste liquid puree after yeast extraction, the concentration of the waste liquid waste liquid puree is about 7%, after concentration, the concentration reaches 50%, and then through the spray drying process, the fineness is greater than 80 mesh, and the water content is less than 3%. Brown powder yeast organic raw material. (The process flow chart of waste liquid output in the yeast production process can be found in figure 1 ).

[0046] The basic properties of the powdery yeast organic material after spray drying are shown in Table 1. figure 2 ).

[0047] Table 1 Basic character of powdery yeast organic raw material

[0048]

[0049] 2. Strain fermentation

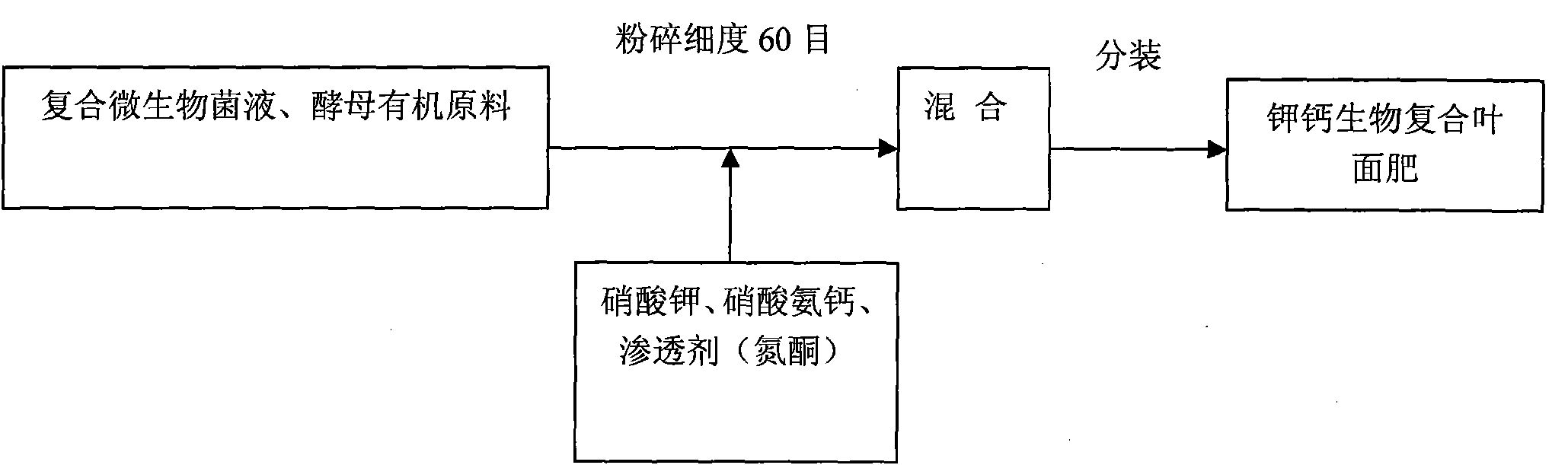

[0050] Bacillus subtilis and Bacillus mucilaginosus are fermented and produced separately using fermentation equipment, and the two strains are respectively subjected to slant culture, shaker expansion culture, se...

Embodiment 2

[0066] In the preparation of the composite microbial agent, the mixing ratio of Bacillus subtilis and Bacillus mucilaginosus after fermentation is 3:1, and the adsorption ratio of bacterial liquid and yeast organic material is 1:20.

[0067] The addition ratio of yeast organic raw material is 40%, potassium nitrate 24.5%, calcium ammonium nitrate 35%; Others are the same as embodiment 1.

Embodiment 3

[0069] In the preparation of the composite microbial agent, the mixing ratio of Bacillus subtilis and Bacillus mucilaginosus after fermentation is 2:1, and the adsorption ratio of bacterial liquid and yeast organic material is 1:40.

[0070] The addition ratio of yeast organic raw materials is 20%, potassium nitrate 39.5%, and calcium ammonium nitrate 45%. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com