Method for preparing m-nitrochlorobenzene, o-nitrochlorobenzene and p-nitrochlorobenzene by using nitrochlorobenzene meta-position oil

A technology of nitrochlorobenzene meta-oil and p-nitroanisole, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., and can solve problems such as insufficient purity, pollution of the atmospheric environment, and difficulty in implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

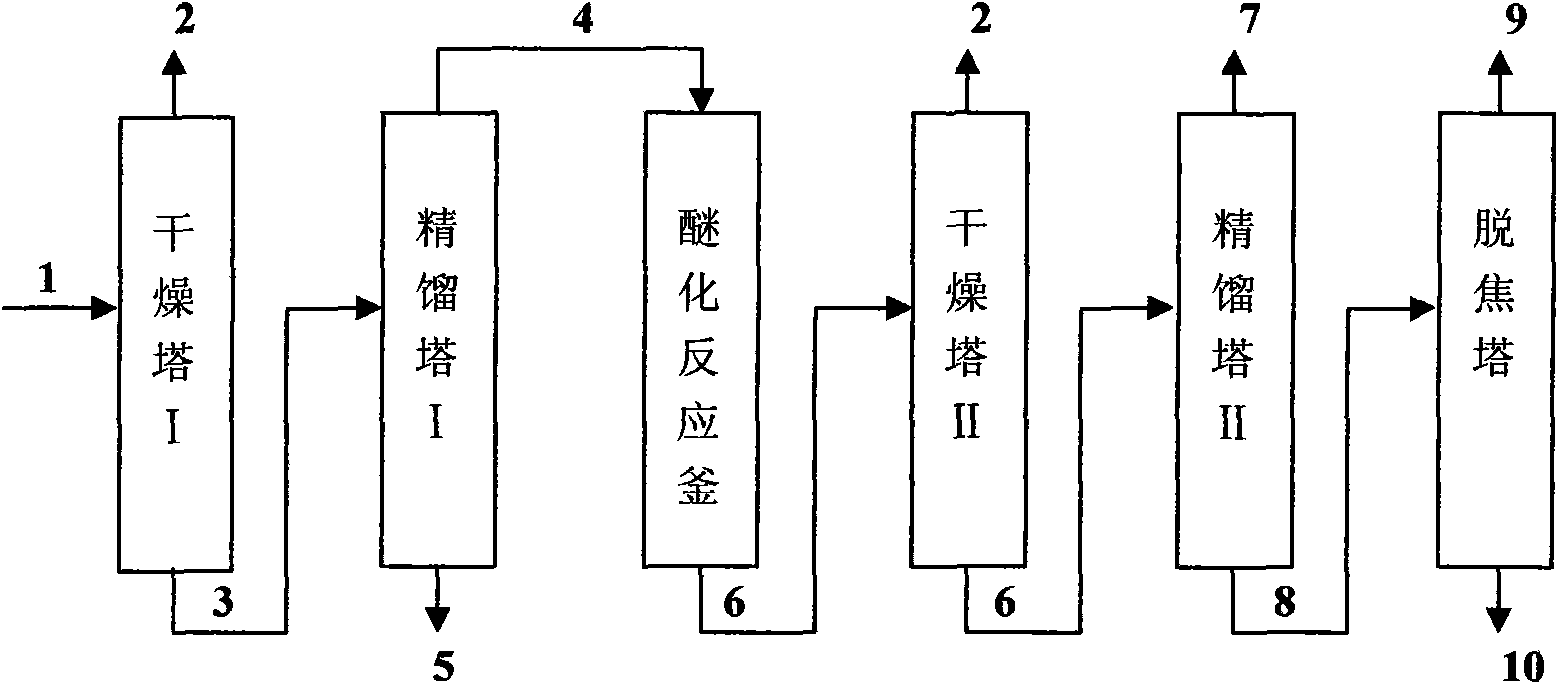

Method used

Image

Examples

Embodiment 1

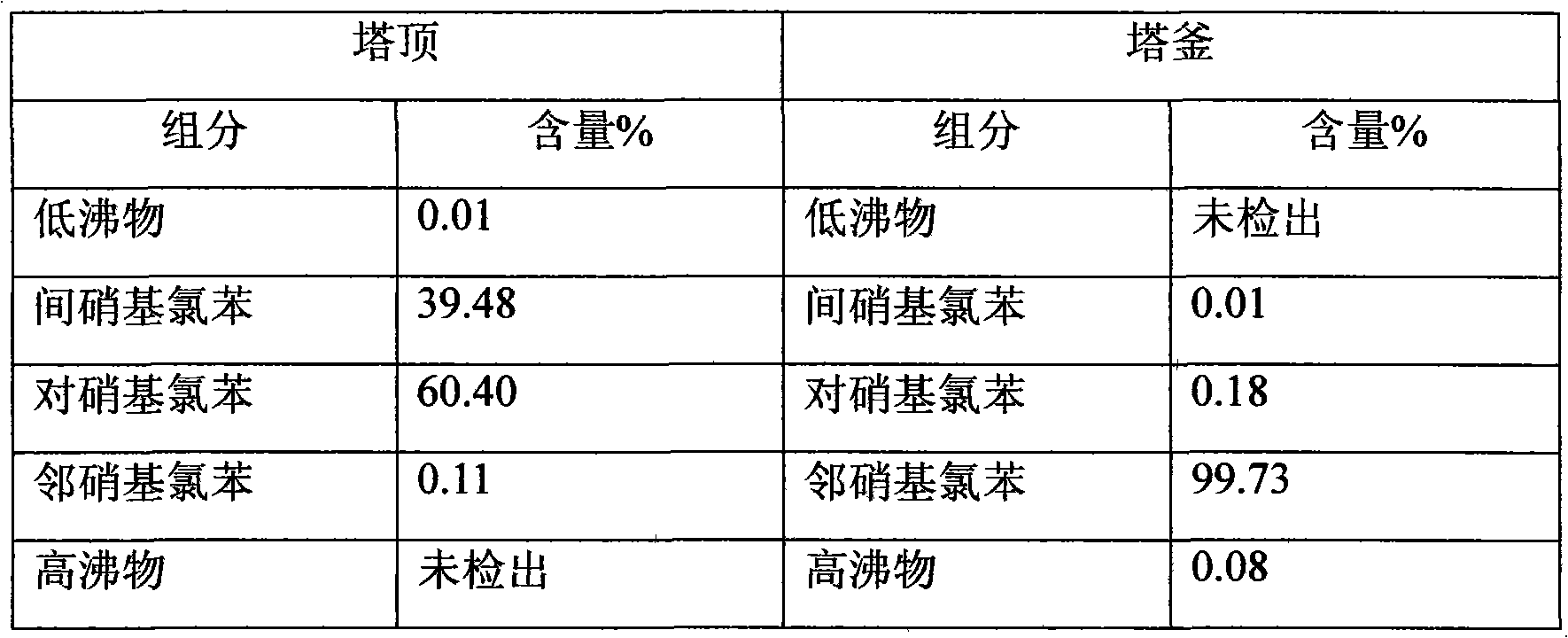

[0023] φ1400mm rectification tower, wire mesh corrugated packing, tower bottom temperature 172°C, tower top temperature 153°C, pressure 70mmHg, will contain m-nitrochlorobenzene 30.4%, p-nitrochlorobenzene 46.6%, o-nitrochlorobenzene 22.8% The nitrochlorobenzene meta-position oil is fed from the tower with a flow rate of 600kg / h, and the o-nitrochlorobenzene is extracted from the tower bottom with a flow rate of 460kg / h; Chlorobenzene-p-nitrochlorobenzene mixture, the composition of tower still and tower top is as follows with gas chromatography:

[0024]

Embodiment 2

[0026] 10m 3 Add 2200L of m-nitrochlorobenzene-p-nitrochlorobenzene mixture containing 39.5% of meta-position and 60.4% of para-position, and 2000L of methanol into the etherification reactor. 2800L of methanol solution with a concentration of 170.5g / L sodium hydroxide was added dropwise within the temperature range of 70°C to 90°C, and the addition time was 2 hours. Continue to heat up to 102°C and maintain for 4 hours. Rectify to remove excess methanol, wash and separate layers, and use gas chromatography to analyze the composition of the organic phase:

[0027] components

Embodiment 3

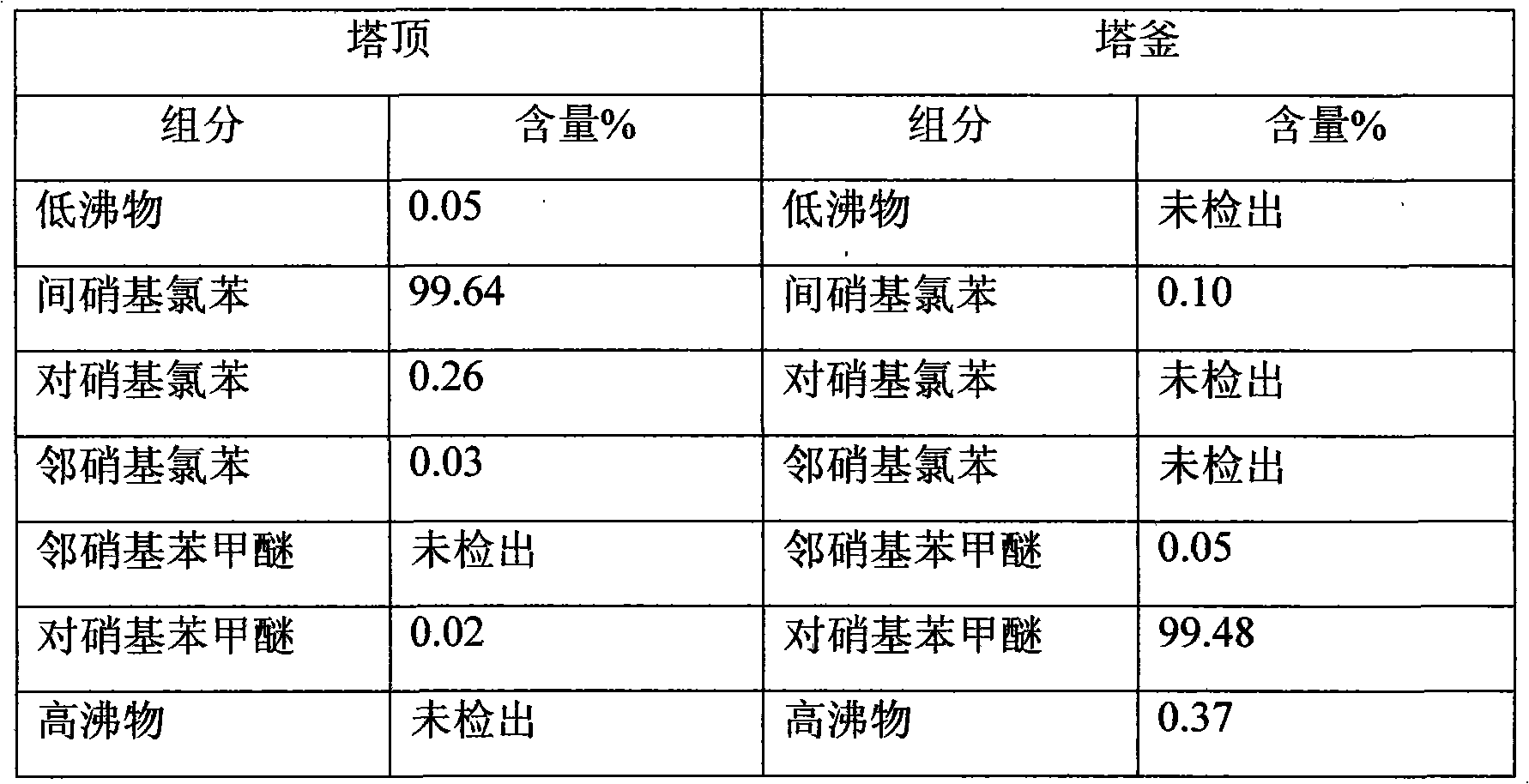

[0029] φ1200mm rectification tower, wire mesh corrugated packing, tower bottom temperature 200°C, tower top temperature 143°C, pressure 50mmHg, p-nitroanisole containing 59.2% p-nitroanisole and 40.1% m-nitrochlorobenzene -The m-nitrochlorobenzene mixture is fed from the tower with a flow rate of 500kg / h, and the p-nitroanisole crude product is extracted from the tower kettle with a flow rate of 300kg / h; Nitrochlorobenzene finished product, with gas chromatographic analysis tower still and tower top composition is as follows:

[0030]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com