Production method for combined forging and pressing oxygen lance nozzle and mould special for same

A production method and technology of oxygen lance nozzles, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve problems such as complex manufacturing process, difficulty in popularization and use, and potential safety hazards, and achieve Good processing performance, improved cooling effect, and improved water supply intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

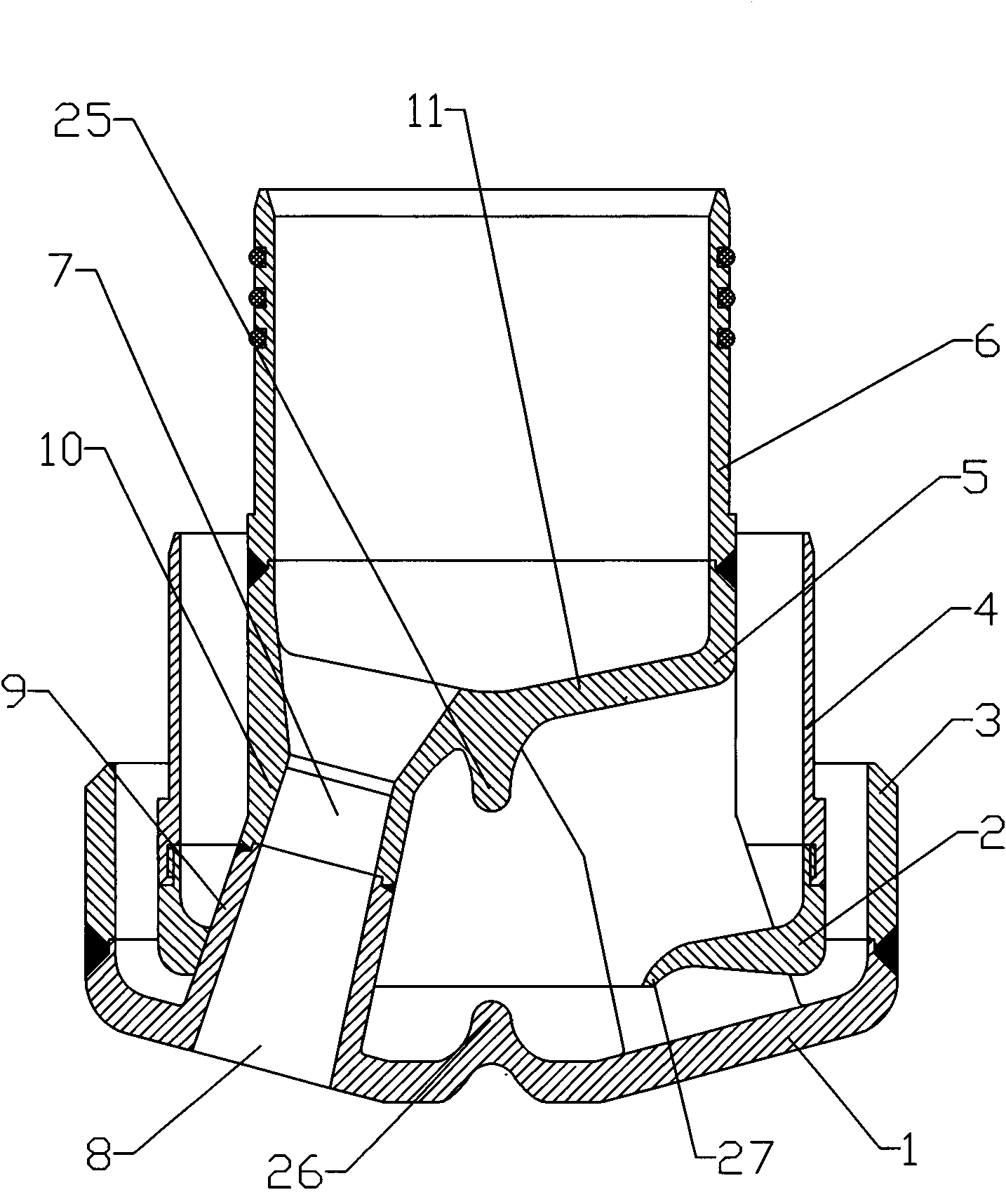

[0042] Examples such as Figure 2 to Figure 8 As shown, the production method of the combined forging oxygen lance nozzle includes the production method of the nozzle crown 1, the water retaining plate 2, the nozzle outer pipe 3, the nozzle middle pipe 4, the nozzle inner core 5 and the nozzle inner pipe 6, the nozzle crown 1 The production method comprises the following steps:

[0043] Material selection: select oxygen-free copper Tu1 with a purity of 99.97%;

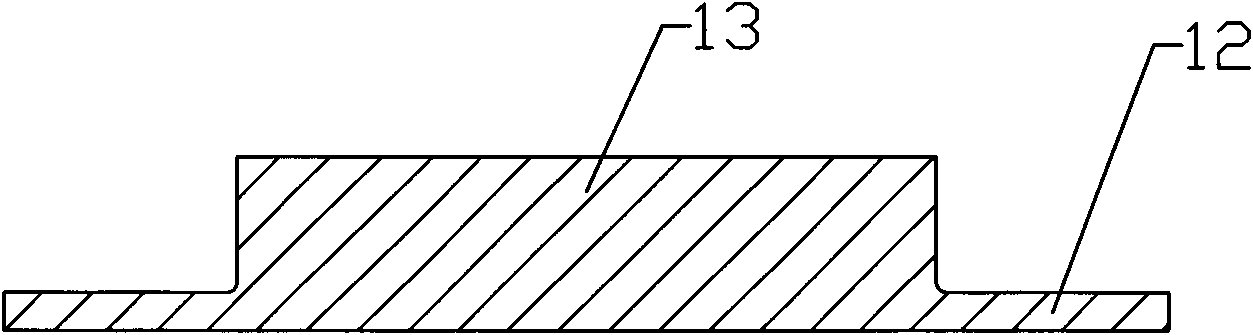

[0044] Forging blank: the selected oxygen-free copper Tu1 is forged into a blank. The blank includes a base 12 and a disc 13 with an integrated structure. The base 12 is larger in diameter than the disc 13. After forging, the metallographic structure of the copper is a twin crystal α phase, resulting in high density;

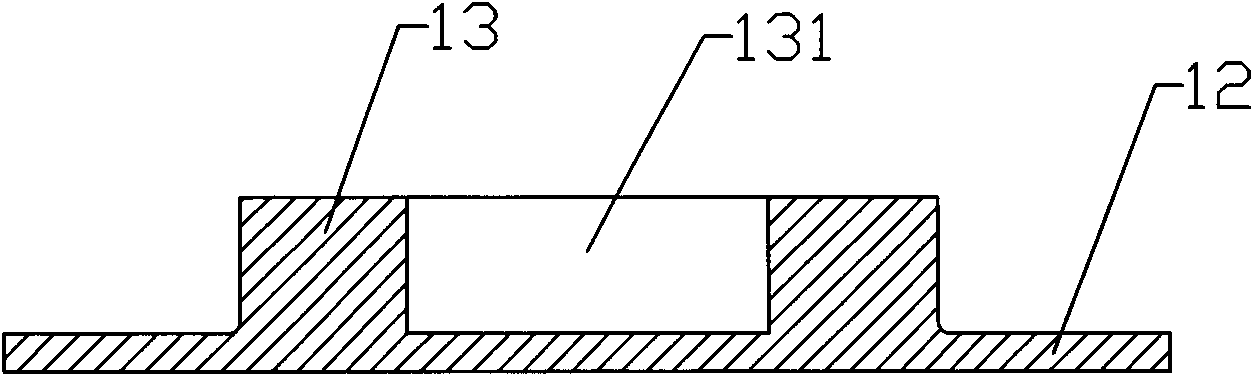

[0045] Intermediate billet production: draw a line on the disk 13 and perform volume distribution, that is, determine the position of the column 14, first process the inner cavity 131 on the disk 13, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com