IGCT (Integrated Gate Commutated Thyristor) frequency testing method and device

A test device and frequency characteristic test technology, applied in the field of IGCT frequency test method and device, can solve the problems of high cost and high complexity, and achieve the effect of low cost, strong adaptability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

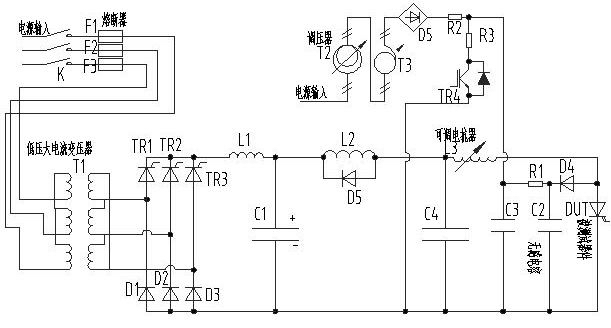

[0020] A device for IGCT frequency test proposed according to the above test method is: an IGCT frequency test device, including a low-voltage high-current phase-controlled rectifier circuit composed of a thyristor and a rectifier; a reactor for improving harmonics and current impact , and the main capacitor; the load reactor and its freewheeling diode; the adjustable reactor (or a group of reactors for combination) to simulate the turn-off overvoltage; the clamping circuit of the IGCT and the power supply for adjusting the clamping voltage, and A voltage regulation system to change the voltage of the clamp circuit and a chopper system to stabilize the voltage. The clamping circuit includes a clamping diode, a clamping capacitor, a clamping resistor, an adjustable voltage source connected to the clamping resistor, and a chopper for stabilizing the voltage source.

[0021] Such as figure 1 As shown, the described low-voltage high-current phase-controlled rectification circuit...

Embodiment 2

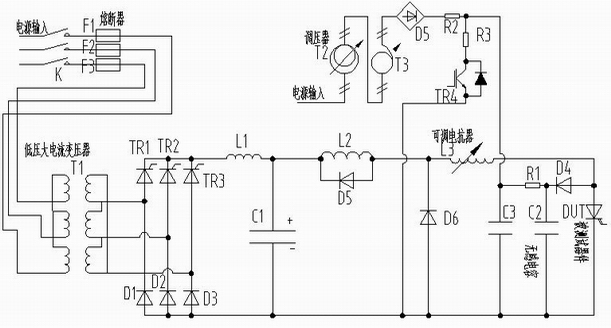

[0025] As another embodiment of the present invention, the figure 1 Replace C4 in the diode D6, such as figure 2 , then L3 forms a loop through D4, C2, and D6 to realize figure 1 The same function as the corresponding part in .

Embodiment 3

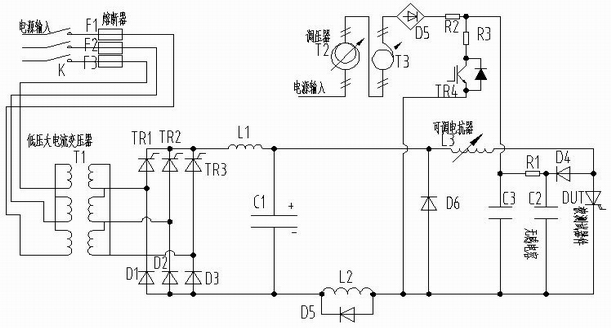

[0027] Of course you can also put figure 1 in L2 and D5 placed as in image 3 The functions of L2 and D5 are basically similar.

[0028] The characteristic of this frequency test device is that it adopts low voltage and high current, cooperates with adjustable clamping voltage to simulate the real working condition, and tests the frequency characteristics of IGCT. The device has low total power, low cost and strong adaptability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com