Method for preparing multilayer hollow metal microspheres for electromagnetic wave absorbing material

A technology of hollow metal microspheres and absorbing materials, applied in the direction of electrical components, magnetic field/electric field shielding, etc., can solve the problem of Fe or Co hollow microspheres not being successful, and achieve the effect of reducing the thickness of the wave-absorbing layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

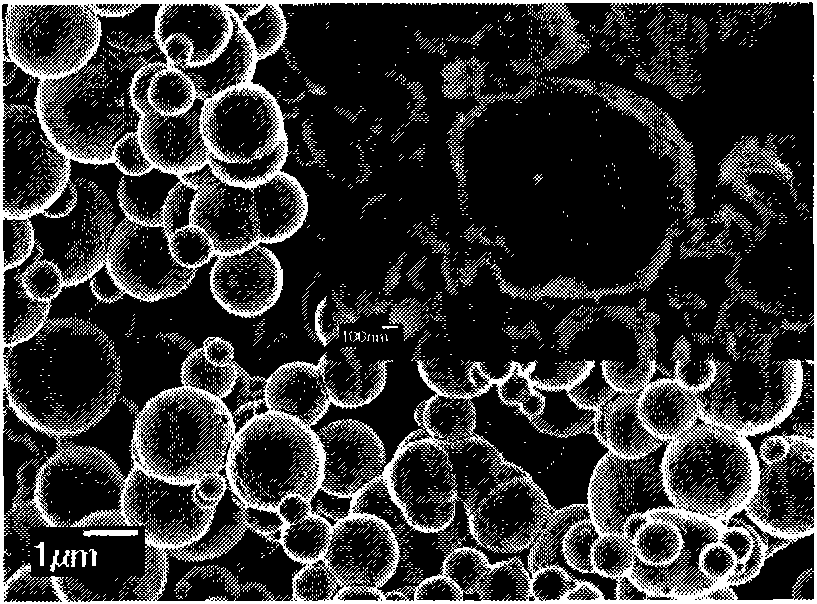

[0048] Example 1 Ni-Co 1-x Fe x , x=0.1 double-layer hollow microsphere

[0049] The synthesis of hollow Ni spheres adopts an autocatalytic reduction process, and nickel sulfate and sodium hydroxide solution are used as starting materials to obtain [Ni(OH) 2 ]colloid. Ni hollow spheres can be synthesized by mixing sodium hypophosphite solution and colloid. The detailed process is as follows:

[0050] 20 g NiSO 4 ·7H 2 O and 24.2 g NaH 2 PO 2 2H 2 O were dissolved in 200 ml distilled water respectively. The solution was heated at 90°C for 30 minutes, then the nickel sulfate solution and the sodium hydroxide solution were mixed, NiSO 4 The molar ratio with NaOH is 1:1, stir to obtain light green colloidal Ni(OH) 2 solution. NaH 2 PO 2 Add Ni(OH) to the solution 2 solution, stirred, and reacted for 5 minutes to obtain gray-black powder. The powder was rinsed several times with distilled water, then heated to 90°C with an electric hot plate and dried for 1 hour.

...

Embodiment 2

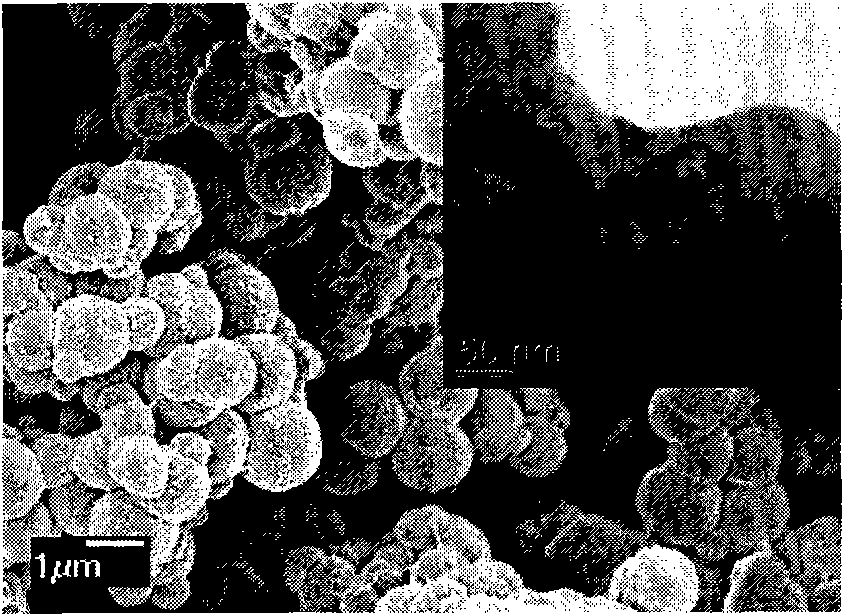

[0053] Example 2 Ni-Co 1-x Fe x (x=0.2) double-layer hollow microspheres

[0054] The synthesis of hollow Ni spheres adopts an autocatalytic reduction process, and nickel sulfate and sodium hydroxide solution are used as starting materials to obtain [Ni(OH) 2 ]colloid. Ni hollow spheres can be synthesized by mixing sodium hypophosphite solution and colloid. The detailed process is as follows:

[0055] 20 g NiSO 4 ·7H 2 O and 24.2 g NaH 2 PO 2 2H 2 O were dissolved in 200 ml distilled water respectively. The solution was heated at 90°C for 30 minutes, then the nickel sulfate solution and the sodium hydroxide solution were mixed, NiSO 4 The molar ratio with NaOH is 1:1, stir to obtain light green colloidal Ni(OH) 2 solution. NaH 2 PO 2 Add Ni(OH) to the solution 2 solution, stirred, and reacted for 5 minutes to obtain gray-black powder. The powder was rinsed with distilled water, and then heated to 90°C with an electric hot plate and dried for 1 hour.

[0056] C...

Embodiment 3

[0058] Example 3 Ni-Co 1-x Fe x (x=0) hollow microsphere

[0059]The synthesis of hollow Ni spheres adopts an autocatalytic reduction process, and nickel sulfate and sodium hydroxide solution are used as starting materials to obtain [Ni(OH) 2 ]colloid. Ni hollow spheres can be synthesized by mixing sodium hypophosphite solution and colloid. The detailed process is as follows:

[0060] 20 g NiSO 4 ·7H 2 O and 24.2 g NaH 2 PO 2 2H 2 O were dissolved in 200 ml distilled water respectively. The solution was heated at 90°C for 30 minutes, then the nickel sulfate solution and the sodium hydroxide solution were mixed, NiSO 4 The molar ratio with NaOH is 1:1, stir to obtain light green colloidal Ni(OH) 2 solution. NaH 2 PO 2 Add Ni(OH) to the solution 2 solution, stirred, and reacted for 5 minutes to obtain gray-black powder. The powder was rinsed with distilled water, then heated to 90°C with an electric hot plate and dried for 1 hour.

[0061] Co thin film coatings ...

PUM

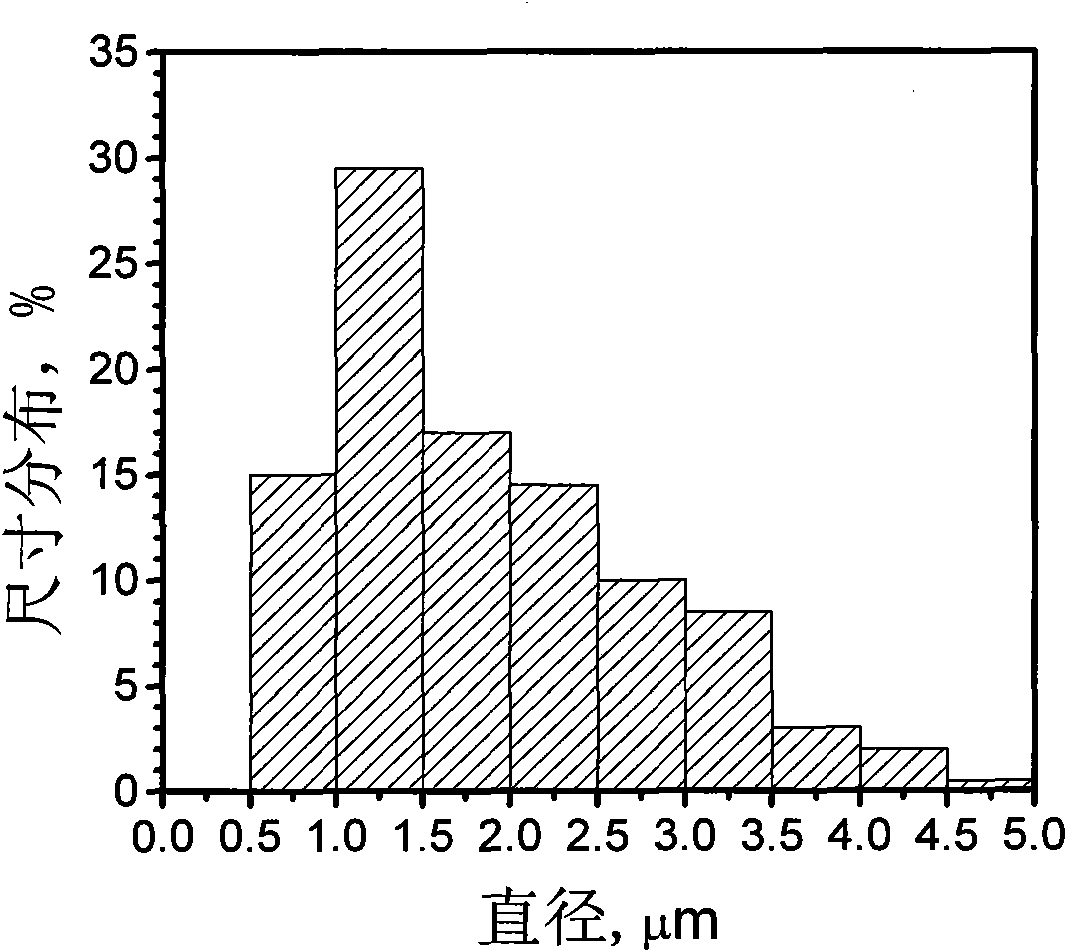

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com