Method for synthesizing molecular sieve by modified kaolin

A kaolin and molecular sieve technology, which is applied in the directions of favhedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of poor flexibility in component modulation, high price of ultra-fine soil, high raw material requirements, etc. The effect of reaction contact opportunity, concentrated pore size distribution, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

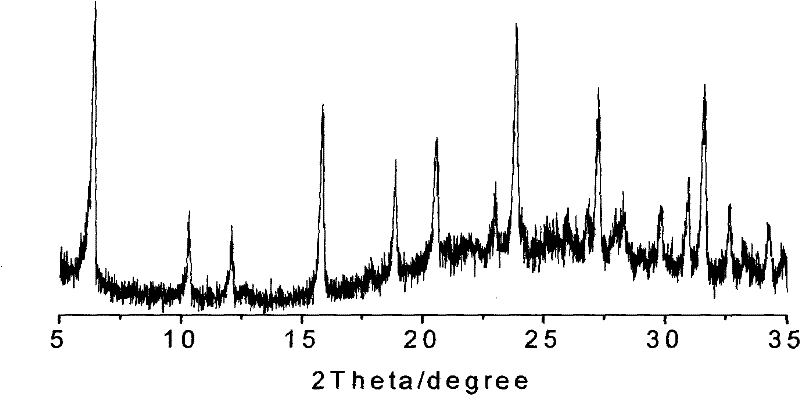

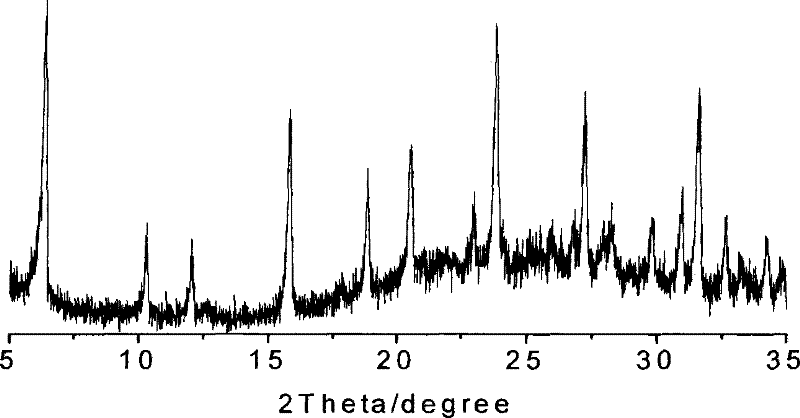

Image

Examples

Embodiment approach 1

[0021] Roast 500g of Suzhou kaolin at 450°C for 3 hours, weigh 60.0g of the calcined kaolin and react with 120.0ml of mixed acid solution, the mixed acid solution is prepared with 20.0ml of 37wt% hydrochloric acid and 3.4ml of 98wt% concentrated sulfuric acid, the reaction temperature is 100°C, the reaction time for 26 hours, filtered, washed with deionized water until no acid groups were present, dried, and then calcined at 850° C. for 2 hours to obtain secondary partial earth 1.

Embodiment approach 2

[0023] Roast 500g of Suzhou kaolin at 550°C for 2 hours, weigh 60.0g of the calcined kaolin and react with 120.0ml of hydrochloric acid solution, prepare the salt solution with 30.0ml of 37wt% hydrochloric acid, react at 100°C for 26 hours, filter, and wash with deionized water until there are no acid radicals, dried, and then calcined at 850°C for 2 hours to obtain secondary partial soil 2.

Embodiment approach 3

[0025] Roast 500g Suzhou kaolin at 550°C for 2 hours, weigh 60.0g of the calcined kaolin and react with 120.0ml sulfuric acid solution, the sulfuric acid solution is prepared with 4.0ml 98wt% concentrated sulfuric acid, react at 100°C for 24 hours, filter, and wash with deionized water until there is no acid group, dried, and then calcined at 830°C for 2 hours to obtain secondary partial soil 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com