Phosphate red fluorescent powder for light-emitting diode and preparation method thereof

A technology of light-emitting diodes and red phosphors, applied in the field of materials, can solve the uninvolved and other problems, and achieve the effects of easy operation, simple preparation method and good color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Raw material is CaCO 3 (analytical pure), NaHCO 3 (analytical pure), (NH 4 ) 2 HPO 4 (analytical pure) and Eu 2 o 3 (99.99%), the molar ratio between them is 0.95:1:1:0.025, the raw materials are accurately weighed and mixed and ground evenly, placed in a crucible, placed in a high-temperature furnace at 900 ° C for 4 hours, and naturally cooled to room temperature and grind finely to obtain a red phosphor NaCa 0.95 PO 4 :0.05Eu 3+ .

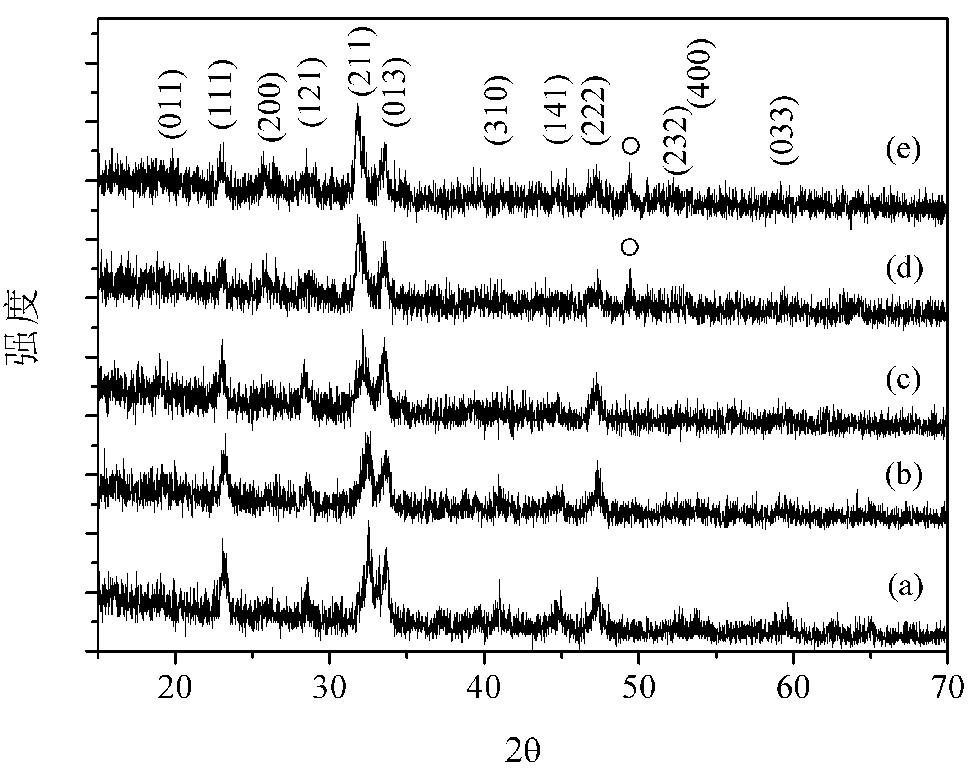

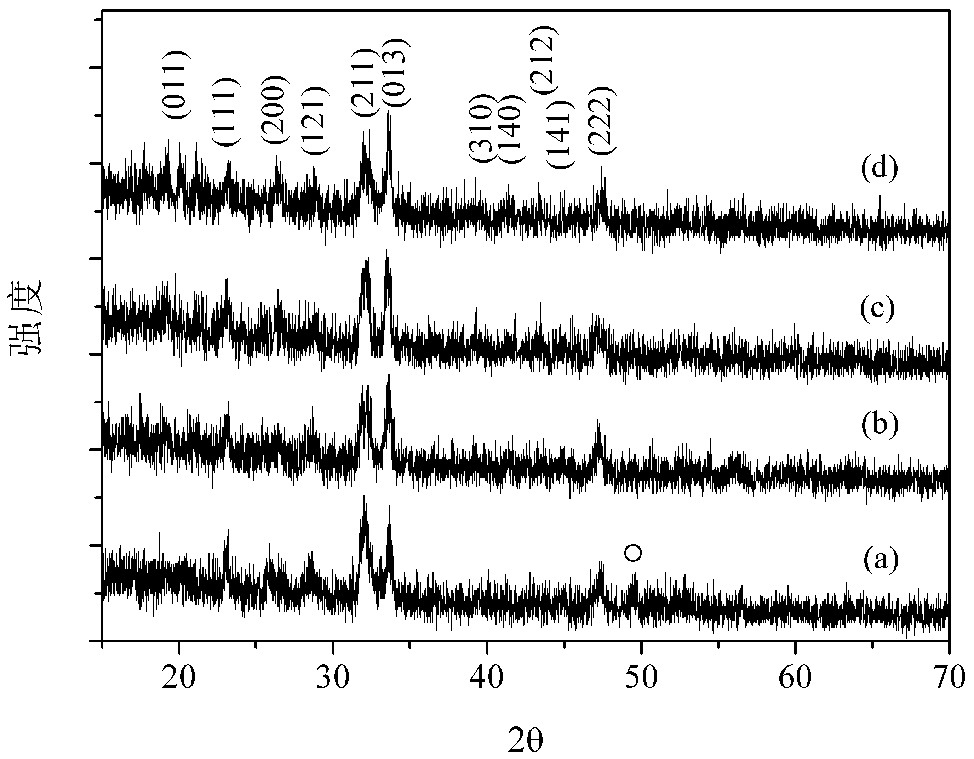

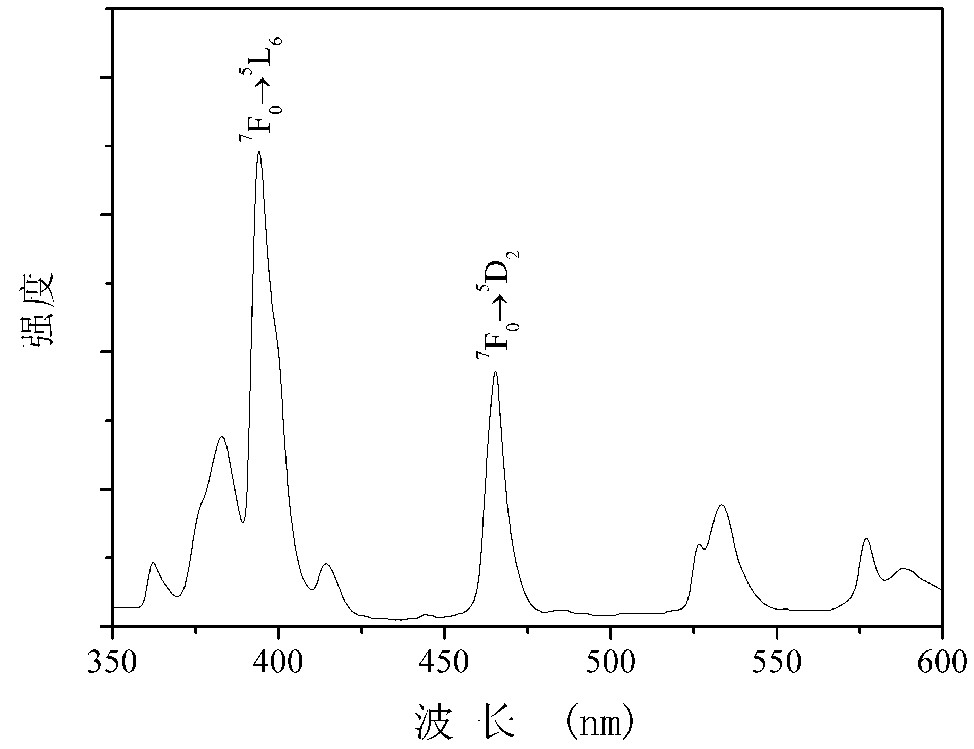

[0026] The X-ray diffraction pattern of the red phosphor powder used for the light-emitting diode obtained is shown in the appendix figure 1 (a), the position of each diffraction peak is in good agreement with the standard card JCPDS29-1193, which belongs to NaCaPO 4 Single phase; its excitation spectrum when monitored at 619 nm has strong excitation peaks near 395 nm and 465 nm, which match well with the emission wavelengths of near-ultraviolet and blue LED chips respectively; its excitation at 395 nm or 465 nm , the maximum e...

Embodiment 2

[0028] Raw material is CaCO3 (analytical pure), NaHCO 3 (analytical pure), (NH 4 ) 2 HPO 4 (analytical pure) and Eu 2 o 3 (99.99%), the molar ratio between them is 0.85:1:1:0.075, accurately weigh each raw material and mix and grind evenly, put it in a crucible, put it in a high-temperature furnace at 900 ℃ for 4 hours, and cool naturally to room temperature and grind finely to obtain a red phosphor NaCa 0.85 PO 4 :0.15Eu 3+ .

[0029] The X-ray diffraction pattern of the red phosphor powder used for the light-emitting diode obtained is shown in the appendix figure 1 (b), the position of each diffraction peak is in good agreement with the standard card JCPDS29-1193, which belongs to NaCaPO 4 Single phase; its excitation spectrum when monitored at 619 nm has strong excitation peaks near 395 nm and 465 nm, which match well with the emission wavelengths of near-ultraviolet and blue LED chips respectively; its excitation at 395 nm or 465 nm , the maximum emission wavelen...

Embodiment 3

[0031] Raw material is CaCO 3 (analytical pure), NaHCO 3 (analytical pure), (NH 4 ) 2 HPO 4 (analytical pure) and Eu 2 o 3 (99.99%), the molar ratio between them is 0.8:1:1:0.1, accurately weigh each raw material and mix and grind evenly, put it in a crucible, put it in a high-temperature furnace at 900 ℃ for 4 hours, and cool naturally to room temperature and grind finely to obtain a red phosphor NaCa 0.8 PO 4 :0.2Eu 3+ .

[0032] The X-ray diffraction pattern of the red phosphor powder used for the light-emitting diode obtained is shown in the appendix figure 1 (c), the position of each diffraction peak is in good agreement with the standard card JCPDS29-1193, which belongs to NaCaPO 4 Single phase; its excitation spectrum when monitored at 619 nm has strong excitation peaks near 395 nm and 465 nm, which match well with the emission wavelengths of near-ultraviolet and blue LED chips respectively; its excitation at 395 nm or 465 nm , the maximum emission wavelength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com