White long-lasting luminescent material and synthetic method thereof

A technology of long afterglow luminescence and synthesis method, which is applied to luminescent materials, chemical instruments and methods, etc., can solve the problems of prolonging afterglow time and not realizing white emission, etc., and achieves the effects of low production cost, easy realization, and short constant temperature time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

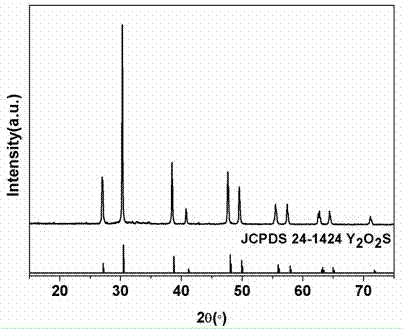

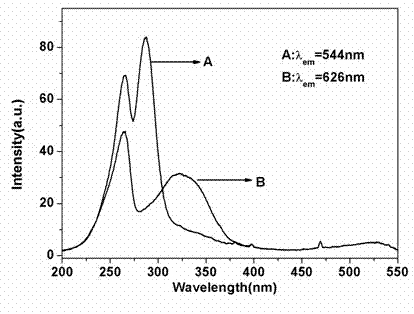

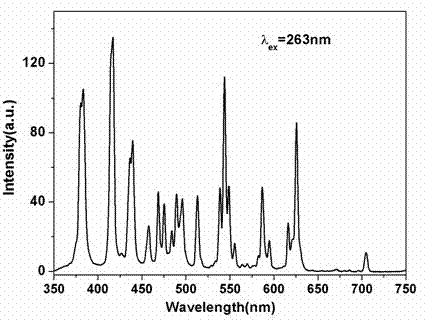

[0032] Put the raw materials of yttrium oxide, europium oxide, terbium oxide, anhydrous sodium carbonate, basic magnesium carbonate, and silicon dioxide into an electric blast drying oven, dry at 60°C for 6 hours, and then change the stoichiometric ratio to Y 2 o 2 S: 0.003Tb 3+ , 0.0015Eu 3+ , 0.06Mg 2+ , 0.06Si 4+ Take by weighing 4.5213g yttrium oxide, 0.0053g europium oxide, 0.0112g terbium oxide, 1.4231g anhydrous sodium carbonate, 0.5380g potassium phosphate, 0.0734g silicon dioxide, 0.1221g basic magnesium carbonate, 1.2760g sublimated sulfur, and Put it into a glass mortar and grind for 3h, and mix well. Put the uniformly mixed raw materials into an alumina crucible, keep the temperature at 1000°C for 30 minutes in a reducing atmosphere, and then naturally cool to room temperature with the furnace to obtain Y 2 o 2 S: 0.003Tb 3+ , 0.0015Eu 3+ , 0.06Mg 2+ , 0.06Si 4+ White long afterglow luminescent material. The sample test is as follows: 1. Determine th...

Embodiment approach 2

[0034] Put the raw materials of yttrium oxide, europium oxide, terbium oxide, anhydrous sodium carbonate, basic magnesium carbonate, and silicon dioxide into an electric blast drying oven, dry at 60°C for 6 hours, and then change the stoichiometric ratio to Y 2 o 2 S: 0.003Tb 3+ , 0.0015Eu 3+ , 0.04Mg 2+ , 0.04Si 4+ Take by weighing 4.5213g yttrium oxide, 0.0053g europium oxide, 0.0112g terbium oxide, 1.4231g anhydrous sodium carbonate, 0.5380g potassium phosphate, 0.0489g silicon dioxide, 0.0914g basic magnesium carbonate, 1.2760g sublimated sulfur, and It was put into a glass mortar, manually ground for 3 hours, and mixed evenly. Put the uniformly mixed raw materials into an alumina crucible, keep the temperature at 1000°C for 30 minutes in a reducing atmosphere, and then naturally cool to room temperature with the furnace to obtain Y 2 o 2 S: 0.003Tb 3+ , 0.0015Eu 3+ , 0.04Mg 2+ , 0.04Si 4+ White long afterglow luminescent material. The sample test is as follows...

Embodiment approach 3

[0036] Put the raw materials of yttrium oxide, europium oxide, terbium oxide, anhydrous sodium carbonate, basic magnesium carbonate, and silicon dioxide into an electric blast drying oven, dry at 60°C for 6 hours, and then change the stoichiometric ratio to Y 2 o 2 S: 0.003Tb 3+ , 0.0015Eu 3+ , 0.1Mg 2+ , 0.1Si 4+ Take by weighing 4.5213g yttrium oxide, 0.0053g europium oxide, 0.0112g terbium oxide, 1.4231g anhydrous sodium carbonate, 0.5380g potassium phosphate, 0.1223g silicon dioxide, 0.2036g basic magnesium carbonate, 1.2760g sublimated sulfur, and It was put into a glass mortar, manually ground for 3 hours, and mixed evenly. Put the uniformly mixed raw materials into an alumina crucible, keep the temperature at 1000°C for 30 minutes in a reducing atmosphere, and then naturally cool to room temperature with the furnace to obtain Y 2 o 2 S: 0.003Tb 3+ , 0.0015Eu 3+ , 0.04Mg 2+ , 0.04Si 4+ White long afterglow luminescent material. The sample test is as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com