Method for growing yttrium ferrite crystal by guided mold pulling method

The technology of pulling method and yttrium ferrite is applied in the field of growing yttrium ferrite crystal by guided mode pulling method. The effect of uniform distribution of processes and components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0044] (1) Synthesis of polycrystalline raw materials: Accurately weigh Fe with a purity of 99.99% according to the ratio of Y / (Y+Fe) to 40.0% 2 o 3 and Y 2 o 3 Drugs, put the weighed drugs into a corundum mortar and grind them evenly, then press them into tablets on a tablet press, and then perform high-temperature sintering at a temperature of 1200°C for 15 hours to prepare polycrystalline raw materials.

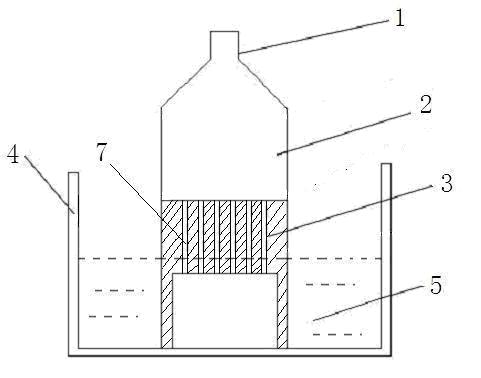

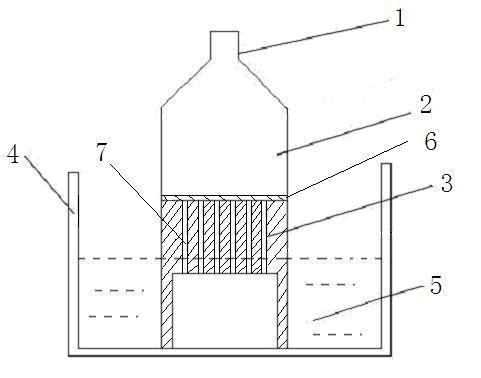

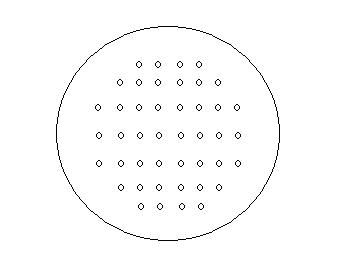

[0045] (2) Single crystal growth: Using the guided mold pulling method, the iridium crucible is used as the crystal growth container, the guided mold is installed in the center of the crucible, and a circular iridium sheet with holes is placed on the upper surface of the guided mold. Add the prepared polycrystalline raw material in the crucible again, heat the crucible under nitrogen atmosphere to melt the polycrystalline raw material into a molten body, and make the molten body 5 of the polycrystalline raw material not pass through the gap in the lower part of the guide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com