Method for detecting polydimethylsiloxane

The technology of polydimethylsiloxane and dimethylsiloxane is applied in the detection field of polydimethylsiloxane, which can solve the problems of difficulty in quantitative analysis of polydimethylsiloxane and the like, and achieves an obvious social Benefit and economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

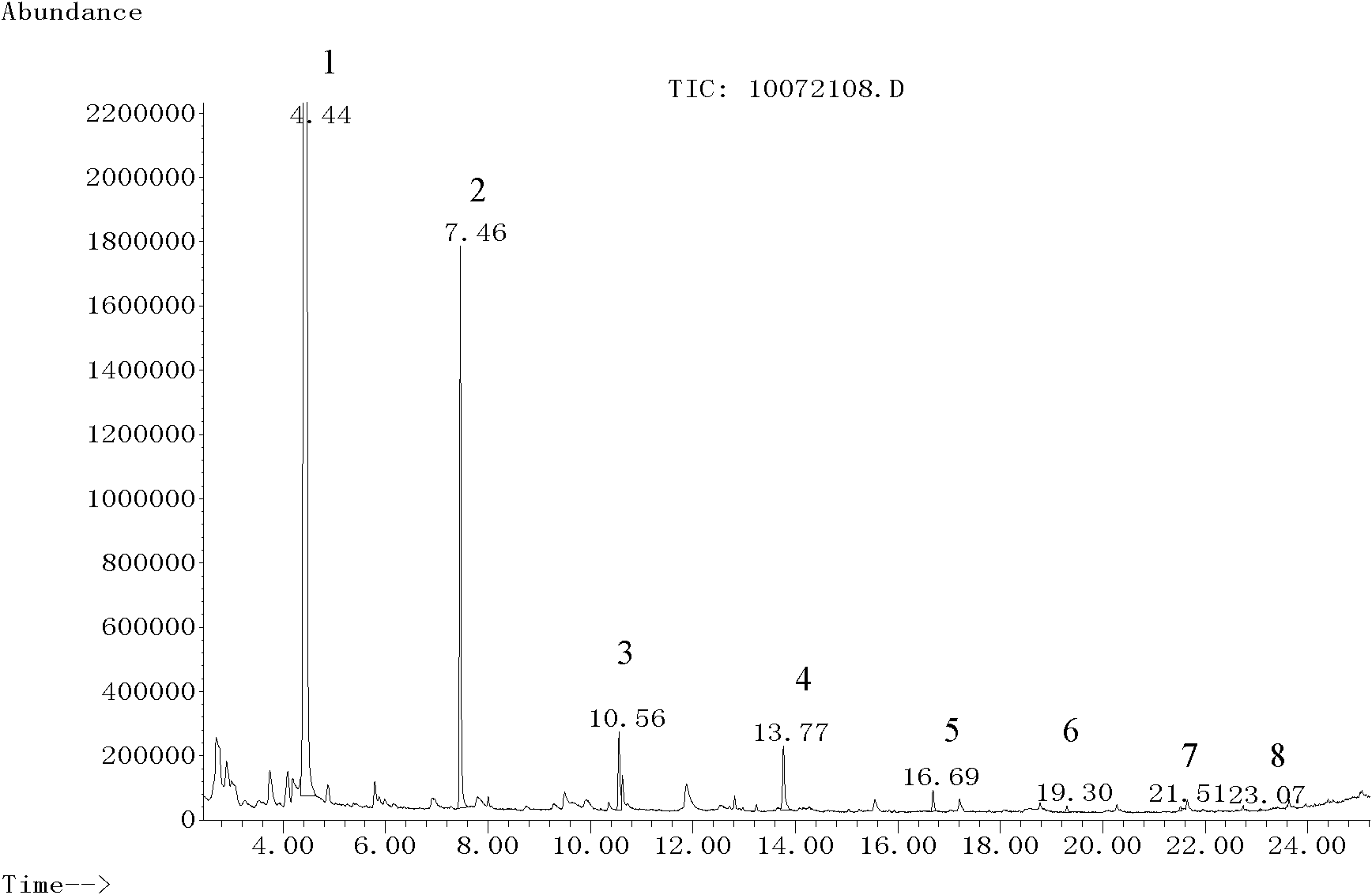

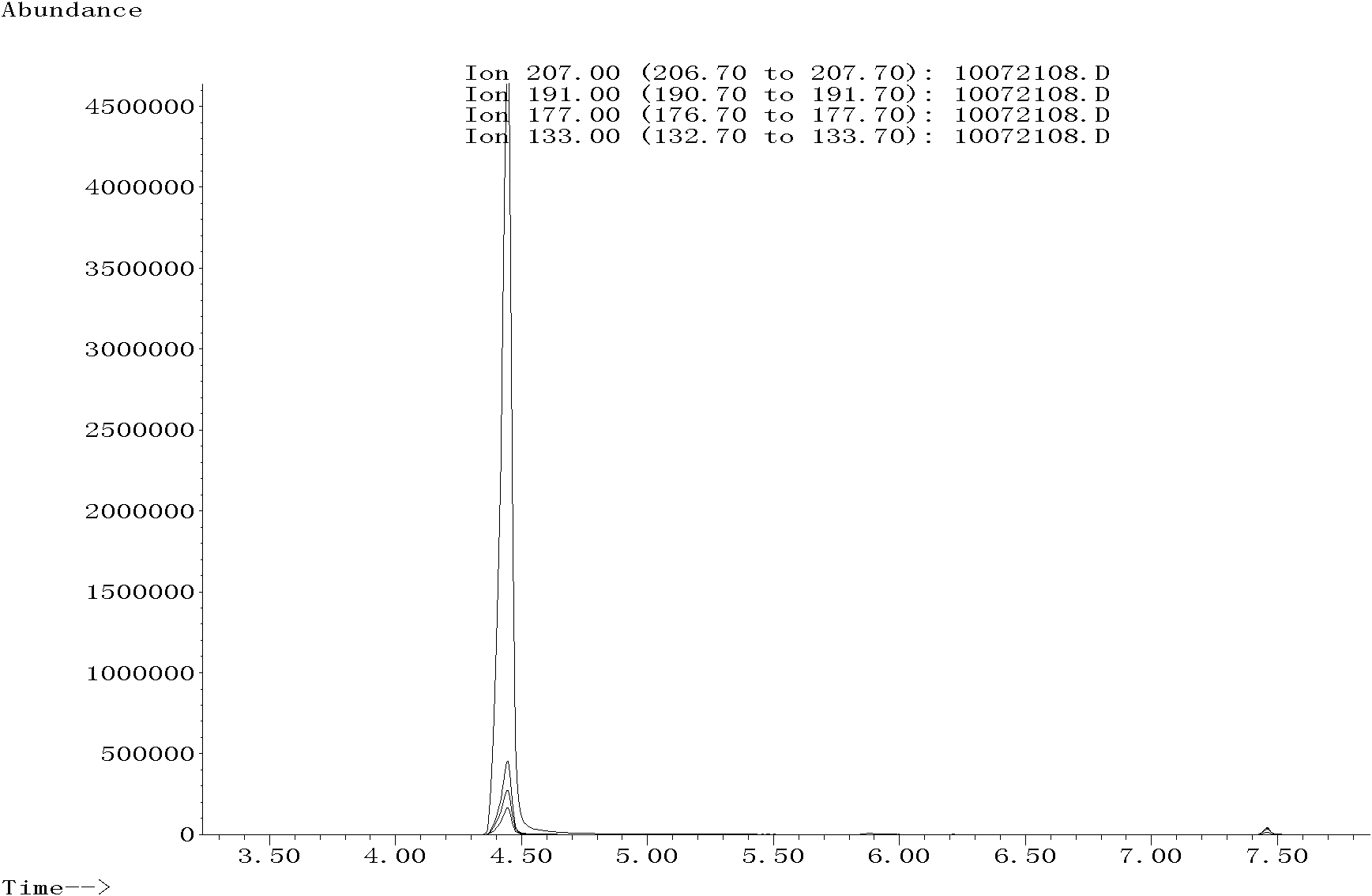

[0034] Embodiment 1: the mensuration of polydimethylsiloxane in fried chicken

[0035] (1) Weigh 10.0g of fried chicken sample, put it in a blender and crush it, use petroleum ether-ethyl acetate (volume ratio 5:1) 50mL, extract by ultrasonic vibration for 3 times, combine the 3 extracts, concentrate and pass Silica gel small column, discard the effluent, rinse with 10mL petroleum ether, discard the eluent to remove grease, then elute with 20mL petroleum ether-ethyl acetate (volume ratio 5:1), collect the eluent, Concentrate to 1.0mL.

[0036] (2) Preparation of standard solution: Accurately weigh 100mg (accurate to 0.1mg) of each polydimethylsiloxane standard product, dissolve it in ethyl acetate in a 100mL volumetric flask and make it to volume. The concentration of the solution is 1g / L , stored in a refrigerator at 4°C, valid for 6 months; standard working solution: absorb the standard stock solution, dilute it step by step with ethyl acetate to obtain 10, 25, 50, 100, 200...

Embodiment 2

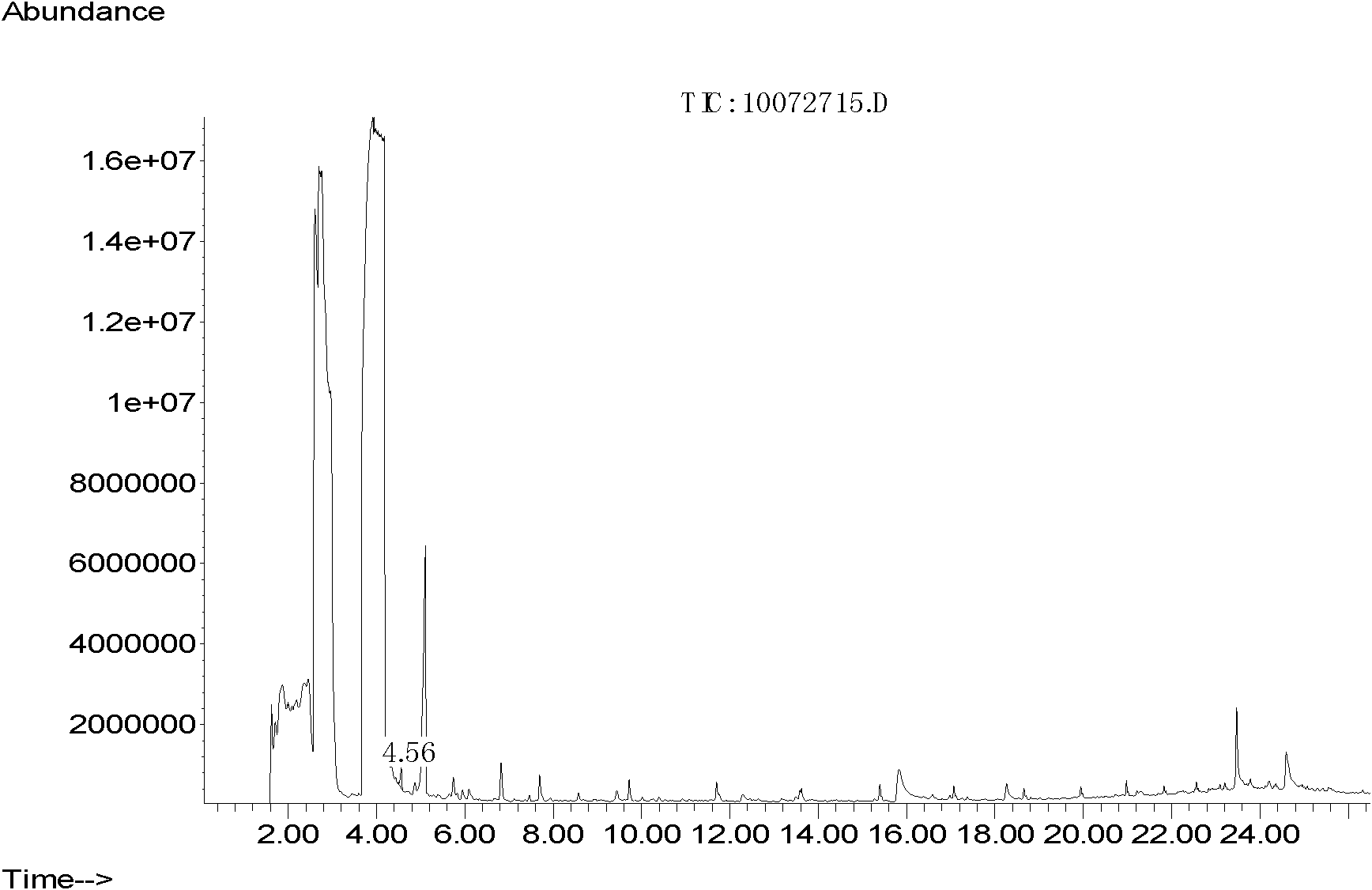

[0044] Embodiment 2: the mensuration of polydimethylsiloxane in apple peel

[0045] (1) Take the apple peel, chop it, weigh 5.0g sample, use 25mL of petroleum ether-ethyl acetate (volume ratio 5:1), extract by ultrasonic vibration for 3 times, combine the 3 extracts, concentrate and pass through silica gel Column, discard the effluent, and then elute with 20mL petroleum ether-ethyl acetate (5:1), collect the eluate, concentrate and dilute to 1.0mL.

[0046] (2) Preparation of standard solution: Accurately weigh 100mg (accurate to 0.1mg) of each polydimethylsiloxane standard product, dissolve it in ethyl acetate in a 100mL volumetric flask and make it to volume. The concentration of the solution is 1g / L , stored in a refrigerator at 4°C, valid for 6 months; standard working solution: absorb the standard stock solution, dilute it step by step with ethyl acetate to obtain 10, 25, 50, 100, 200, 500mg of polydimethylsiloxane / L series of standard solutions.

[0047] Take 10 μL ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com