Process for the production of gamma-aminobutyric acid

A technology for aminobutyric acid and amino acids, which is applied in the field of producing γ-aminobutyric acid, and can solve problems such as unrecorded suitable methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0046] 3.1 Dysregulation of other genes

[0047] Fermentative production of GABA using recombinant Corynebacterium glutamate producers expressing glutamate decarboxylase can be further improved if combined with dysregulation of at least one other gene as listed below.

[0048]

[0049] A preferred form of "amplified" is an "up" mutation that increases gene activity, for example gene amplification by using a strong expression signal and / or point mutations that increase enzymatic activity.

[0050] A preferred form of "attenuation" is a "down" mutation that reduces gene activity, eg gene deletion or dysregulation by using weak expression signals and / or point mutations that disrupt or reduce enzyme activity.

[0051] 3.2 Proteins of the invention

[0052] The invention is not limited to the specifically mentioned proteins, but also extends to functional equivalents thereof.

[0053] Within the scope of the present invention, "functional equivalents" or "analogues" or "functi...

Embodiment 1

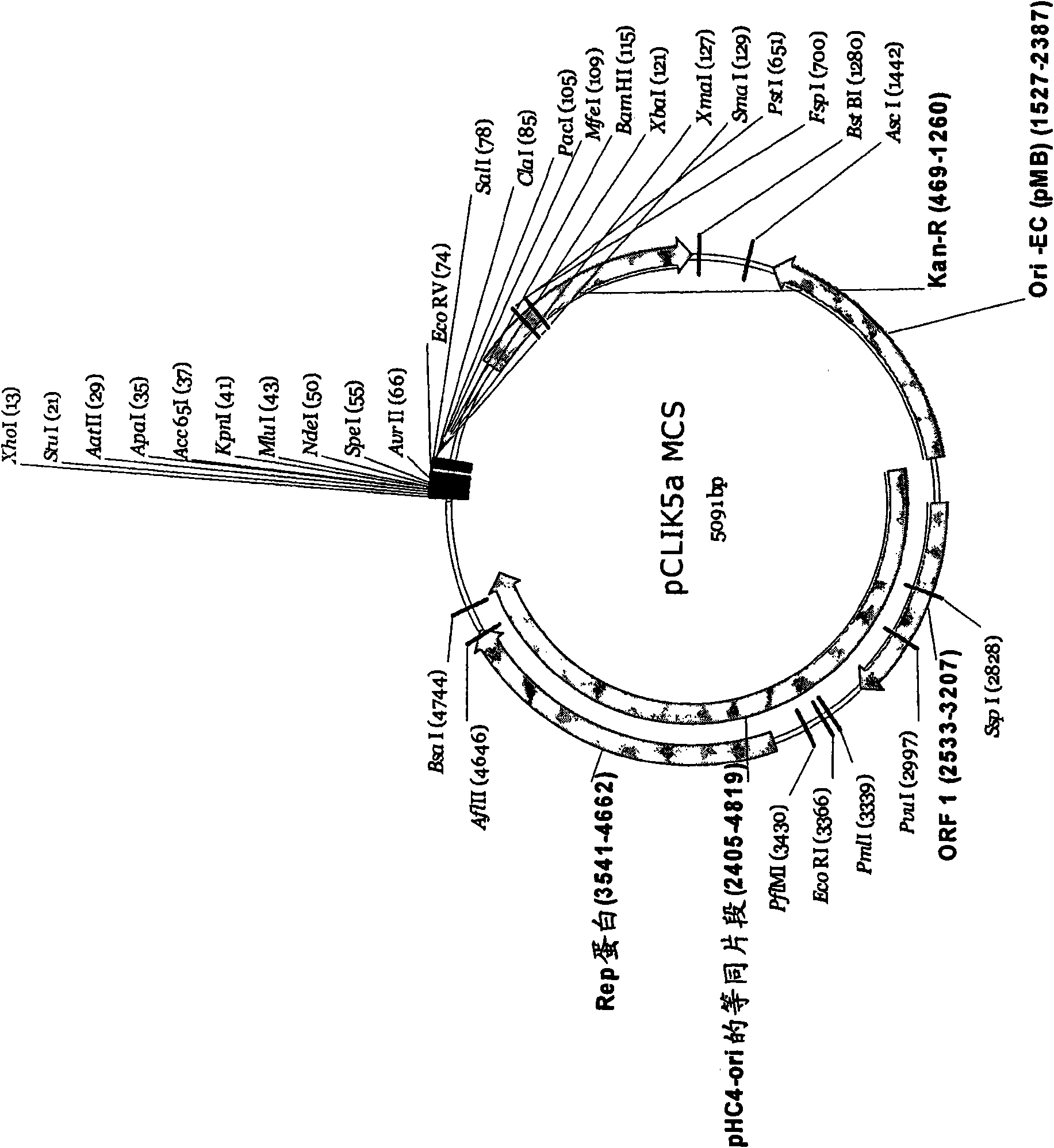

[0209] Example 1: Cloning of the Escherichia coli glutamic acid decarboxylase (GAD) gene

[0210] PCR primers WKJ95 / WKJ96 and WKJ99 / WKJ100 were used to amplify the DNA fragments containing gadBC and gadA genes, respectively, using the chromosomal DNA of Escherichia coli as a template. The amplified DNA fragment was purified, digested with restriction enzymes XhoI / XbaI (for gadBC) and XhoI / SpeI (for gadA), and ligated into pClik5aMCS (SEQ ID NO: 14; image 3 ) vectors to obtain pClik5aMCSgadBC and pClik5aMCSgadA respectively.

[0211] Oligonucleotide primers used:

[0212] WKJ95 ccgctcgagcggcccaagcttcggtaaatacttataccggag (SEQ ID NO: 10)

[0213] WKJ96 ctagtctagactagcccaagcttgtcgatcatcgcctgttg (SEQ ID NO: 11)

[0214] WKJ99 ccgctcgagcggcccaagcttcgtgataaattgcgtcagaaag (SEQ ID NO: 12)

[0215] WKJ100 ctagactagtctagcccaagcttctcgaatttggcttgcatcc (SEQ ID NO: 13)

Embodiment 2

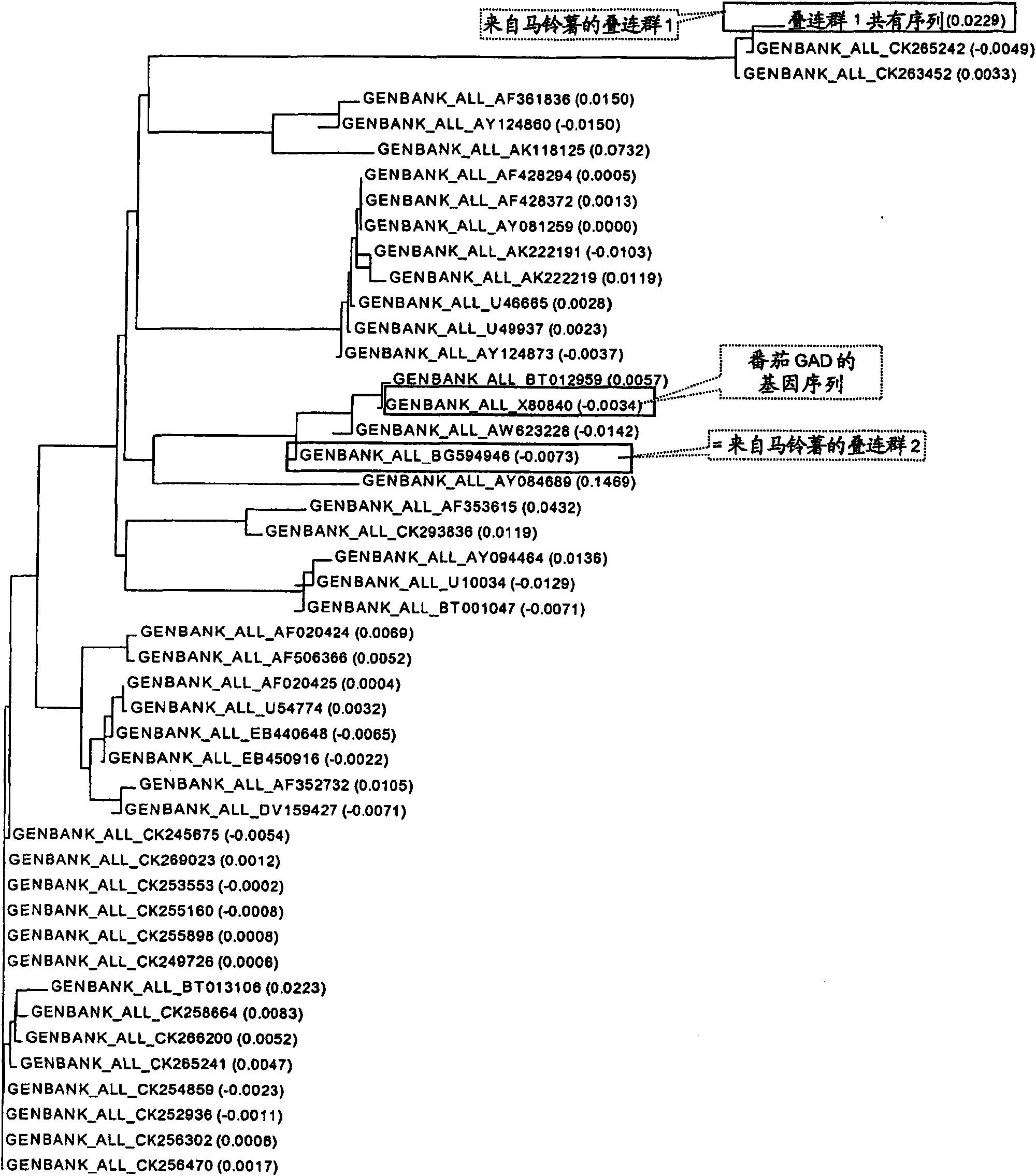

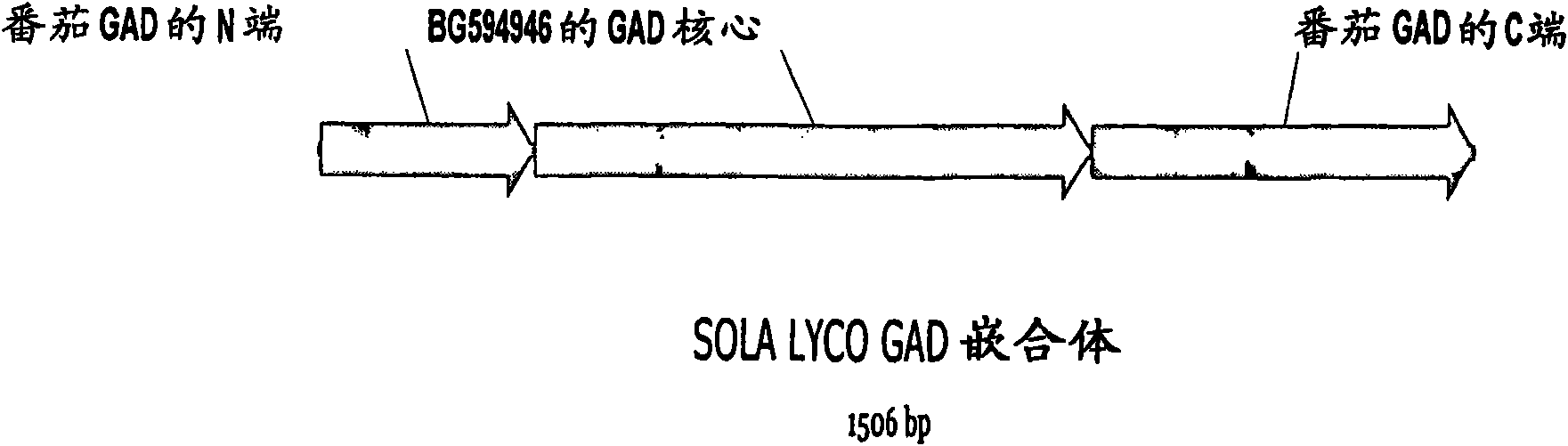

[0216] Example 2: Retrieval of the GAD gene in potato

[0217] To find the unknown gene encoding GAD in potato, the first step was to identify GAD in closely related organisms. A query for "glutamate decarboxylase" of Solanum in the sequence databases Genbank, Refseq and Uniprot revealed a previously characterized GAD in tomato, Swissprot accession number P54767. This sequence was used as a template for tblastn searches in Genbank plant subparts, EST and GSS. Among the 100 best hits (expected value -118 ), 16 sequences were from potato. All 16 sequences are expressed sequence tags (ESTs), ie fragments representing expressed and spliced mRNA. Assembly using VectorNTI Contig Express (settings: overlap=20, identity=0.8, cutoff score=40) shows a contig consisting of 15 sequences, and a second contig consisting of 1 sequence ( BG594946).

[0218]To check the quality of the assembly and decide which contig to choose, the consensus sequence of the two assemblies was generated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com