Permanent-magnet magnetic dehydrator

A dehydrator and magnetic technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of backward technology, long production cycle, and large land occupation, and achieve simple process, short production cycle, and land occupation. small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

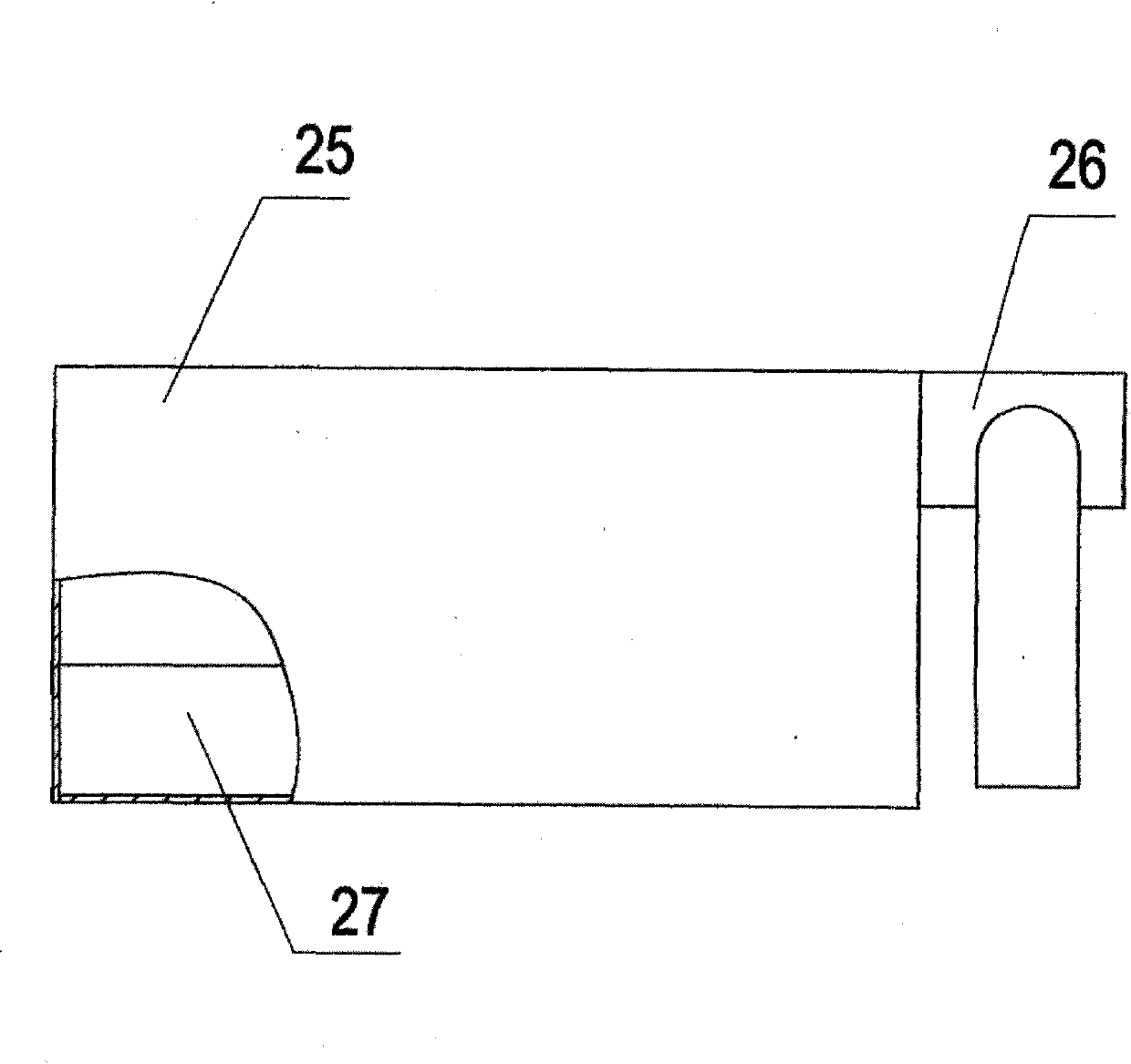

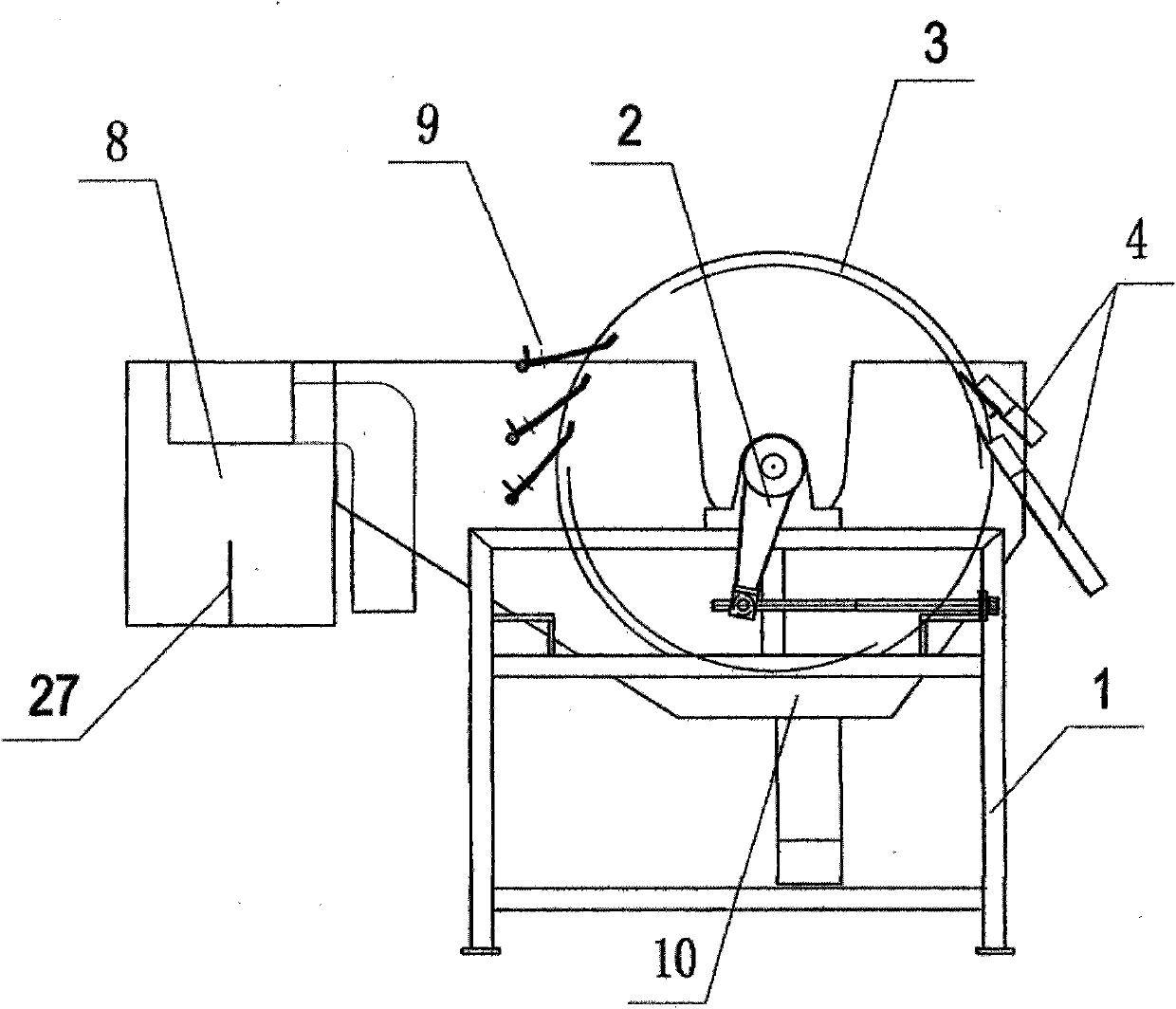

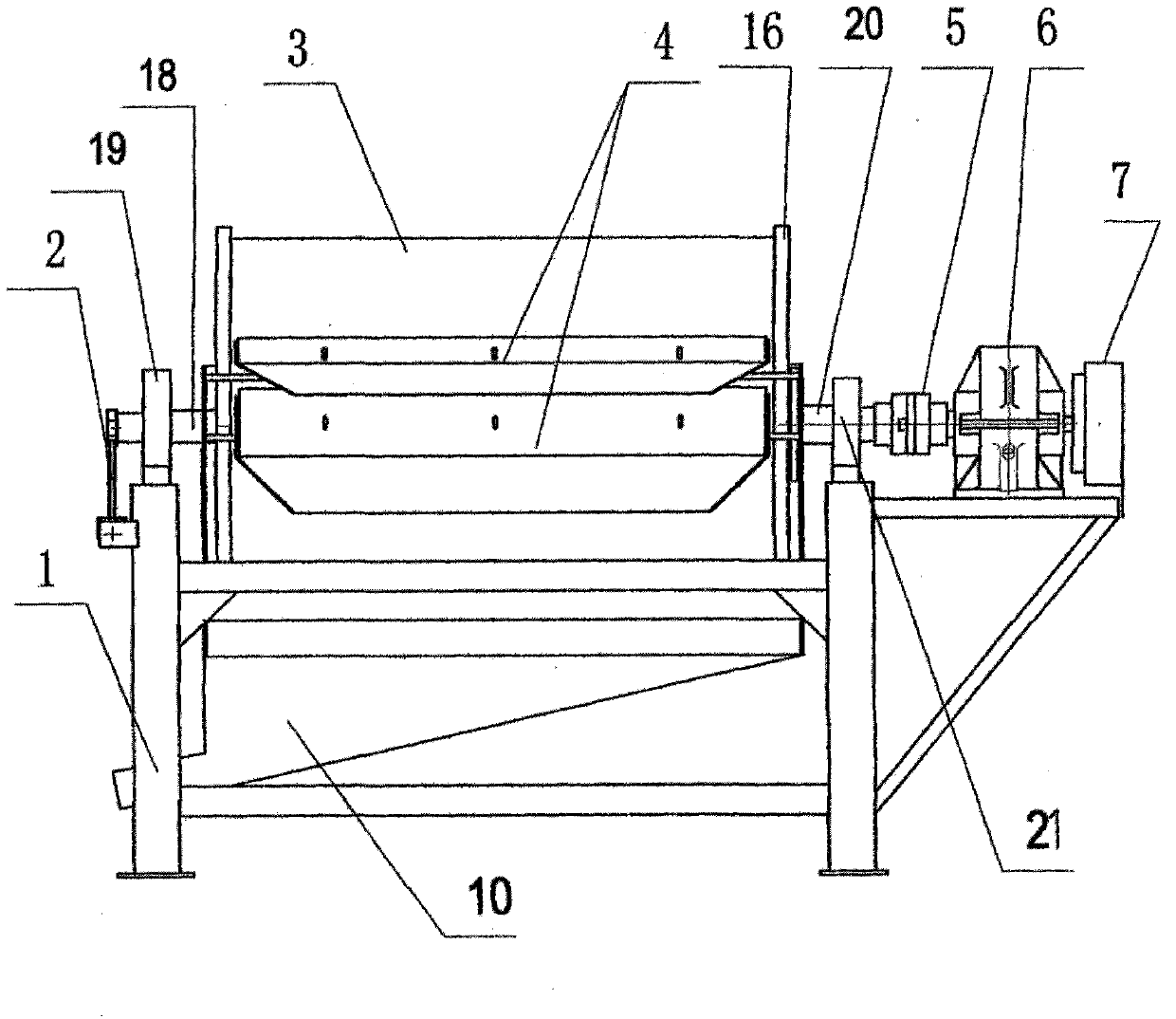

[0013] Referring to the accompanying drawings, the permanent magnetic dehydrator of the present invention includes a frame 1, a coupling 5, a speed reducer 6, a motor 7, and also includes a magnetic system adjustment device 2, a magnetic drum 3, a demineralization device 4, and an ore feeding device 8. Water pressure device 9, tank body 10; frame 1 is composed of power frame and main frame, the main frame is on the left, and the power frame is on the right, which are welded by channel steel and angle steel according to different specifications and models. Install the coupling 5, reducer 6, and motor 7 on the power frame of the frame 1, the pulley on the output shaft sleeve of the motor 7 is connected with the pulley on the input shaft of the reducer 6 through the belt, and the output shaft of the reducer 6 is connected through the coupling The device 5 is connected with the short shaft 20 of the magnetic drum 3; a bearing seat 21 is installed on one side of the main frame by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com