Manufacturing method of GaInP/GaAs/InGaAsP/InGaAs four-junction solar battery

A technology of solar cells and manufacturing methods, applied in the field of solar photovoltaics, can solve problems such as increasing battery manufacturing costs, increasing battery efficiency factors, and increasing battery process difficulties, so as to improve photoelectric conversion efficiency, eliminate factors affecting device performance, and reduce The effect of small heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and easy to understand, the specific embodiments of the present invention will be described in detail below:

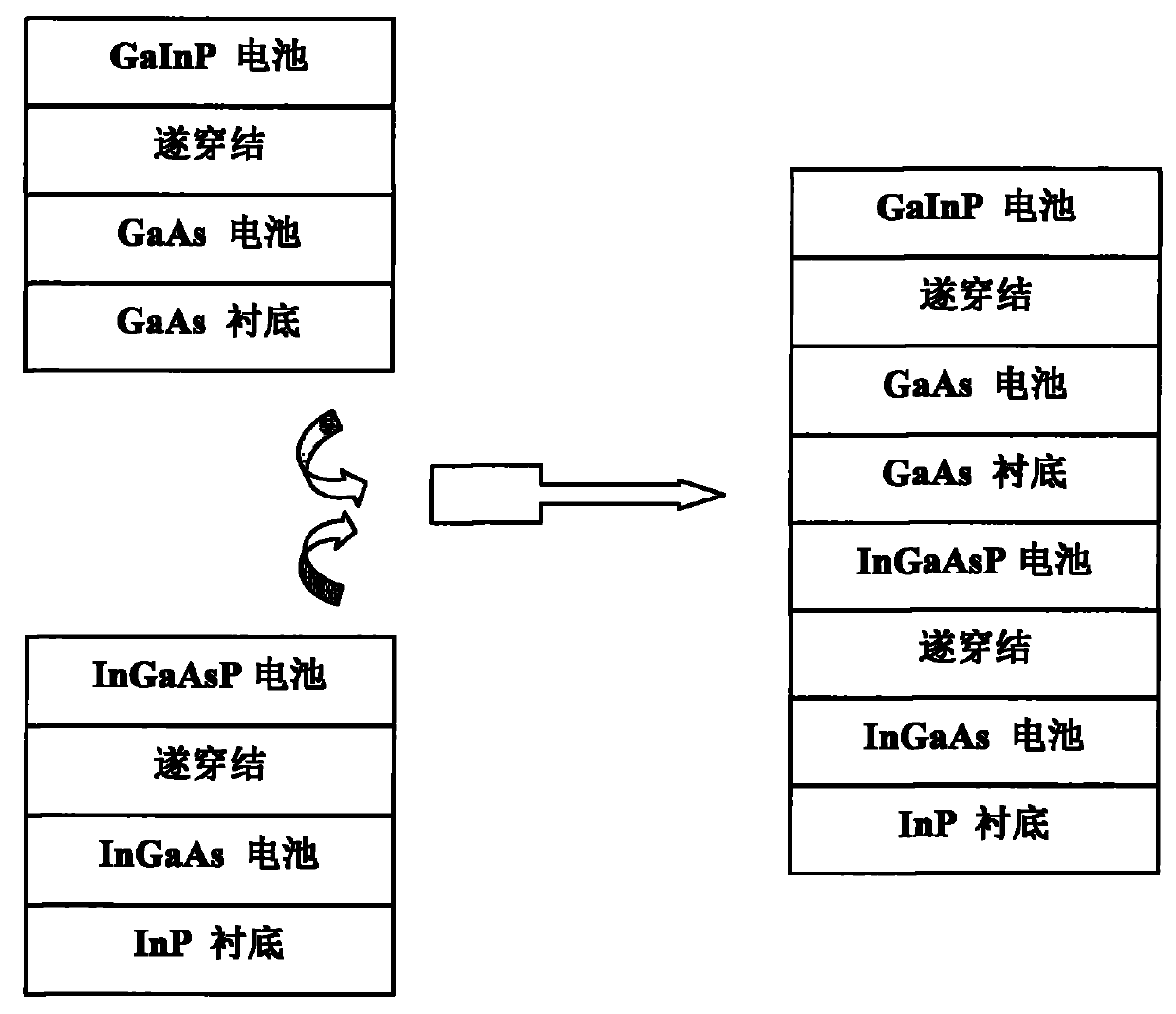

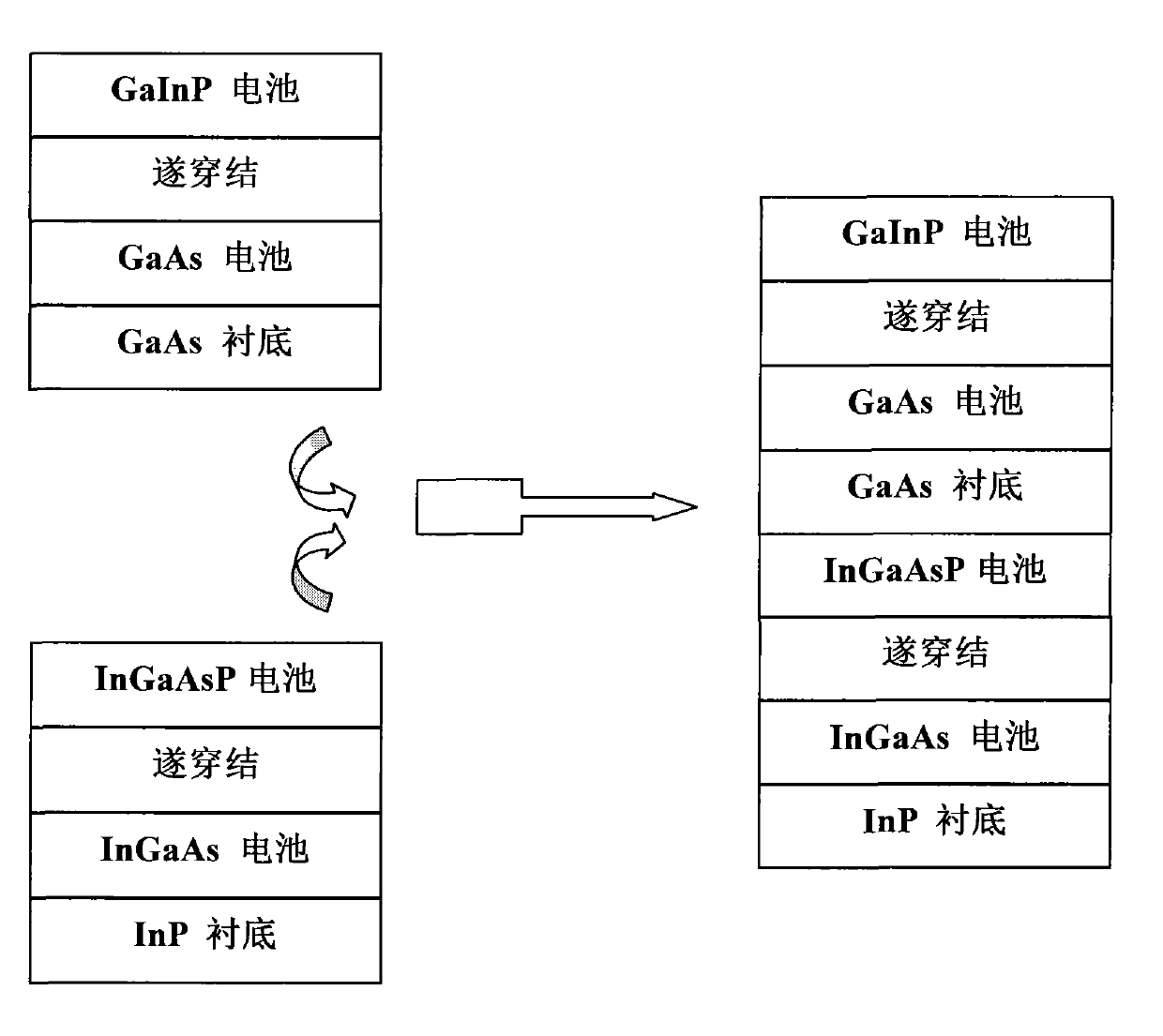

[0020] 1) Cell growth before bonding

[0021] As shown in FIG. 1 , it is a schematic diagram of the cell structure and bonding of the GaInP / GaAs / solar cell and the InGaAsP / InGaAs solar cell used in the present invention before and after bonding. It can be clearly seen from the accompanying drawings: the double-junction cell is grown on the GaAs substrate first with a GaAs cell, and then with a lattice-matched GaInP cell; with a lattice-matched InGaAs cell grown on an InP substrate, and then with a lattice matching InGaAsP cells. Since lattice matching is used for growth, the difficulty of material growth will not be increased due to lattice mismatch, and dislocations will not be generated due to stress release of the epitaxial layer, which will affect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com