Ultra-low-carbon rare earth stainless steel welding wire and preparation method thereof

A stainless steel and ultra-low carbon technology, applied in the direction of manufacturing tools, welding equipment, welding media, etc., can solve problems such as difficult to achieve technical level, slab composition segregation, loose structure, etc., to achieve reasonable composition design, high product quality, cold Effect of Crack Propensity Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

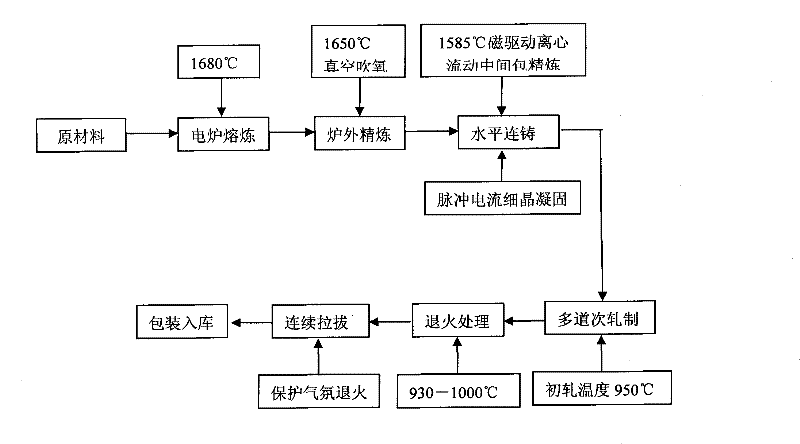

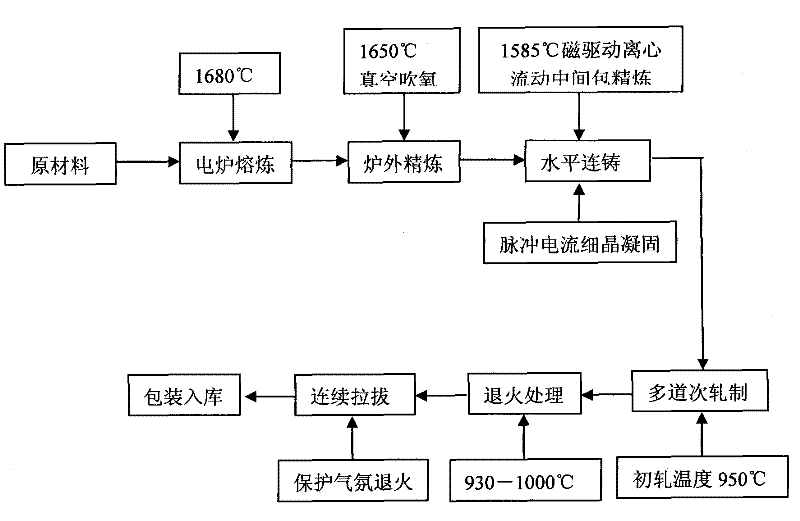

[0048] Embodiment 1 In conjunction with the accompanying drawings, the manufacturing method of the ultra-low carbon rare earth stainless steel welding wire of the present invention, the steps are as follows:

[0049] (1) Desulphurization, dephosphorization and removal of harmful impurities are carried out on the molten steel by vacuum electric furnace melting according to the designed welding wire composition, so that C < 0.5%, and the tapping temperature T ≥ 1650 °C.

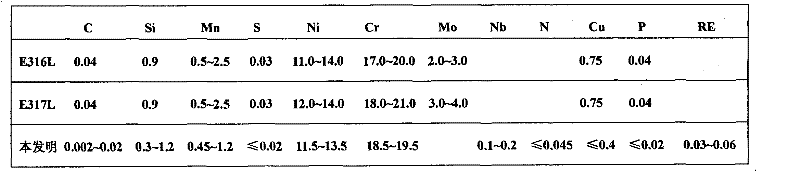

[0050] The chemical composition of the designed welding wire is shown in Table 3.

[0051] table 3

[0052]

[0053] (2) Use AOD to carry out refining outside the furnace at 1630°C, purify molten steel, use vacuum oxygen blowing technology to decarburize, reach C<0.01%, and carry out tundish casting at 1580°C.

[0054] (3) Adopt horizontal continuous casting technology to further refine the molten steel in the tundish, and use electromagnetic drive to centrifugally flow the tundish to purify the molten stee...

Embodiment 2

[0060] Embodiment 2 In conjunction with the accompanying drawings, the manufacturing method of the ultra-low carbon rare earth stainless steel welding wire of the present invention, the steps are as follows:

[0061] (1) Desulphurization, dephosphorization and removal of harmful impurities are carried out on the molten steel by vacuum electric furnace melting according to the designed welding wire composition, so that C < 0.5%, and the tapping temperature T ≥ 1650 °C.

[0062] The chemical composition of the designed welding wire is shown in Table 5.

[0063] table 5

[0064]

[0065] (2) Use AOD to carry out refining outside the furnace at 1680°C to purify molten steel, then use vacuum oxygen blowing technology to decarburize to achieve C<0.01%, and perform tundish casting at 1600°C.

[0066] (3) Adopt horizontal continuous casting technology to further refine the molten steel in the tundish, and use electromagnetic drive to centrifugally flow the tundish to purify the mo...

Embodiment 3

[0072] Embodiment 3 In conjunction with the accompanying drawings, the manufacturing method of the ultra-low carbon rare earth stainless steel welding wire of the present invention, the steps are as follows:

[0073] (1) Desulphurization, dephosphorization and removal of harmful impurities are carried out on the molten steel by vacuum electric furnace melting according to the designed welding wire composition, so that C < 0.5%, and the tapping temperature T ≥ 1650 °C.

[0074] The chemical composition of the designed welding wire is shown in Table 7.

[0075] Table 7

[0076]

[0077] (2) Use AOD to carry out refining outside the furnace at 1650°C, purify molten steel, use vacuum oxygen blowing technology to decarburize, reach C<0.01%, and carry out tundish casting at 1590°C.

[0078] (3) Adopt horizontal continuous casting technology to further refine the molten steel in the tundish, and use electromagnetic drive to centrifugally flow the tundish to purify the molten stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com