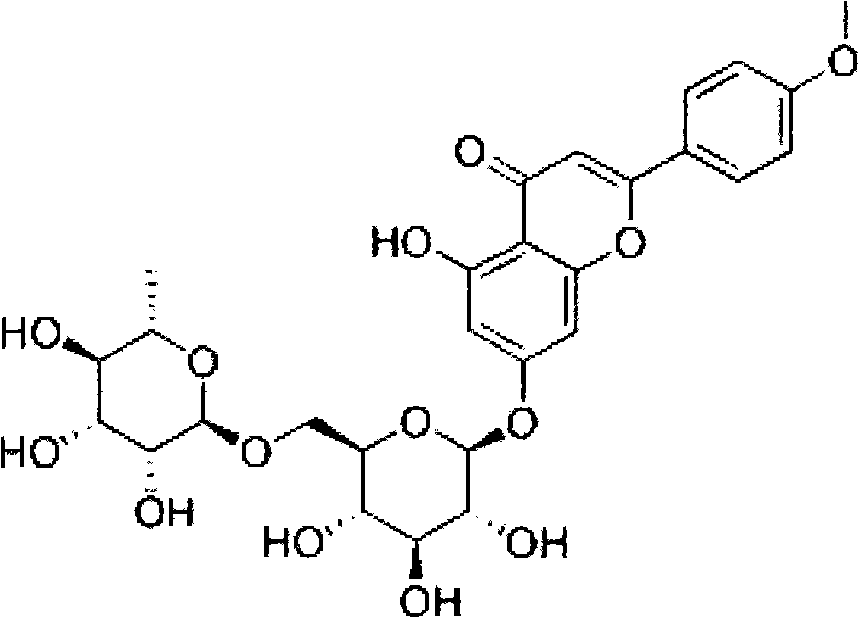

Process for extracting buddleoside

An extraction process and a technology for cylindroside, which is applied in the field of cymenoside extraction technology, can solve problems such as no extraction of cymenoside, and achieve the effects of large preparation amount, simple extraction process and easy industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 1kg of wild chrysanthemum residue after extracting volatile oil and put it into a multi-functional extraction tank, add 10 times the amount of 75% methanol, heat and reflux for 0.5h extraction, filter while hot, extract 3 times, combine the extracts, and put the extracts first in the operating pressure difference Under 0.04Mpa, through the hollow fiber microfiltration membrane with a molecular weight cut-off of 100,000, the permeate A was obtained, and the permeate A was passed through a hollow fiber ultrafiltration membrane with a molecular weight cut-off of 2,000 under the operating pressure difference of 1MPa to obtain the permeate B. The permeate B was passed through a hollow fiber nanofiltration membrane with a molecular weight cut-off of 500 under the operating pressure difference of 1.0Mpa to obtain a concentrated solution, the concentrated solution was coated with AB-8 macroporous resin, and eluted with 65% ethanol until TLC was used. Fraction, collect the e...

Embodiment 2

[0025] Take 1kg of wild chrysanthemum residue after extraction of volatile oil and put it into a multi-functional extraction tank, add 6 times the amount of methanol, heat and reflux for extraction for 1 hour, filter while hot, extract 4 times, combine the extracts, and first put the extract under the operating pressure difference of 0.08Mpa The permeate A was processed by a hollow fiber microfiltration membrane with a molecular weight cut-off of 150,000. The permeate A was passed through a hollow fiber ultrafiltration membrane with a molecular weight cut-off of 3,000 under an operating pressure difference of 1.3 MPa to obtain a permeate B. Liquid B was passed through a hollow fiber nanofiltration membrane with a molecular weight cut-off of 400 under an operating pressure difference of 0.9 Mpa, and the concentrated solution was collected. The concentrated solution was applied to S-8 macroporous resin, and the methanol was eluted to TLC to detect the fraction without stigma. Col...

Embodiment 3

[0027] Take 2 kg of wild chrysanthemum residue after extracting volatile oil and put it into a multifunctional extraction tank, add 12 times the amount of deionized water, heat and reflux for extraction for 1.5 hours, filter while hot, extract twice, combine the extract, and put the extract first in the operating pressure difference Under 0.15Mpa, the permeate A is processed by a hollow fiber microfiltration membrane with a molecular weight cut-off of 200,000, and the permeate A is passed through a hollow fiber ultrafiltration membrane with a molecular weight cut-off of 4,000 under the operating pressure difference of 2MPa to obtain permeate B. The permeate B was passed through a hollow fiber nanofiltration membrane with a molecular weight cut-off of 300 under the operating pressure difference of 1.2Mpa, and the concentrated solution was collected. The concentrated solution was coated with HPD-600 macroporous resin and eluted with 60% ethanol until TLC detected no smears. The g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com