Method for preparing leather fat liquor by treating electrostatic acids by spraying method

A technology of leather fatliquor and electrostatic acid, which is applied in the field of leather fatliquor preparation, to achieve full utilization of resources, good waxy feeling, and clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

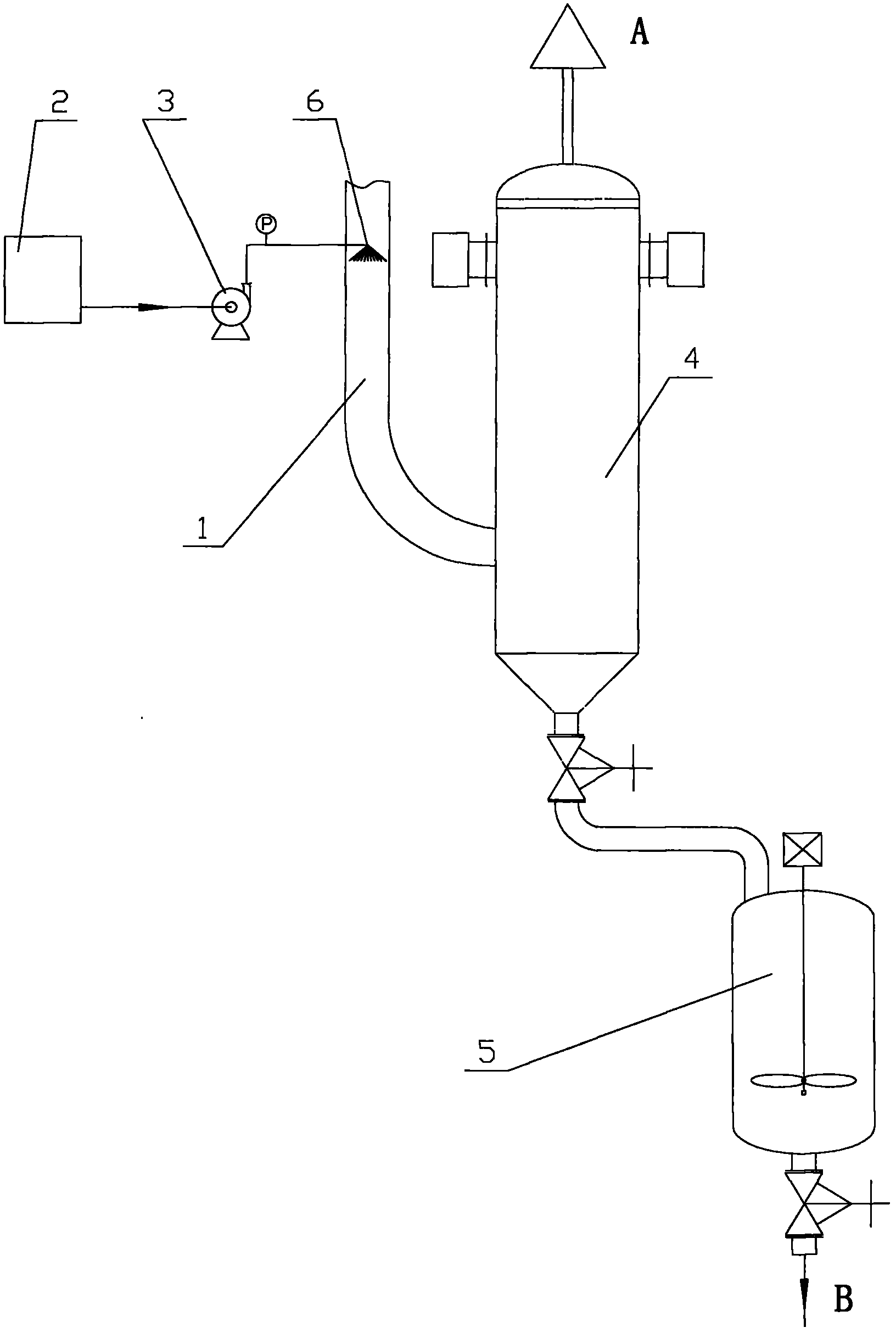

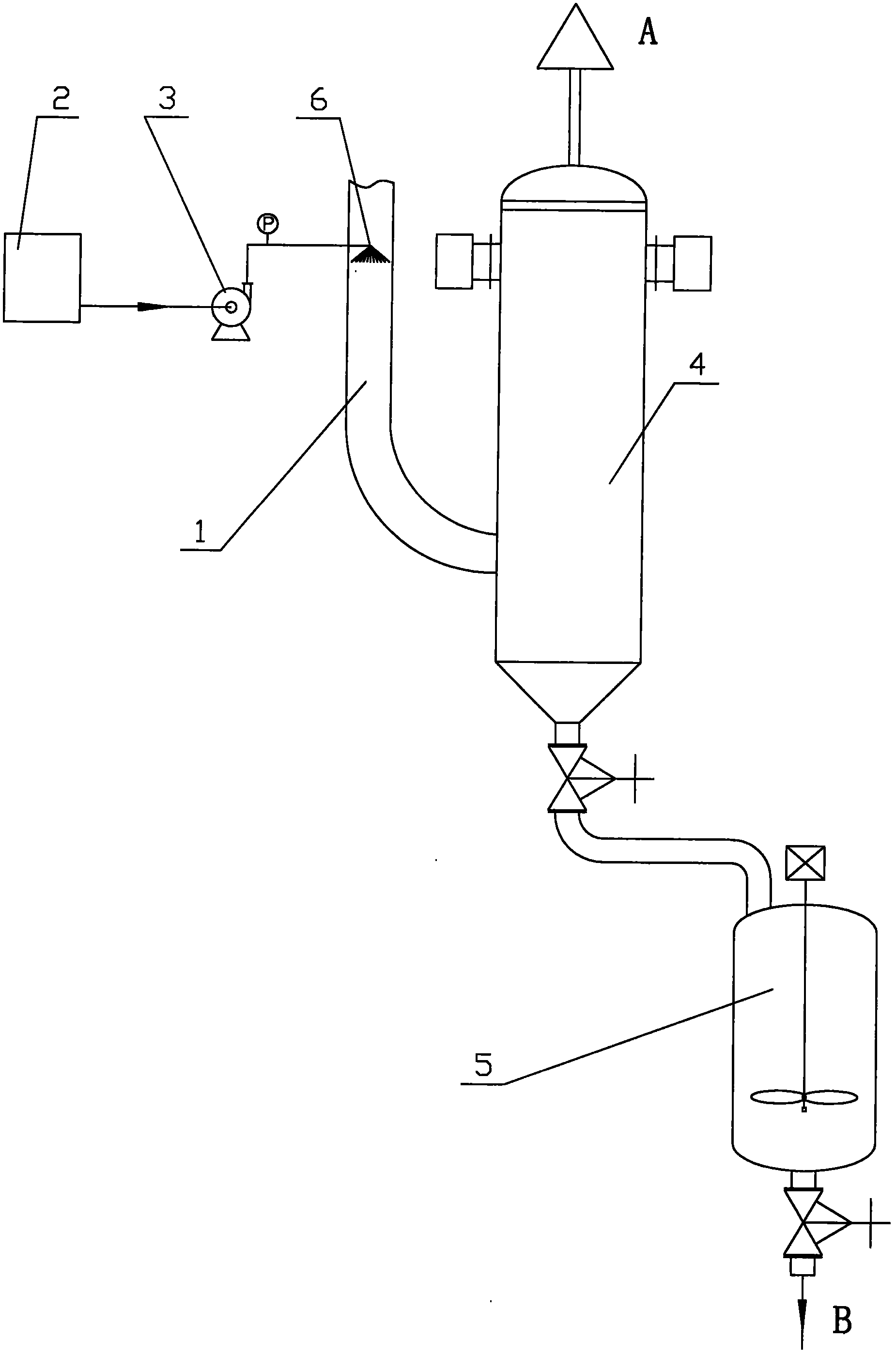

Method used

Image

Examples

Embodiment 1

[0020] Spray vegetable oil into the tail gas pipeline, the flow rate per hour is 35kg, the flow rate of electrostatic acid is 7kg per hour, the pressure of the metering pump is 1.2MPa, after the reaction, the material enters the 1-ton reactor, and the material in the reactor is adjusted to reach about 1 ton. Stop Enter, switch to another stirring reactor, start stirring, slowly add ammonia water for neutralization, after neutralization, the pH is 6.0, add 60kg of hydrogen peroxide (27.5%), decolorize at 75°C for 10 hours, after the color meets the requirements, add preservatives Kayson 1kg, add water to adjust the solid content to 70.3%, to obtain a fatliquor product.

Embodiment 2

[0022] Spray fish oil into the tail gas pipeline, the flow rate per hour is 50kg, the flow rate of electrostatic acid is 7kg per hour, the pressure of the metering pump is 1.6MPa, after the reaction, the material enters the 1-ton reactor, and the material in the reactor is adjusted to reach about 1 ton. Stop Enter, switch to another stirring reactor, start stirring, slowly add sodium hydroxide to neutralize, the pH after neutralization is 6.5, add 40kg of hydrogen peroxide (27.5%), decolorize at 70°C for 6 hours, after the color meets the requirements, add Preservative sodium benzoate 1kg, add water to adjust the solid content to 71.5%, to obtain a fatliquor product.

Embodiment 3

[0024] Soybean oil is sprayed into the tail gas pipeline, the flow rate per hour is 60kg, the flow rate of electrostatic acid is 7kg per hour, the pressure of the metering pump is 2.0MPa, the material after the reaction enters the 1-ton reactor, and the material in the reactor is adjusted to reach about 1 ton. Stop Enter, switch to another stirred reactor, start stirring, slowly add diethanolamine to neutralize, the pH after neutralization is 7.1, add 50kg of hydrogen peroxide (27.5%), decolorize at 65°C for 5 hours, after the color meets the requirements, add anti-corrosion Potassium sorbate 1kg, add water to adjust to contain solid 69.8%, obtain fatliquor product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com