A kind of comprehensive fatliquoring agent for leather and preparation method thereof

A fatliquor, leather technology, applied in leather impregnation, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, etc. It is not good, the amount of solvent is large, etc., to achieve the effect of good leather softness and fullness, good appearance and fluidity, and improved softness and feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

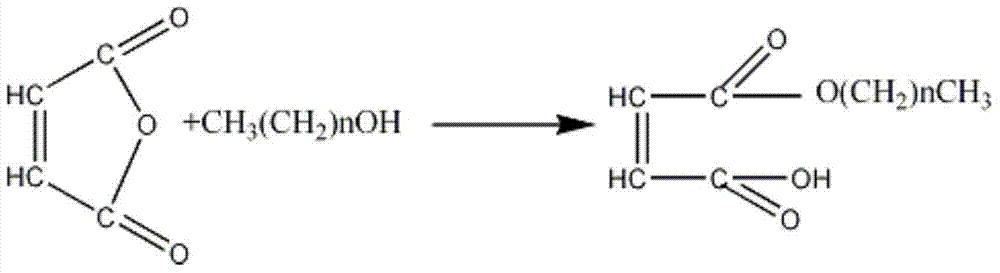

Method used

Image

Examples

Embodiment 1

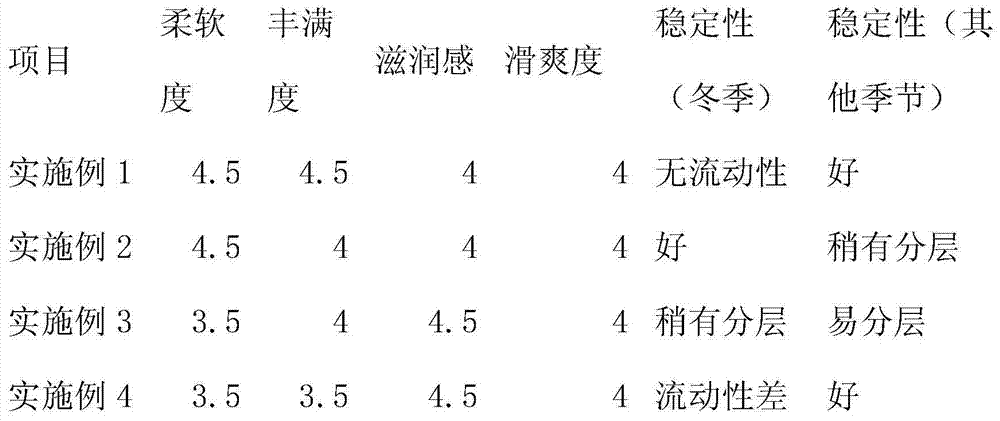

[0022] 1. Set the mass ratio to C 8 -C 10 Alcohol: C 12 -C 14 Alcohol: C 16 -C 18 Alcohol = 8%: 80%: 12% mixed straight-chain saturated alkyl alcohol and maleic anhydride in a molar ratio of 1:1, and reacted at 100°C for 6 hours to obtain a mixed straight-chain saturated alkyl alcohol Carbon alcohol esterification; then add anhydrous sodium sulfite by mixing linear saturated alkyl higher carbon alcohol esterification and anhydrous sodium sulfite at a molar ratio of 1:1, and react at 85°C for 4 hours to obtain straight chain saturated alkyl higher carbon alcohol of esterified sulfitated products.

[0023] 2. Lower the temperature of the esterified sulfitation product of the above-mentioned straight chain saturated alkyl higher alcohol to 60°C, and measure by mass ratio: the esterification sulfitation product of straight chain saturated alkyl higher alcohol: modified soybean lecithin : Sulfitated rapeseed oil: Lanolin: Natural beef hoof oil: No. 10 white oil: Sodium lauryl...

Embodiment 2

[0025] 1. The mass ratio is: C 8 -C 10 Alcohol: C 12 -C 14 Alcohol: C 16 -C 18 Alcohol = 12%: 80%: 8% mixed straight-chain saturated alkyl alcohol and maleic anhydride in a molar ratio of 1:0.8, and reacted at 100°C for 6 hours to obtain a mixed straight-chain saturated alkyl alcohol Carbon alcohol esterification; then add sodium metabisulfite by mixing straight chain saturated alkyl high carbon alcohol and sodium metabisulfite at a molar ratio of 1:0.4, and react at 80°C for 4 hours to obtain the esterification of straight chain saturated alkyl high carbon alcohol Sulfation product.

[0026] 2. Lower the temperature of the esterified sulfitation product of the above-mentioned straight chain saturated alkyl higher alcohol to 60°C, and measure by mass ratio: the esterification sulfitation product of straight chain saturated alkyl higher alcohol: modified soybean lecithin : Sulfitated rapeseed oil: Lanolin: Natural beef hoof oil: No. 10 white oil: Sodium lauryl sulfate: Wa...

Embodiment 3

[0028] 1. The mass ratio is: C 8 -C 10 Alcohol: C 12 -C 14 Alcohol: C 16 -C 18 Alcohol = 15%: 75%: 10% mixed straight-chain saturated alkyl alcohol and maleic anhydride in a molar ratio of 1:0.6, and reacted at 150°C for 2 hours to obtain a mixed straight-chain saturated alkyl alcohol Carbon alcohol esterification; then add anhydrous sodium sulfite by mixing straight chain saturated alkyl higher alcohol and anhydrous sodium sulfite at a molar ratio of 1:0.6, and react at 80°C for 4 hours to obtain ester of straight chain saturated alkyl higher alcohol sulfitation products.

[0029] 2. The esterification sulfitation product of the above-mentioned straight-chain saturated alkyl high-carbon alcohol is cooled to 60° C., and the esterification sulfitation product of the straight-chain saturated alkyl high-carbon alcohol is: modified soybean lecithin: sulfite Sulfated rapeseed oil: lanolin: natural beef hoof oil: No. 10 white oil: sodium lauryl sulfate: water = 25:12:8:2:2:3:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com