Post-processing edge pre-shaped slab and preparation method thereof

A board and edge technology, which is applied to the pre-formed board and its production field for post-processing edges, can solve the problems of waste efficiency and other problems, and achieve the effect of easy cutting and opening, reducing loss and saving daily loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

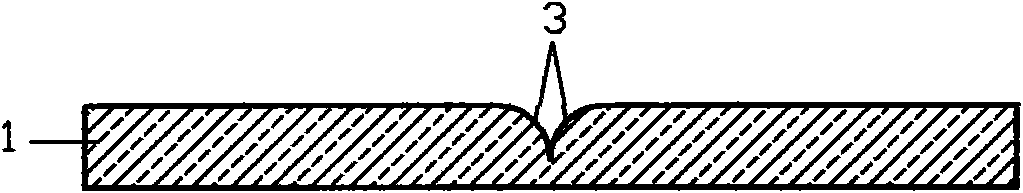

[0058] The present invention is a preformed sheet material for later processing edge and its manufacturing method, so as to make a plate with a size of 600mm×600mm such as figure 1 As shown in the middle, a cross-sectional section is preset to form a porcelain tile plate with a predetermined combination of arc-shaped openings as an example. The production process includes the following steps:

[0059] (1) Prepare the raw materials for the production of porcelain tiles and the production line mainly composed of raw material conveying system, press, drying kiln and firing kiln;

[0060] (2), ready as Figure 4 The press molding mold for making porcelain tiles with a size of 600mm×600mm is shown in the figure. This molding mold has been designed and manufactured in advance so that a cross-sectional section is preset in the middle. Form the convex structure shape of the arc shape with the angle, depth and size shown in the label 3, and install the forming mold and its supporting ...

Embodiment 2

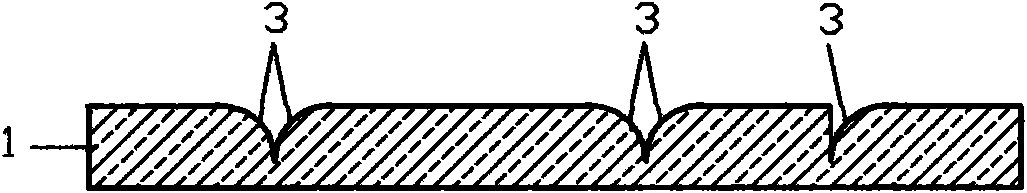

[0067] The present invention is a preformed sheet material for later processing edge and its manufacturing method, so as to make a plate with a size of 600mm×600mm such as figure 2 As shown in the middle, 2 cross-sections are preset to form a predetermined combination arc opening, and 1 cross-section is a predetermined single-sided arc opening, which can be cut in equal parts to form 5 pieces, each with a size of 120mm×600mm Taking the porcelain tile plate as an example, the production process includes the following steps:

[0068] (1) Prepare the raw materials for the production of porcelain tiles and the production line mainly composed of raw material conveying system, press, drying kiln and firing kiln;

[0069] (2), ready as Figure 5 The press molding mold for making porcelain tiles with a size of 600mm×600mm is shown in the figure. This molding mold has been designed and manufactured in advance so that 3 cross-sectional sections are preset in the middle, as shown in th...

Embodiment 3

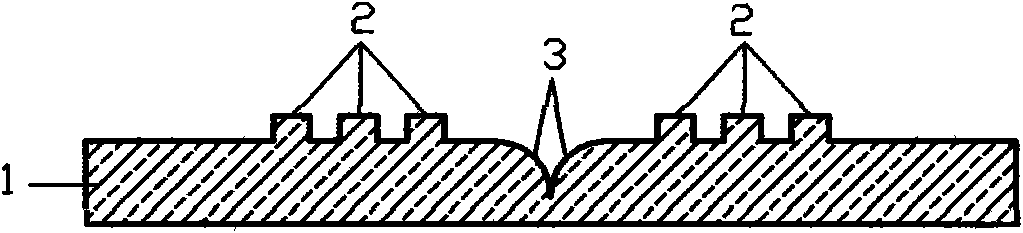

[0076] The present invention is a preformed sheet material for later processing edge and its manufacturing method, so as to make a plate with a size of 600mm×600mm such as image 3 As shown in the middle, a cross-section is pre-formed, which is a pre-combined arc-shaped opening, and the two sides are pre-formed with three convex ribs as an example. The production process includes the following steps:

[0077] (1) Prepare the raw materials for the production of porcelain tiles and the production line mainly composed of raw material conveying system, press, drying kiln and firing kiln;

[0078] (2), ready as Figure 6 The press molding mold for making porcelain tiles with a size of 600mm×600mm is shown in the figure. This molding mold has been designed and manufactured in advance so that a cross-sectional section is preset in the middle. Form the convex structure shape of the angle, depth and size of the arc shape shown in the label 3, and also have the convex structure shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com