Aromatic polycarbonate resin composition and molded article thereof

A technology of polycarbonate resin and resin composition, applied in information storage, instruments, optics, etc., can solve problems such as increased haze of resin composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0169] (I) Manufacture of pellets

[0170] Pellets were produced according to the following steps (i) to (iii).

[0171] (Step (i): Preparation of particle-containing resin (component B))

[0172] (Preparation of coated lanthanum hexaboride particles (component B-1))

[0173] 8 parts by weight of lanthanum hexaboride particles (manufactured by Sumitomo Metal Mining Co., Ltd.: KHDS-06) with an average particle diameter of 80 nm were mixed with 0.5 parts by weight of γ-aminopropyltriethoxysilane as a silane coupling agent and In 392 parts by weight of water, γ-aminopropyltriethoxysilane was adsorbed on the surface of the lanthanum hexaboride particle for surface modification.

[0174] Next, after removing the water with a centrifuge, add 45 parts by weight of tetraethoxysilane to a mixed solvent of surface-modified lanthanum hexaboride particles, 280 parts by weight of ethanol, and 70 parts by weight of water, and polymerize in six parts by hydrolysis. A coating film of silic...

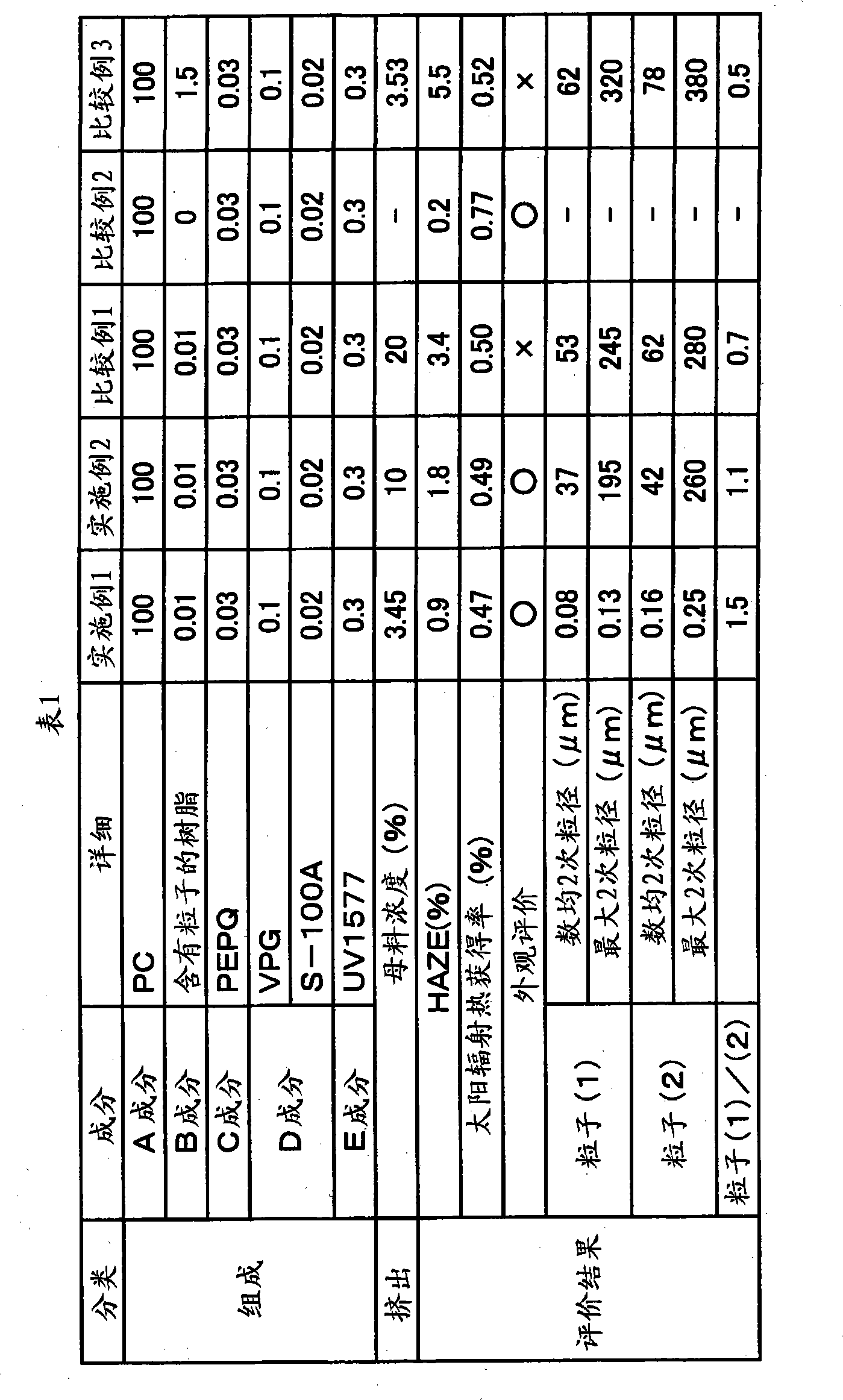

Embodiment 2

[0193] In the step (ii), 0.09 parts by weight of PC (component A) and 0.01 parts by weight of the particle-containing resin (component B) were uniformly mixed with a super floater to obtain a masterbatch of 0.1 parts by weight.

[0194] In addition, in the process (ii-1), 0.1 parts by weight of masterbatch and 4.45 parts by weight of PC (component A), 0.02 parts by weight of S100A, 0.03 parts by weight of PEPQ, 0.10 parts by weight of VPG and 0.30 parts by weight of UV1577 was uniformly mixed with a roller to obtain 5 parts by weight of secondary masterbatch for supplying to the extruder.

[0195] Pellets were produced in the same manner as in Example 1 except for the above steps. Then, the same molding as in Example 1 was performed to prepare a test piece. Table 1 shows the evaluation results of the obtained test pieces.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com