Method for preparing high-activity lemon diet fibers

A lemon dietary fiber, high activity technology, applied in food preparation, food science, application and other directions, can solve the problems of complex preparation process and required equipment, active ingredient destruction, complex process flow, etc., to improve food tissue structure and viscosity. , easy to operate, the effect of simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In the present embodiment, the processing steps of preparing lemon dietary fiber are as follows in sequence:

[0041] (1) Enzyme inactivation treatment

[0042] Take 200 g of the remaining fresh peel residue after squeezing the fresh lemon fruit, and scald it in 100°C water for 4 minutes;

[0043] (2) cooling and dehydration

[0044] The lemon peel residue after the enzyme-inactivating treatment in step (1) is cooled to room temperature by washing with tap water, and then it is dehydrated by a centrifuge, the centrifuge speed is 1000rpm, and the dehydration time is 3 minutes;

[0045] (3) Segmentation

[0046] Cutting lemon peels with a dimension greater than 7 mm in any direction in the dehydrated lemon peels in step (2) into small pieces with a particle size of about 4 mm;

[0047] (4) Ethanol extraction

[0048] The dehydrated and cut lemon peel is weighed, and the ethanol is measured according to the ratio of the weight of the lemon peel (gram): the volume (mill...

Embodiment 2

[0054] In the present embodiment, the processing steps of preparing lemon dietary fiber are as follows in sequence:

[0055] (1) Enzyme inactivation treatment

[0056] Take 200 g of the remaining fresh skin residue after squeezing the fresh lemon fruit, and scald it in 95°C water for 5 minutes;

[0057] (2) cooling and dehydration

[0058] The lemon peel residue after step (1) deenzyme treatment is cooled to room temperature by washing with tap water, and then it is dehydrated by a centrifuge, the centrifuge speed is 900rpm, and the dehydration time is 4 minutes;

[0059] (3) Segmentation

[0060] Cutting lemon peels with a size greater than 7 mm in any direction in the dehydrated lemon peels in step (2) into small pieces with a particle size of about 5 mm;

[0061] (4) Ethanol extraction

[0062] The dehydrated and cut lemon peel is weighed, and the ethanol is measured according to the weight of the lemon peel (gram): the volume (milliliter) of ethanol = 1: 2.5, and the e...

Embodiment 3

[0068] In the present embodiment, the processing steps of preparing lemon dietary fiber are as follows in sequence:

[0069] (1) Enzyme inactivation treatment

[0070] Take 200 g of the remaining fresh peel residue after squeezing the fresh lemon fruit, and scald it in 95°C water for 6 minutes;

[0071] (2) cooling and dehydration

[0072] The lemon peel residue after step (1) deenzyme treatment is cooled to room temperature by washing with tap water, and then it is dehydrated by a centrifuge, the centrifuge speed is 800rpm, and the dehydration time is 5 minutes;

[0073] (3) Segmentation

[0074] Cutting lemon peels with a size greater than 7mm in any direction in the dehydrated lemon peels in step (2) into small pieces with a particle size of about 7mm;

[0075] (4) Ethanol extraction

[0076] The dehydrated and cut lemon peel is weighed, and the ethanol is measured according to the ratio of the weight of the lemon peel (gram): the volume (milliliter) of ethanol = 1: 2, ...

PUM

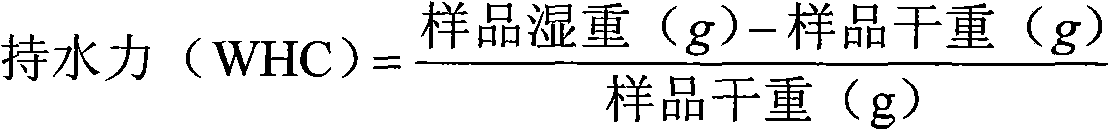

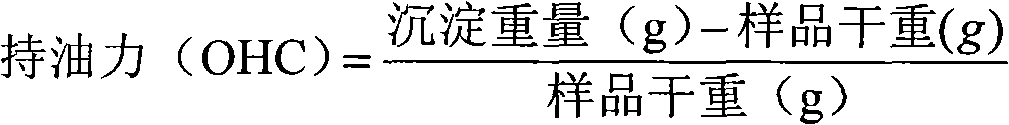

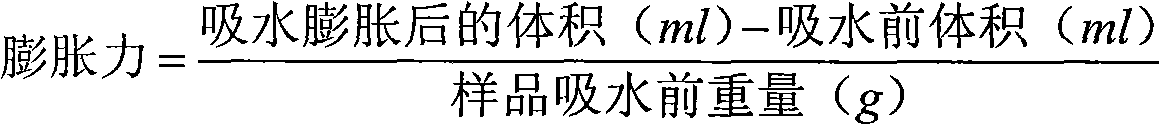

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Water holding capacity | aaaaa | aaaaa |

| Oil holding power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com