Method for synthesizing nano cerium oxide with different morphologies by hydrothermal method

A nano-cerium oxide, hydrothermal method, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds and other directions, can solve the problems of complex preparation process, troublesome post-processing, restricting the development of nano-materials, etc. The effect of uniform reaction conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

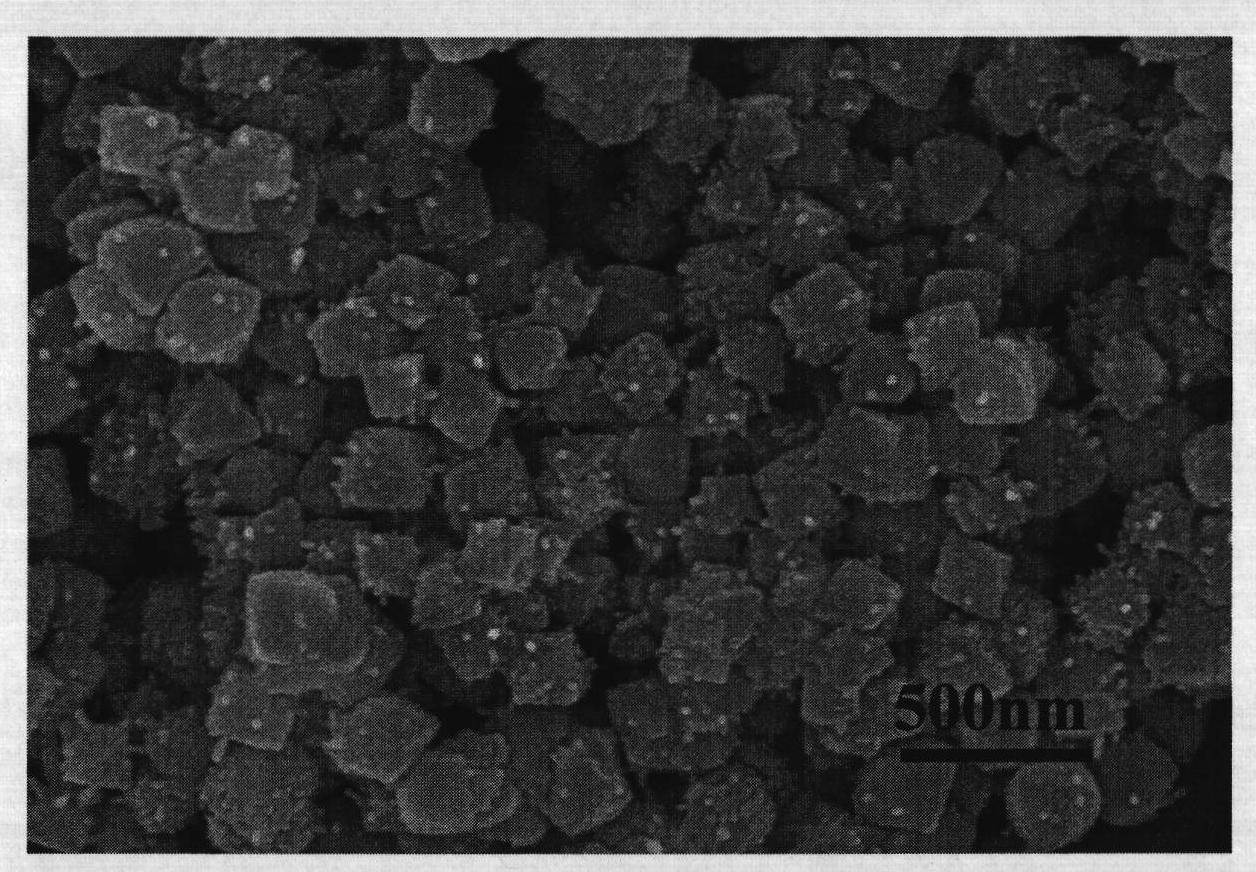

Embodiment 1

[0041] 1) Prepare Ce(NO at a concentration of 0.02mol / L at room temperature 3 )·6H 2 O aqueous solution;

[0042] 2) Add 4mlCe(NO 3 )·6H 2 O aqueous solution, 4m toluene and 2ml H 2 o 2 , into a high-temperature reaction kettle with a sealing device and a liner coated with a layer of tetrafluoroethylene, without any stirring;

[0043] 3) React at 150°C for 2 hours;

[0044] 4) After the reaction is finished, pour off the upper layer solution, and the nano-cerium oxide will directly sink to the bottom of the reaction kettle, and then add ethanol to disperse.

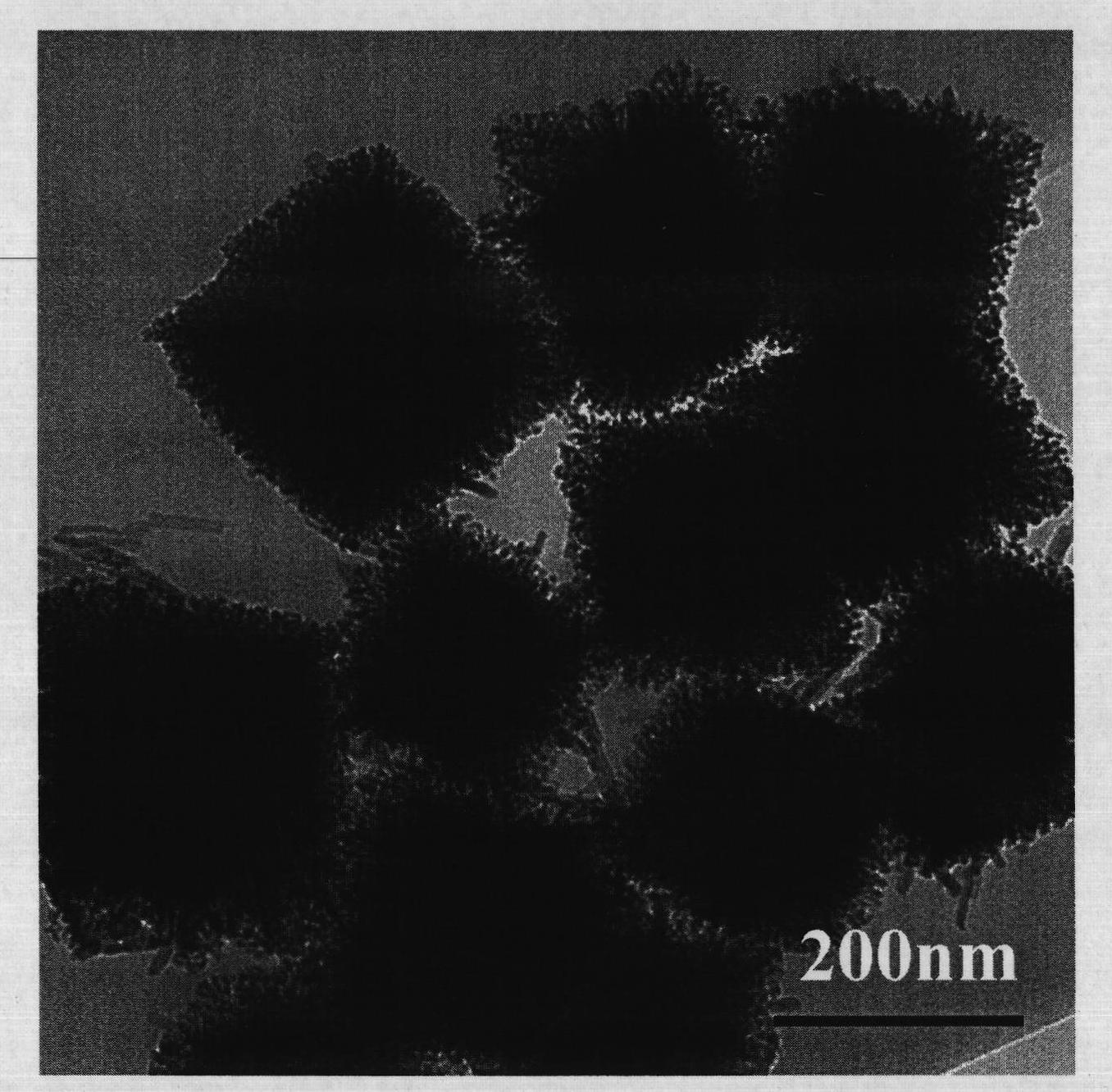

Embodiment 2

[0046] 1) Ce(NO 3 )·6H 2 O aqueous solution;

[0047] 2) Add 12mlCe(NO 3 )·6H 2 O aqueous solution, 14m toluene and 3ml H2 o 2 , into a high-temperature reaction kettle with a sealing device and a liner coated with a layer of tetrafluoroethylene, without any stirring;

[0048] 3) React at 180°C for 36 hours;

[0049] 4) After the reaction is finished, pour off the upper layer solution, and the nano-cerium oxide will directly sink to the bottom of the reaction kettle, and then add ethanol to disperse.

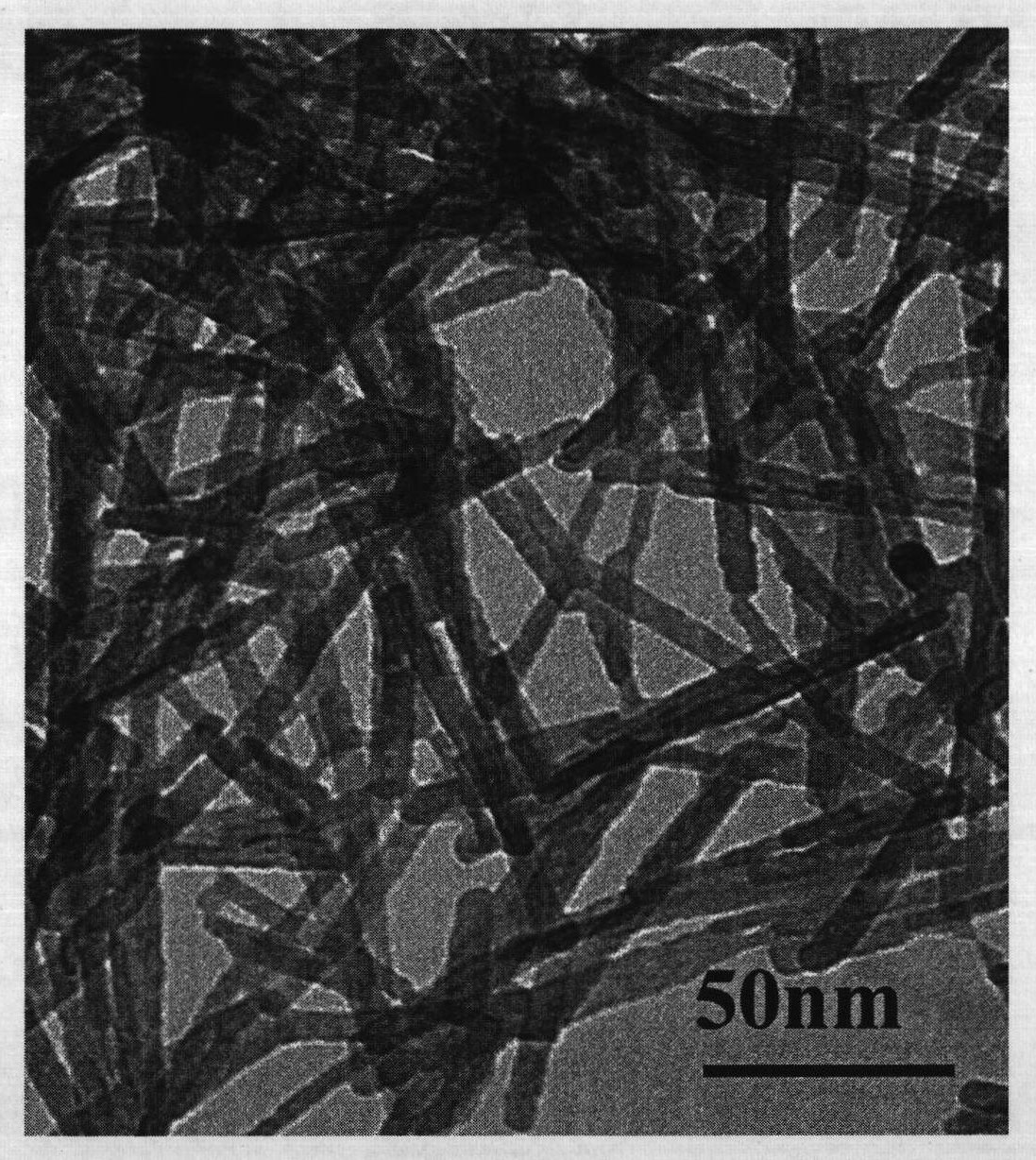

Embodiment 3

[0051] 1) Ce(NO 3 )·6H 2 O aqueous solution;

[0052] 2) Add 24mlCe(NO 3 )·6H 2 O aqueous solution, 24m toluene and 3ml H 2 o 2 , into a high-temperature reaction kettle with a sealing device and a liner coated with a layer of tetrafluoroethylene, without any stirring;

[0053] 3) React at 240°C for 72 hours;

[0054] 4) After the reaction is finished, pour off the upper layer solution, and the nano-cerium oxide will directly sink to the bottom of the reaction kettle, and then add ethanol to disperse.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com