Stone slab surface profile size measurement device and measurement method thereof

A measuring device and stone technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inconvenient continuous operation and scientific management of stone processing factories, reduction of stone utilization rate, large measurement errors, etc. Stone design and processing level, convenient and scientific management, the effect of reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the drawings.

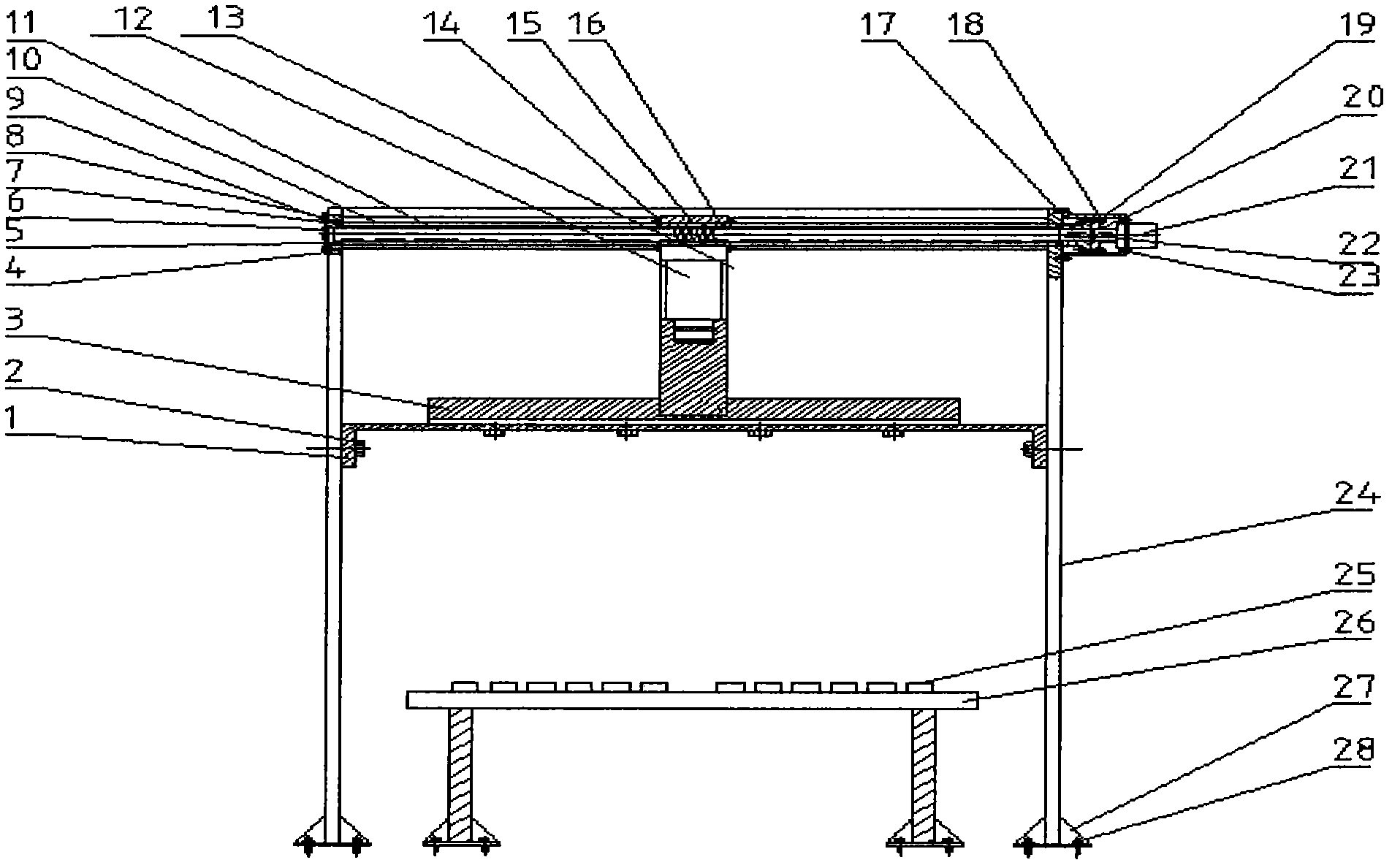

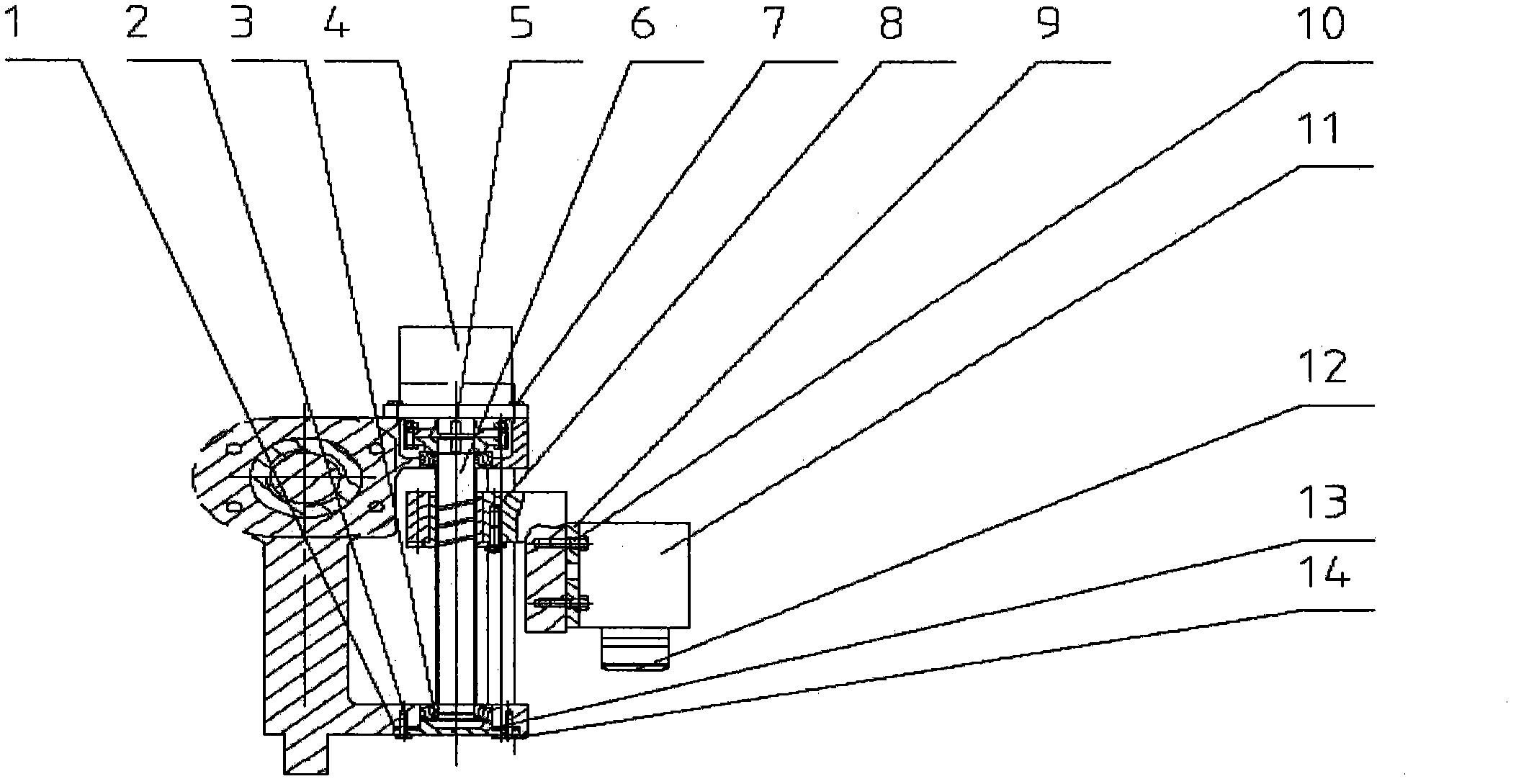

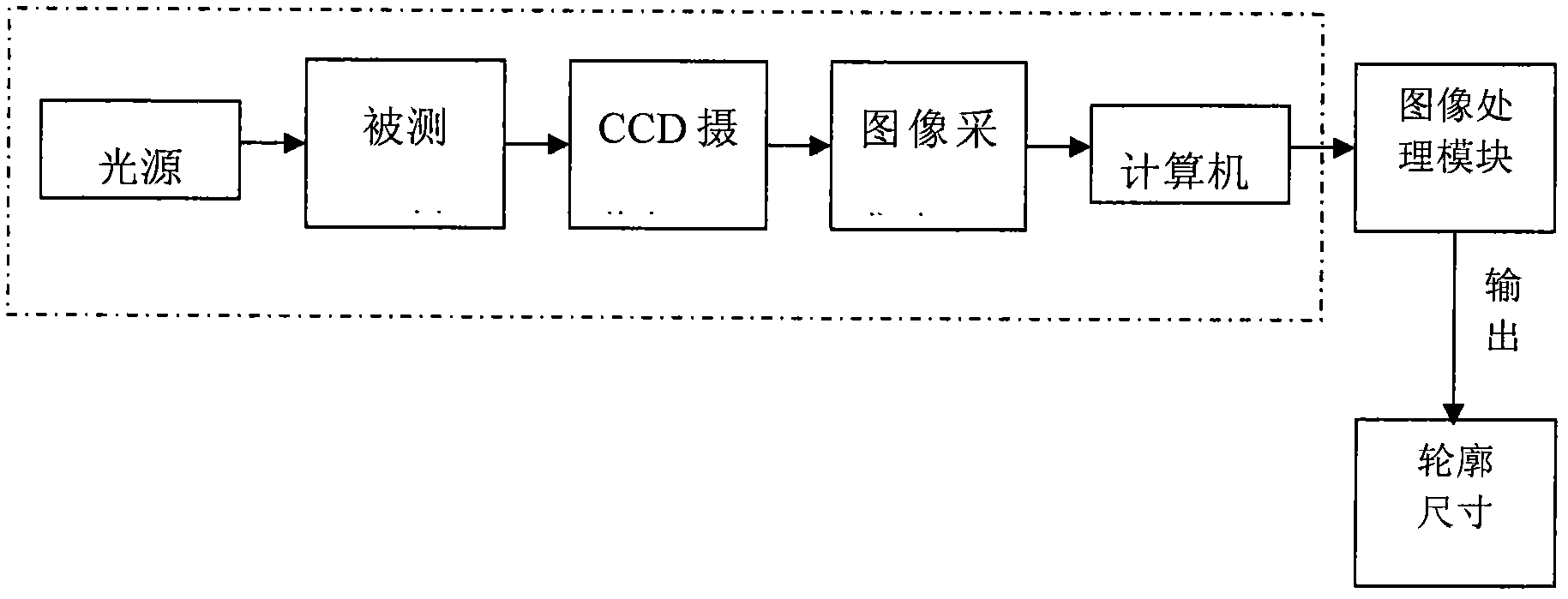

[0020] The invention is a measuring device for the surface profile and topography of natural stone after polishing, and mainly consists of a CCD camera system, a lens control system and a mechanical movement and support mechanism. The device includes a hardware part and a software part. The hardware part includes the stone slab worktable, the camera supports and stands, the camera horizontal movement and the vertical movement guide rail, the camera horizontal movement and the vertical movement drive the servo motor. The camera system includes a CCD camera, a CCD camera control circuit and so on. The software is mainly based on C++ language to compile MCU control program, camera control program, image processing control program, image acquisition and size measurement control program.

[0021] The invention is mainly applied to the stone polishing production line, and at the same time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com