Sound wave electrooxidation process for waste water treatment

A technology of electro-oxidation and sonic wave, which is applied in the field of sonic electro-oxidation technology for wastewater treatment, can solve the problems of high equipment cost and large investment, and achieve the effects of energy saving, stable process operation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

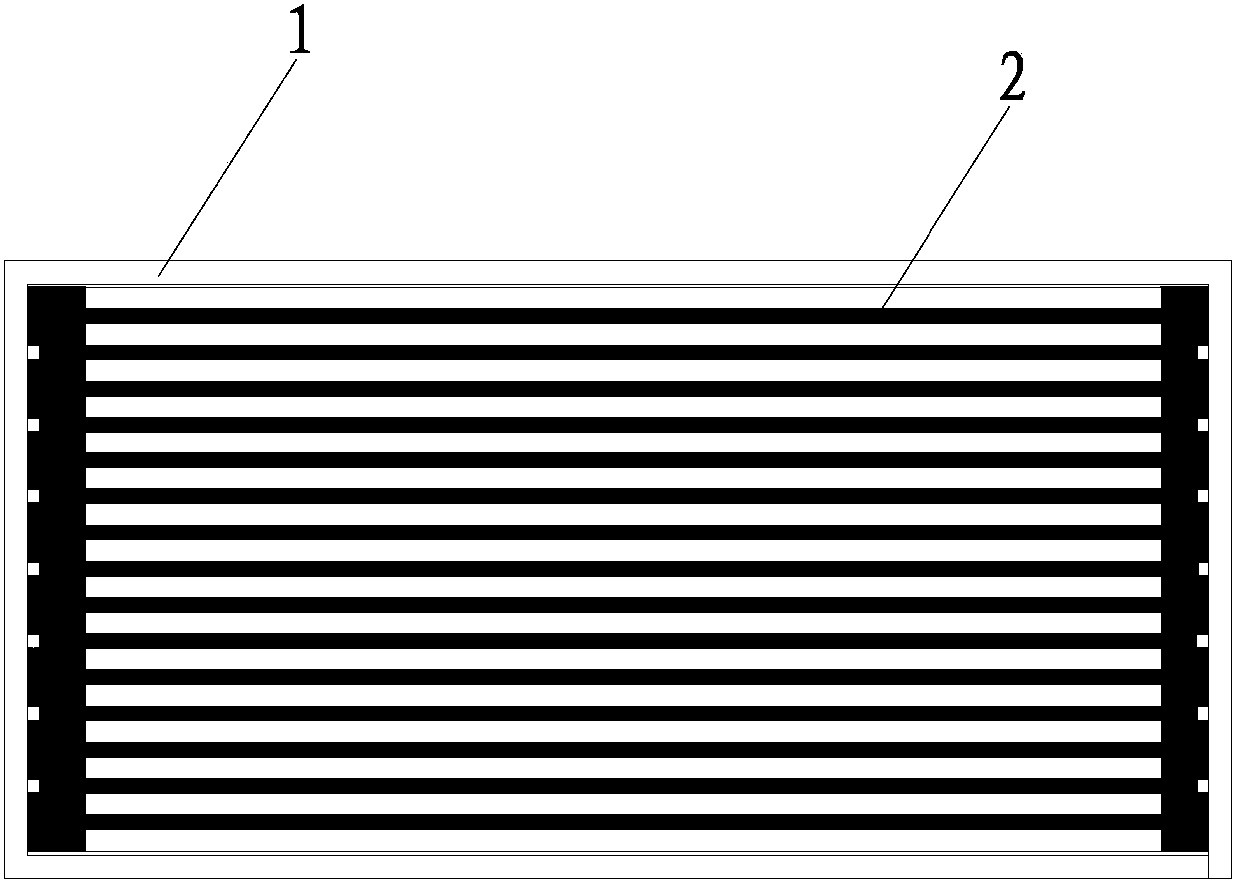

Image

Examples

Embodiment Construction

[0019] See figure 1 Shown: the present invention comprises wastewater treatment acoustic wave electro-oxidation process, and its steps are:

[0020] (1) The sewage enters the body of the ultrasonic sterilizer through the water inlet, and the ultrasonic wave with a control frequency above 40-120KHZ has the functions of cavitation, mixing, cracking, oxidation, pushing flow, sterilization, algae killing, cleaning, descaling, and ultrasonic wave on the sewage. Cavitation assists in sterilization and degradation of organic matter, so that water and oxidants can fully and evenly contact to achieve the purpose of degrading pollutants.

[0021] (2) Combining with oxidants to further carry out broad-spectrum sterilization. After bacteria, viruses, algae, and organisms in the water are subjected to a certain dose of oxidants, the DNA and RNA structures of their cells cannot be regenerated, and bacteria and viruses lose their ability to replicate themselves. To achieve the effect of ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com