Flexible plastic magnetic diaphragm material with regenerated plastics

A technology of recycled plastics and magnetic films, applied to the magnetism and coating of organic materials/organic magnetic materials, can solve the problems of difficulty in using recycled materials, water and soil pollution, waste of petrochemical resources, etc., and achieve industrial automation production , The processing method is simple and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

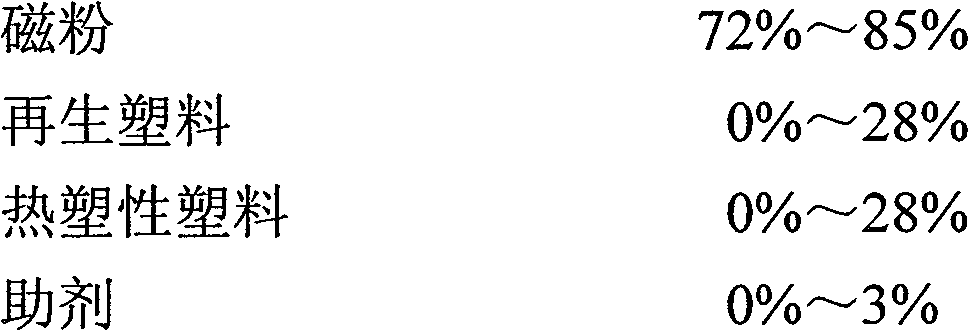

[0027] The raw material ratio is as follows

[0028] Iron powder 76.2%

[0029] Thermoplastics with added recycled plastic 23.5%

[0030] Auxiliary 0.3%.

[0031] The iron powder is iron oxide, the thermoplastic plastic added with recycled plastic is a mixture of polypropylene (PP) and recycled PP material in a ratio of 5:1, and the additives include antioxidant 1010 and antioxidant 168 , Lubricant stearic acid.

[0032] Step A: The raw materials are prepared into a mixture according to the above mass ratio.

[0033] Step B: Enter the mixture in step A from the feeding port of the extruder between the barrel and the screw of the extruder. The mixture is initially heated in the screw conveying section of the extruder, and at the same time conveyed to the compression section. After reaching the compression section, the mixture The temperature of the plastic and additives in the tank increases further and begins to melt, gradually forming a gelatinous mixture, which is convey...

Embodiment 2

[0036] The raw material ratio is as follows

[0037] Magnetic powder 81%

[0038] Thermoplastics with added recycled plastic 18.6%

[0039] Auxiliary 0.4%.

[0040] The anisotropic magnetic powder is strontium ferrite magnetic powder, the thermoplastic plastic added with recycled plastic is a mixture of polypropylene (PP) and recycled PP material in a ratio of 5:1, and the additives include antioxidant 1010 and antioxidant Oxygen 168, lubricant stearic acid, ultraviolet absorber.

[0041] Step A: The raw materials are prepared into a mixture according to the above mass ratio.

[0042] Step B: Add the mixture described in step A into the mixing device, under the double action of heating and pressure, the mixture is melted and plasticized, and then cooled to obtain a block material, and the block mixture is broken to obtain a tablet shape, powder billet. The temperature of the mixing device is controlled at 80°C to 230°C.

[0043] Step C: Add the pellets prepared in step B i...

Embodiment 3

[0045] The raw material ratio is as follows:

[0046] Magnetic powder 79%

[0047] Thermoplastics with added recycled plastic 20.4%

[0048] Auxiliary 0.6%

[0049] The isotropic magnetic powder is strontium ferrite magnetic powder, the thermoplastic plastic added with recycled plastic is a mixture of polypropylene (PP) and recycled PP material in a ratio of 4:1, and the additives include antioxidant 1010 and antioxidant Oxygen 168, lubricant stearic acid.

[0050] Step A: The raw materials are prepared into a mixture according to the above mass ratio.

[0051] Step B: Enter the mixture from the feeding port of the extruder between the barrel and the screw of the extruder, the mixture is initially heated in the screw conveying section of the extruder, and simultaneously conveyed to the compression section, and after reaching the compression section, the mixture is The temperature of the plastic and additives rises further and begins to melt, gradually forming a gelatinous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com