Nutrient solution matrix-free seedling raising and cultivating system and seedling raising method

A nutrient solution seedling cultivation and nutrient solution technology, which is applied to the nutrient solution substrate-free seedling cultivation system and the field of seedling cultivation, can solve the problems of limited use, difficulty in substrate deployment and nutrient regulation, and salinization of the substrate surface, and achieve the goal of improving uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

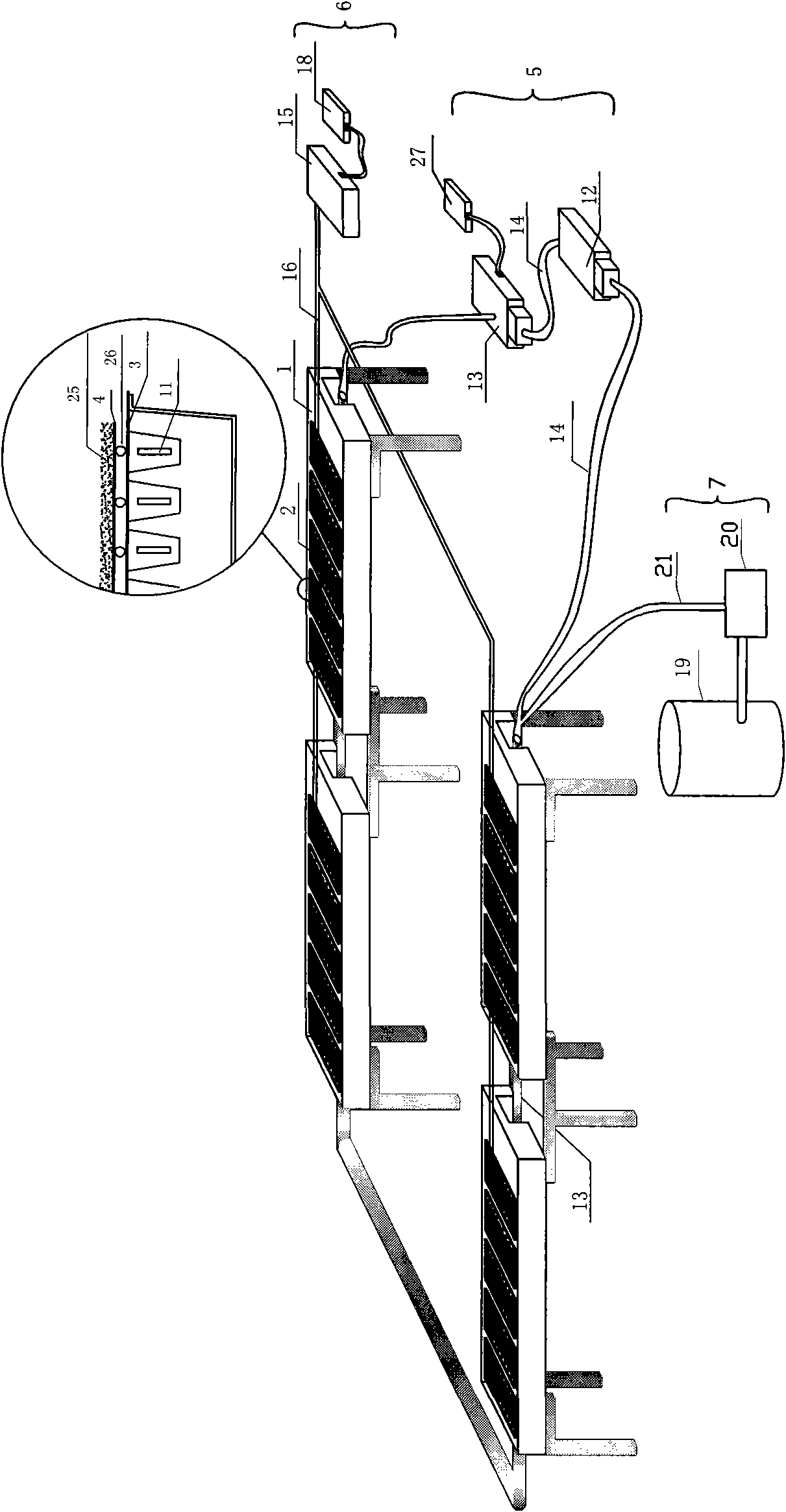

[0060] Example 1: Inflatable Nutrient Solution Substrate-free Seedling Cultivation System

[0061] figure 1 Shown is a schematic structural view of a preferred embodiment of the present invention. The nutrient solution substrate-free seedling cultivation system includes: nutrient solution seedling cultivation tank 1, seedling cultivation tray 2, sowing paper 3, covering paper 4, covering substrate 25, nutrient solution temperature Regulating system 5, nutrient solution oxygenation system 6 and nutrient solution supply system 7;

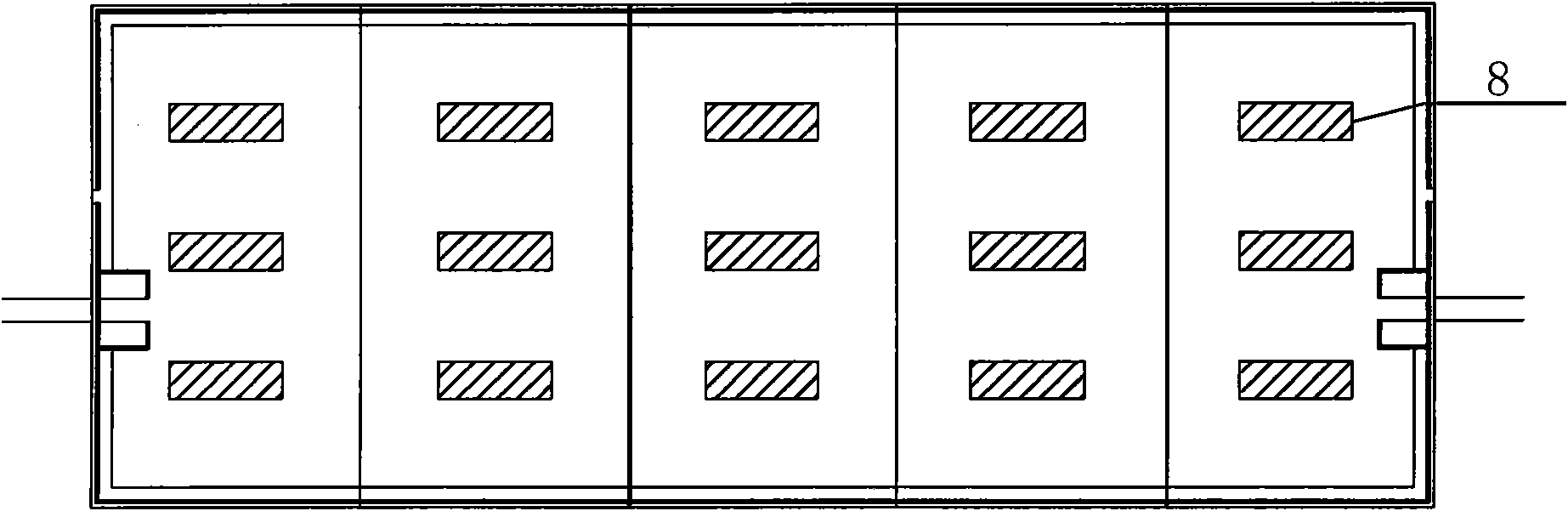

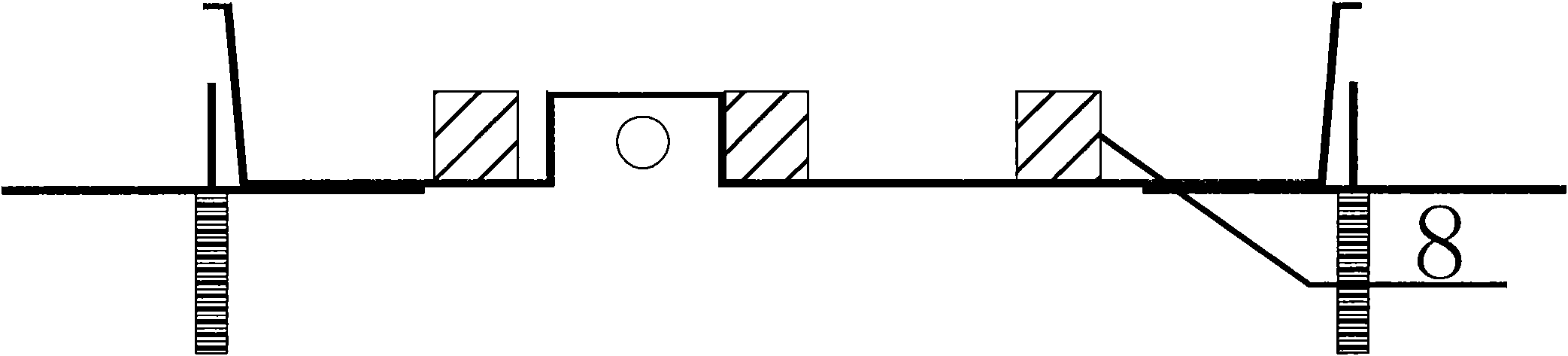

[0062] Such as figure 2 and image 3 As shown, the nutrient solution seedling cultivation tank 1 is a shallow dish-shaped hard plastic container with a height of 8.5 to 9.5 centimeters, containing water or nutrient solution. The width of the nutrient solution seedling-raising groove is determined according to the specification of the seedling-raising tray, and the length is the width of 5 seedling-raising grid trays, and support frame 8 is set at...

Embodiment 2

[0080] Example 2 Cucumber Seedling Cultivation without Substrate in Inflatable Nutrient Solution

[0081] (1) The seedling cultivation system described in application embodiment 1 carries out cucumber seedling cultivation, and cucumber seedling cultivation process comprises the steps:

[0082] A. inject cucumber special-purpose nutrient solution (its main element composition is shown in Table 1) in the nutrient solution seedling cultivation tank, the concentration of nutrient solution is full times amount, 6.5 centimeters of nutrient solution depth;

[0083] Table 1 Composition of special nutrient solution for cucumber

[0084]

[0085] b. Place the seedling raising tray with side openings on the nutrient solution seedling raising tank, cover it with sowing paper, and sow cucumber seeds directly on the sowing paper;

[0086] c. Cover the covering paper with water absorption and air permeability on the sowing paper loaded with seeds, and cover the wet perlite with a thickne...

Embodiment 3

[0109] Example 3 Circulating temperature-controlled nutrient solution substrate-free seedling cultivation system

[0110] The structures and functions of the nutrient solution seedling tank 1, the seedling tray 2, the sowing paper 3, the covering paper 4, the covering substrate 25 and the water level control valve 23 in the circulation temperature control type seedling raising system are the same as those in the first embodiment.

[0111] Such as Figure 7 and Figure 8 Shown, the circulation temperature control type seedling raising system also comprises nutrient solution circulation temperature control system, and it is by nutrient solution pool 22, transfusion pipeline 31, circulation device 24, the timer 30 that regulates water pump operation, temperature control device 32 and heating, cooling The device 33 is composed. The nutrient solution pool 22 stores the prepared nutrient solution working solution, and the nutrient solution pool 22 is equipped with heating and cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com