Preparation method of fermented vegetable protein

A plant protein and mineral technology, applied in the field of fermented plant protein preparation, can solve the problem that cellulose cannot be effectively removed, and achieve low cost, environmental protection and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

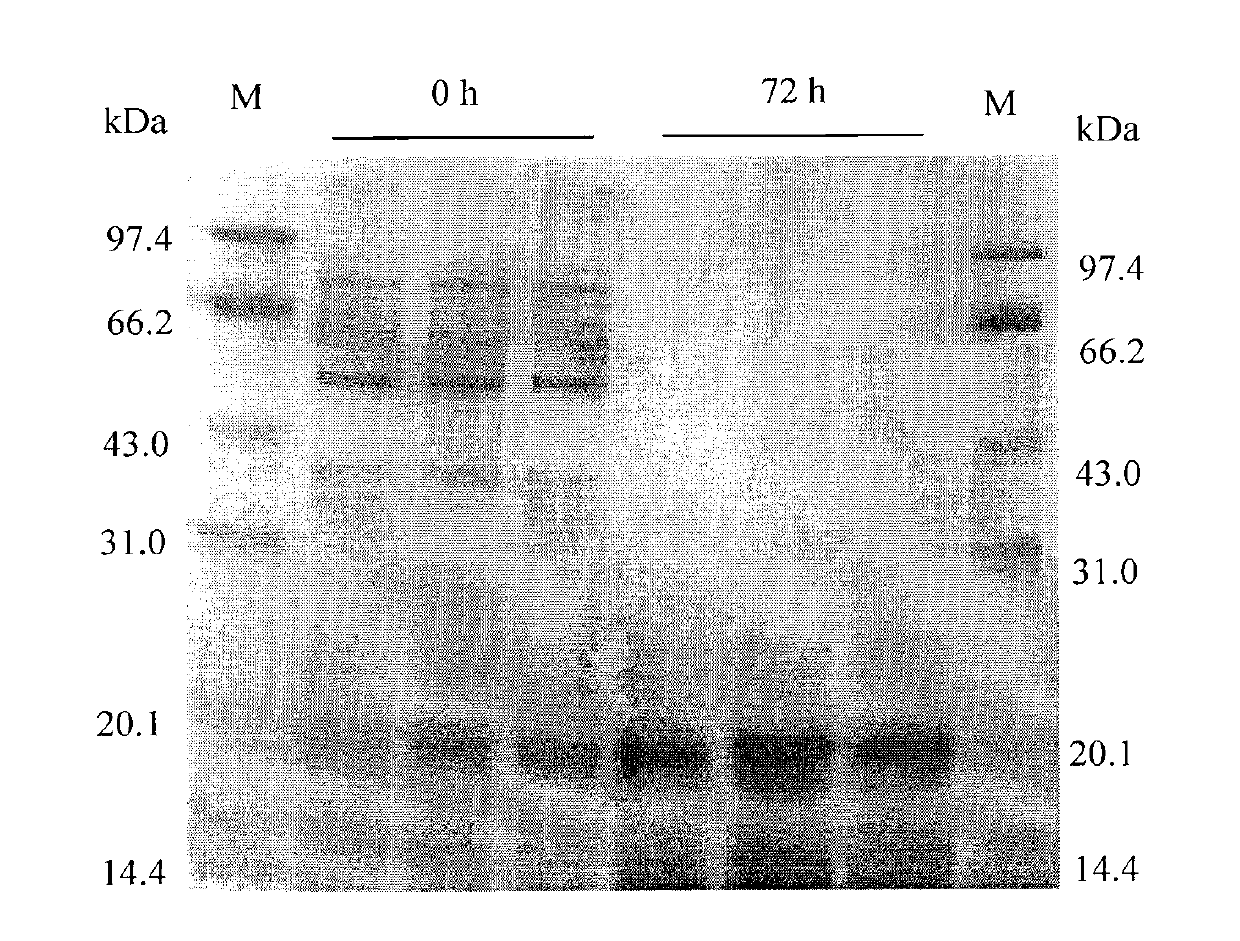

Examples

Embodiment 1

[0021] The present embodiment selects rapeseed meal as raw material.

[0022] (1) Crush the rapeseed meal, pass through a 40-mesh sieve, mix well, weigh 50g of rapeseed meal powder and put it into CO 2 Gas purged 500ml anaerobic fermentation bottle.

[0023] (2) When slaughtering ruminants such as cattle, sheep, deer, etc., quickly separate the rumen without opening the rumen, turn the rumen upside down several times, and mix the rumen contents evenly. Then cut the rumen with scissors, the opening of the rumen should not be too large, and it is inconvenient to collect the rumen contents if the opening is too large. used CO 2 The gas-purged wide-mouth collection bottle is used to collect the contents of the rumen, placed in a water bath at 39±0.5°C, and filtered with two layers, four layers, and six layers of gauze in sequence. The filtration should be as fast as possible to maintain the vitality of microorganisms. At the same time, CO is continuously passed into the obtaine...

Embodiment 2

[0033] In this example, soybean meal was used as raw material.

[0034] (1) Peel and crush the soybean meal, pass through a 40-mesh sieve, mix well, weigh 50g of soybean meal powder and put it into CO 2 Gas purged 500ml anaerobic fermentation bottle.

[0035] (2) When slaughtering ruminants such as cattle, sheep, deer, etc., quickly separate the rumen without opening the rumen, turn the rumen upside down several times, and mix the rumen contents evenly. Then cut the rumen with scissors, the opening of the rumen should not be too large, and it is inconvenient to collect the rumen contents if the opening is too large. used CO 2 The gas-purged wide-mouth collection bottle is used to collect the contents of the rumen, placed in a water bath at 39±0.5°C, and filtered with two layers, four layers, and six layers of gauze in sequence. The filtration should be as fast as possible to maintain the vitality of microorganisms. At the same time, CO is continuously passed into the obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com