Directional solidifying crystallization method of metal alloy magnet and device for implementing same

A technology for directional solidification of metal alloys, applied in the field of directional solidification and crystallization of metal alloy magnets and devices implementing the method, which can solve the problems of uneven cooling, large temperature difference between the surface and core of metal alloy magnets, and the degree of crystal orientation needs to be improved. problem, to achieve the effect of overcoming the temperature gradient is too small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

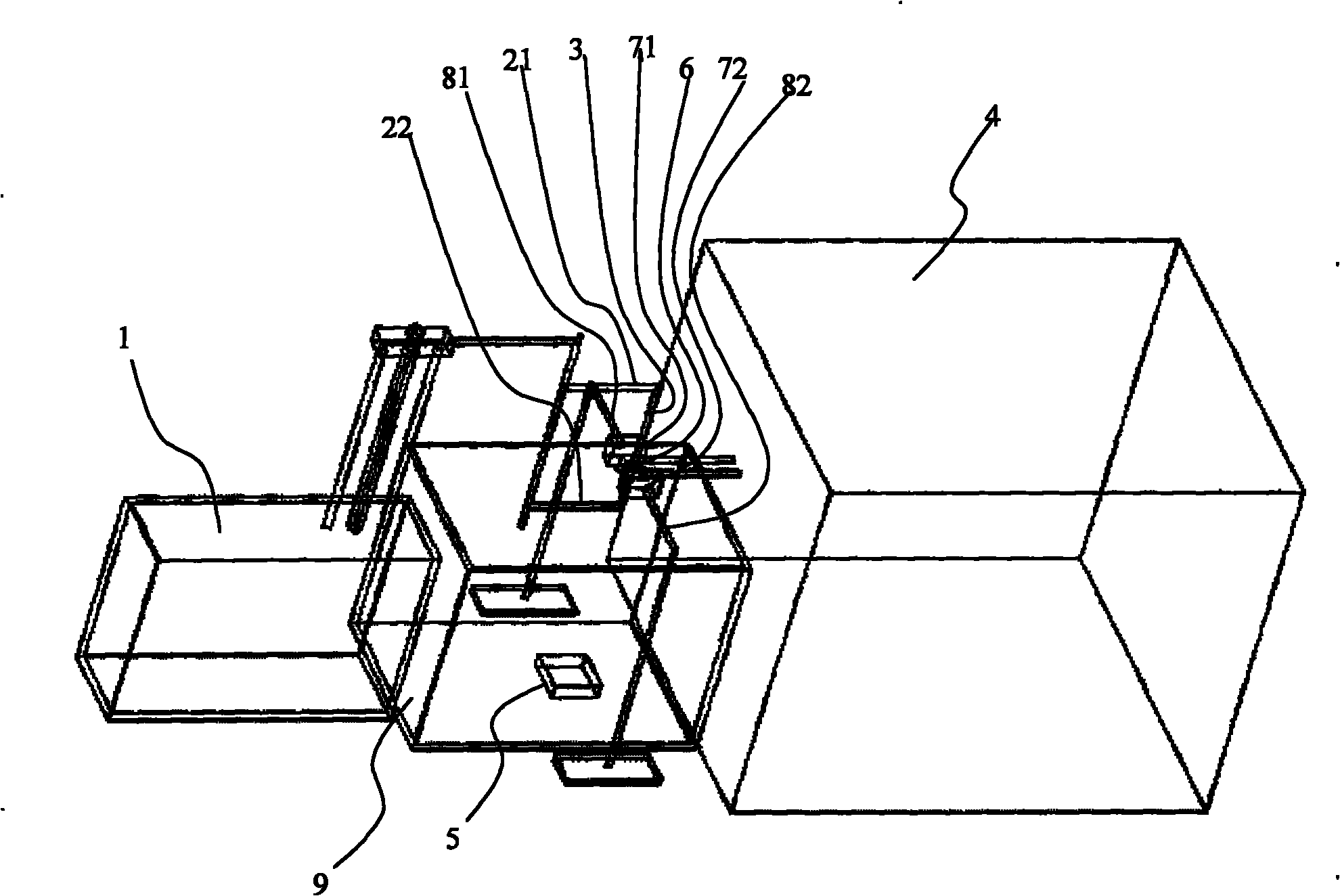

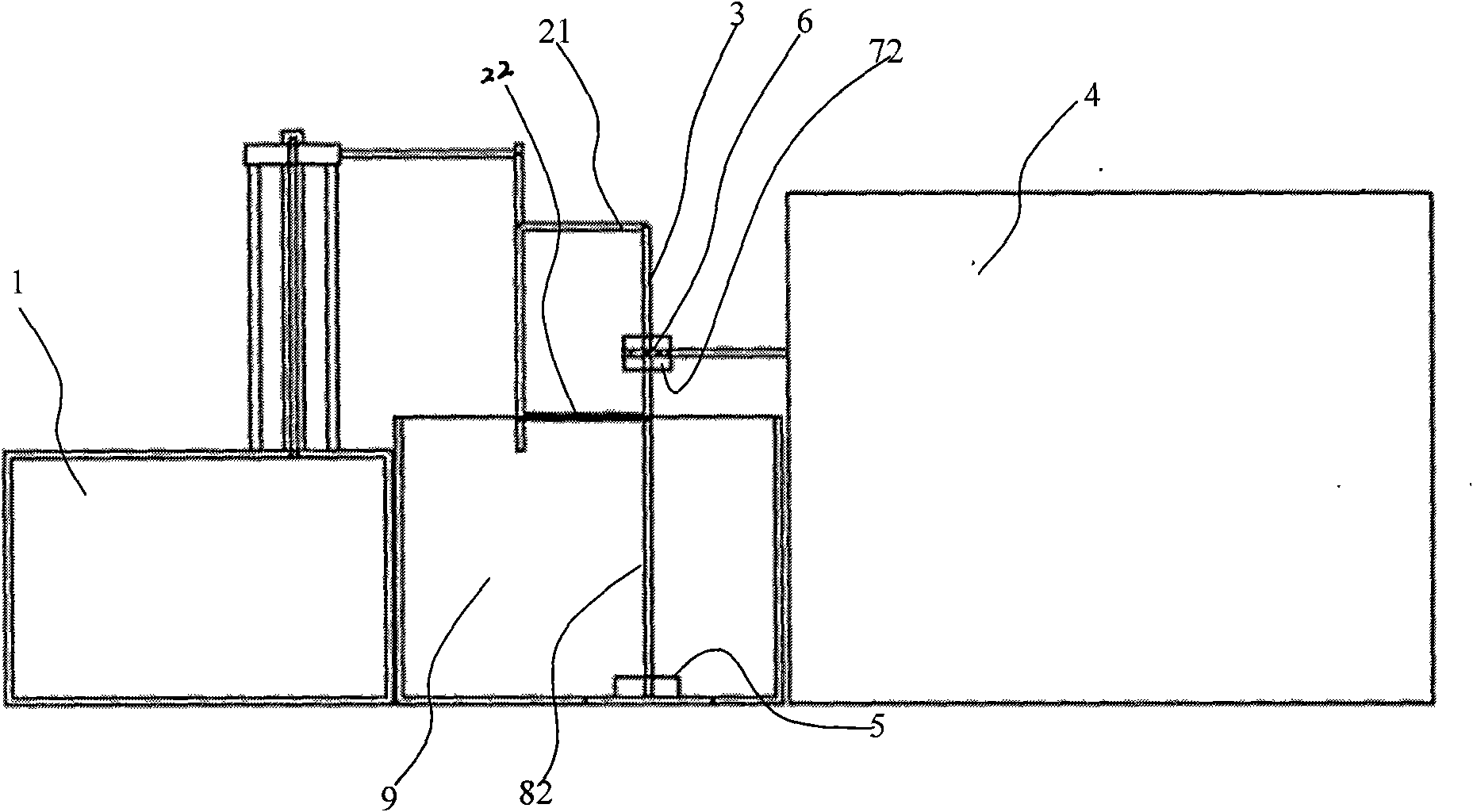

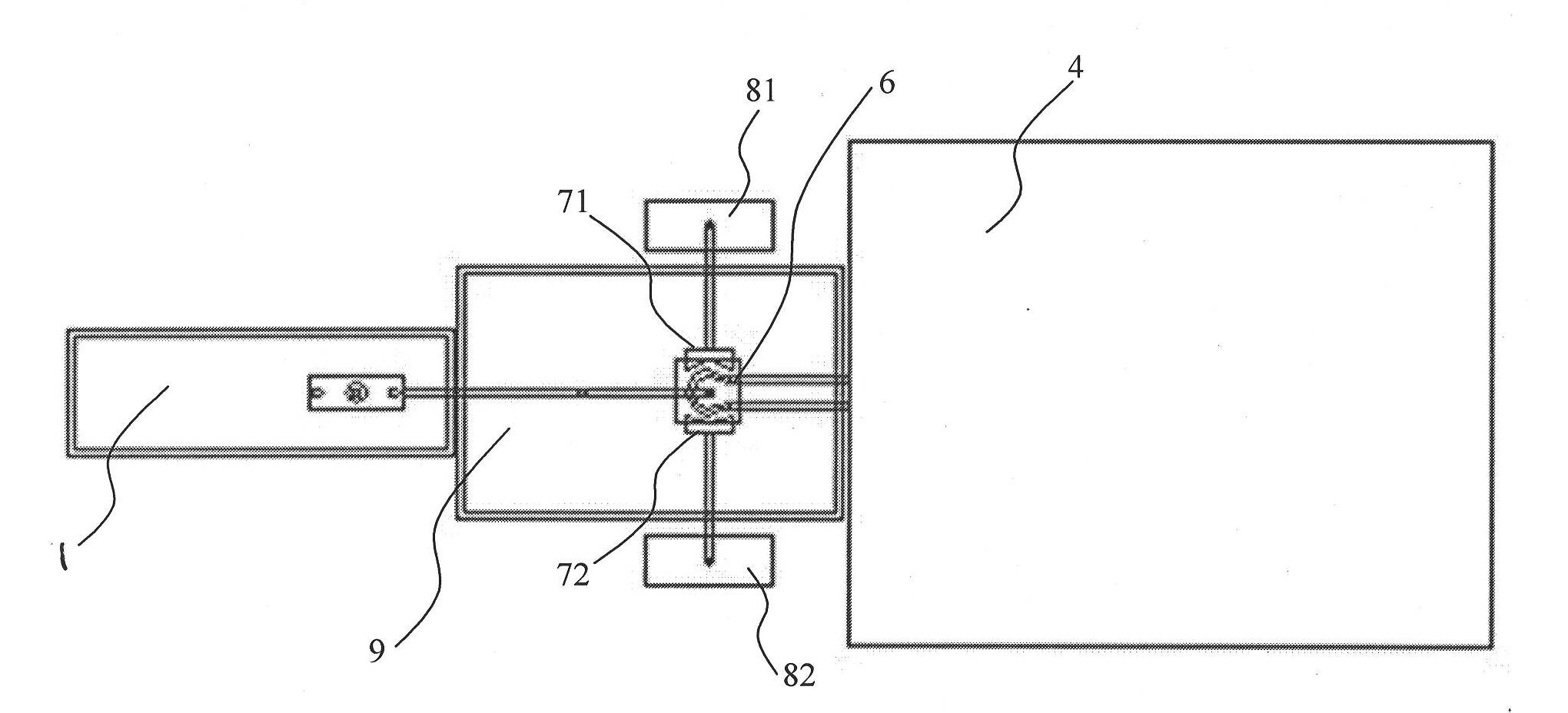

[0034] use Figure 1 to Figure 3 The device for implementing the method of directional solidification and crystallization of metal alloy magnets as shown, performs directional solidification and crystallization of a rod-shaped alnico magnet with a diameter of 10 mm and a length of 300 mm, wherein the current of the high-frequency induction power supply is 60A, and the lifting equipment is The speed of 2 mm / min moves downward, the cooling body is liquid cooling water, the distance from the induction coil to the cooling water surface is 60 mm, the magnetic induction of the transverse magnet on the periphery of the induction coil 6 is 2T, and the longitudinal magnet at the bottom of the cooling tank The magnetic induction intensity is 2T.

[0035] The transmission electron microscope picture of the above-mentioned alnico magnet after directional solidification and crystallization, that is, the TEM picture is as follows Figure 4 As shown, it can be seen from the figure that the ...

Embodiment 2

[0037] use Figure 1 to Figure 3The device for implementing the method of directional solidification and crystallization of metal alloy magnets shown in the figure is to carry out directional solidification and crystallization of a bar-shaped iron-chromium alloy magnet with a diameter of 8 mm and a length of 200 mm. The cooling body is liquid cooling water, the distance from the induction coil to the liquid surface of the cooling water is 40mm, the magnetic induction of the transverse magnet on the periphery of the induction coil is 2T, and the magnetic induction of the longitudinal magnet at the bottom of the cooling tank The strength is 2T.

[0038] The TEM image of the above iron-chromium alloy magnet after directional solidification and crystallization is similar to Figure 4 As shown, compared with the existing technology, after the directional solidification and crystallization of the device, the grain orientation of the iron-chromium alloy magnet is promoted, the degre...

Embodiment 3

[0040] use Figure 1 to Figure 3 The device for implementing the method of directional solidification and crystallization of metal alloy magnets shown in the figure is to carry out directional solidification and crystallization of rod-shaped nickel-niobium alloy magnets with a diameter of 6 mm and a length of 300 mm. The cooling body is liquid cooling water, the distance from the induction coil to the cooling water surface is 70mm, the magnetic induction of the transverse magnet on the periphery of the induction coil is 2T, and the magnetic induction of the longitudinal magnet at the bottom of the cooling tank The strength is 2T.

[0041] The TEM image of the above nickel-niobium alloy magnet after directional solidification and crystallization is similar to Figure 4 As shown, compared with the existing technology, after the directional solidification and crystallization of the device, the grain orientation of the nickel-niobium alloy magnet is promoted, the crystal orientat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com