Reagent for cutting sulfydryl-containing peptides from resins and cutting method

A thiol polypeptide and peptide-cutting reagent technology is applied in the field of reagents for cutting thiol-containing peptides from resins, which can solve the problems of high price and foul odor, and achieve the effects of high price, reduction of three wastes, and reduction of environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

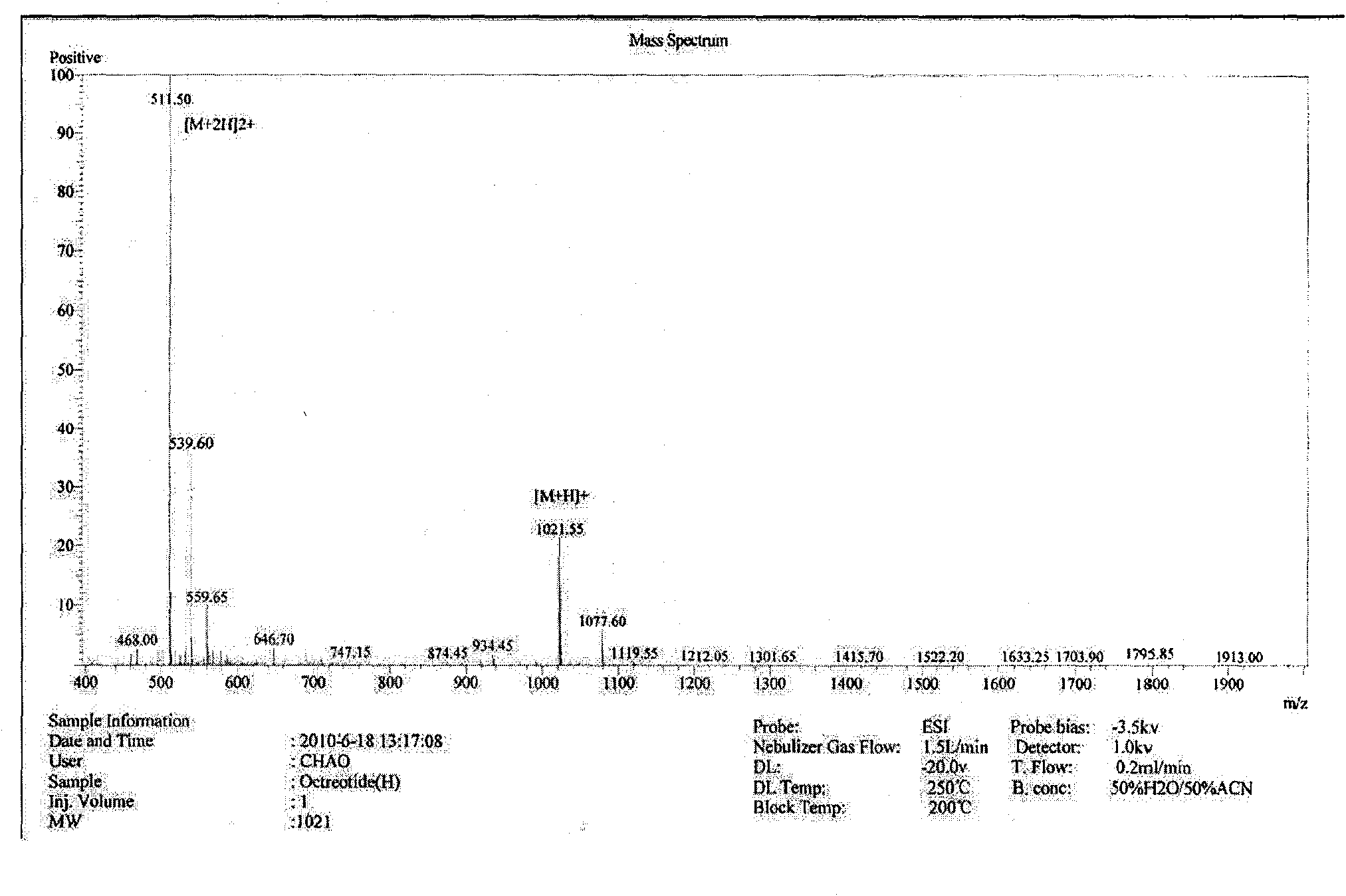

[0050] 1g of octreotide resin containing protective groups {D-Phe-Cys(Trt)-Phe-D-Trp-Lys(Boc)-Thr(tBu)-Cys(Trt)-Th(tBu)-ol-resin, degree of substitution 0.404mmol / g, provided by Shanghai Xuxin Chemical Technology Co., Ltd.}, added to the peptide cutting reagent {trifluoroacetic acid 9.0ml, triisopropylsilane 4ml, mercaptopropionic acid 3ml, phenol 2ml, water 1ml cooled to 5 °C }, at room temperature, magnetically stirred for 1 hour. Filter under reduced pressure with a sand core funnel, and wash the resin twice with 5 ml of trifluoroacetic acid. The resin was discarded, the mother liquor and the washing solution were combined, 80ml of cold diethyl ether was added, and after standing at 5°C for 1.5 hours, a white precipitate precipitated out. The white precipitate was collected by filtration, and the precipitate was repeatedly washed five times with 10 ml of anhydrous ether. Drained, and dried to constant weight under a vacuum environment of phosphorus pentoxide to obtain 410 ...

Embodiment 2

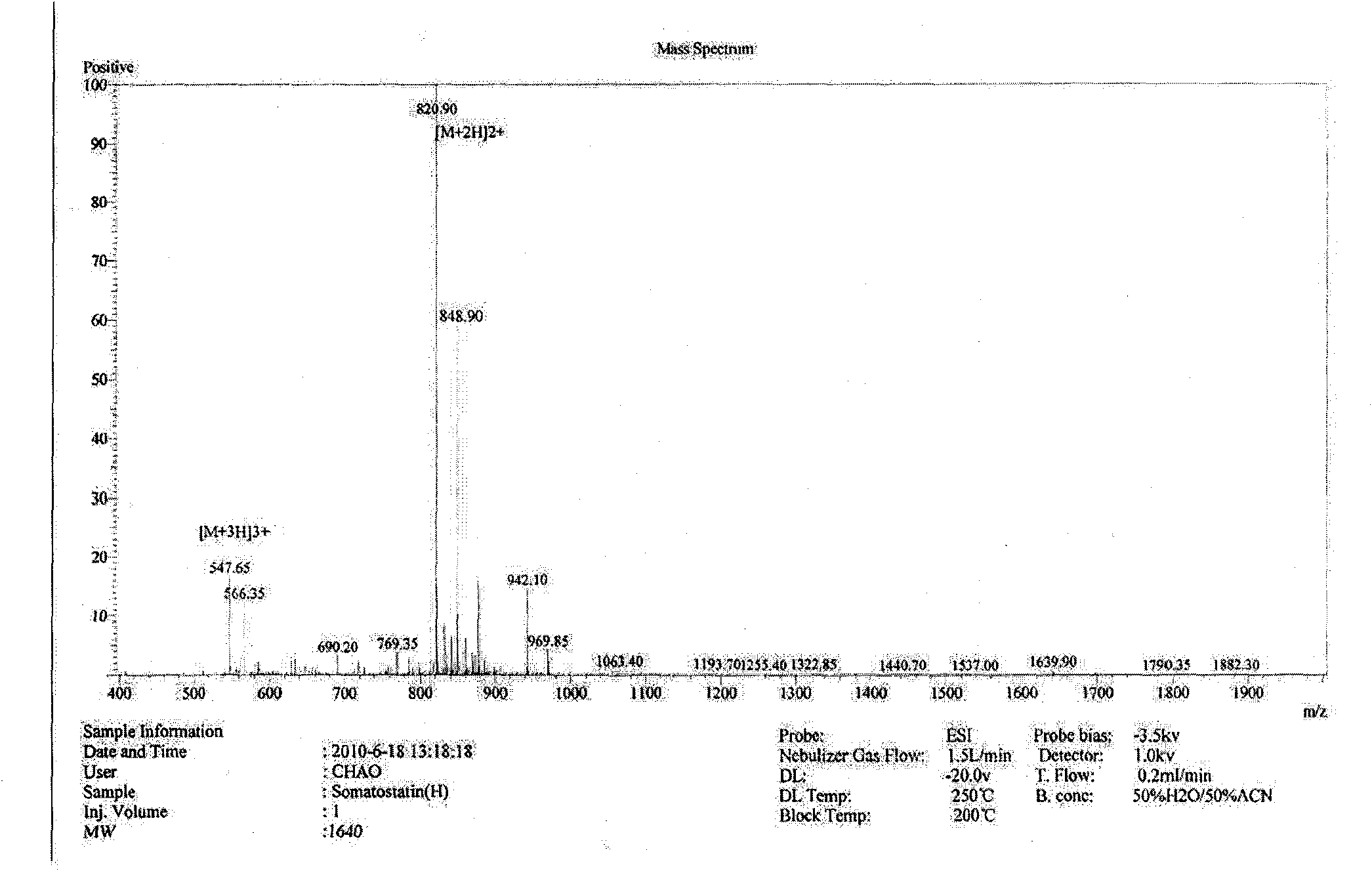

[0053] 1g of somatostatin peptide resin {Ala-Gly-Cys(Trt)-Lys(Boc)-Asn(Trt)-Phe-Phe-Trp-Lys(Boc)-Thr(tBu)-Phe-Thr (tBu)-Ser(tBu)-Cys(Trt)-resin, the degree of substitution is 0.312mmol / g, provided by Shanghai Xuxin Chemical Technology Co., Ltd}, add the peptide cutting reagent {trifluoroacetic acid 9.0ml, cooled to 5 °C, Triisopropylsilane 4ml, sodium mercaptopropionate 3ml, phenol 2ml, water 1ml}, at room temperature, magnetically stirred for 2 hours. Filter under reduced pressure with a sand core funnel, and wash the resin twice with 5 ml of trifluoroacetic acid. Discard the resin, combine the mother liquor with the washing solution, add about 80ml of cold diethyl ether, and let it stand at 7°C for 0.5 hours, a white precipitate precipitates out; collect the white precipitate by filtration, wash the precipitate with 10ml of anhydrous ether five times, and drain it. Phosphorus oxide was vacuum-dried to constant weight to obtain 510 mg (0.311 mmol) of the crude product of red...

Embodiment 3

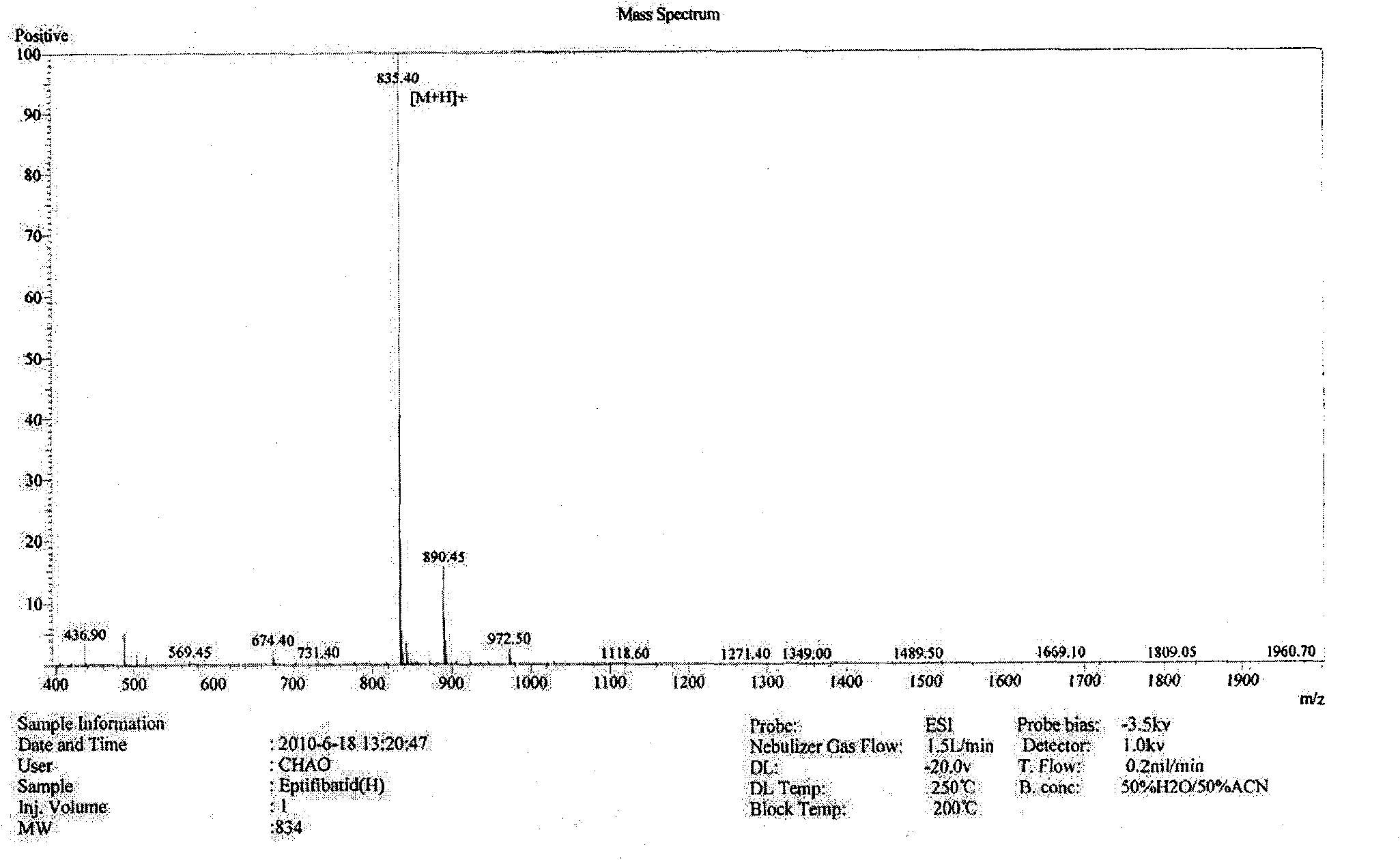

[0056] 1g of eptifibatide resin {Mpa(Trt)-Har(Pbf)-Gly-Asp(OtBu)-Trp-Pro-Cys(Trt)-resin containing protective groups, with a degree of substitution of 0.560mmol / g, Shanghai Xu Provided by New Chemical Technology Co., Ltd.}, add peptide cutting reagent {trifluoroacetic acid 9.0ml, triisopropylsilane 4ml, thioglycolic acid 3ml, phenol 2ml, water 1ml} cooled to 5°C, and stir magnetically for 3 hours at room temperature. Filter under reduced pressure with a sand core funnel, and wash the resin twice with 5 ml of trifluoroacetic acid. Discard the resin, combine the mother liquor with the washing solution, add 80ml of cold diethyl ether, and let it stand at 5°C for 1 hour, a white precipitate precipitates out; collect the precipitate by filtration, wash the precipitate with 10ml of anhydrous ether repeatedly five times, drain it, and dry it with diethyl ether Phosphorus was vacuum-dried to obtain 466 mg (0.558 mmol) of the crude product of reduced eptifibatide, the yield of cleaved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com