Method for preparing boards from carboxymethyl starch serving as binding agent and waste plant fibers

A technology of carboxymethyl starch and plant fiber, which is applied in the field of home decoration, furniture manufacturing and packaging, to reduce consumption, benefit the environment and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

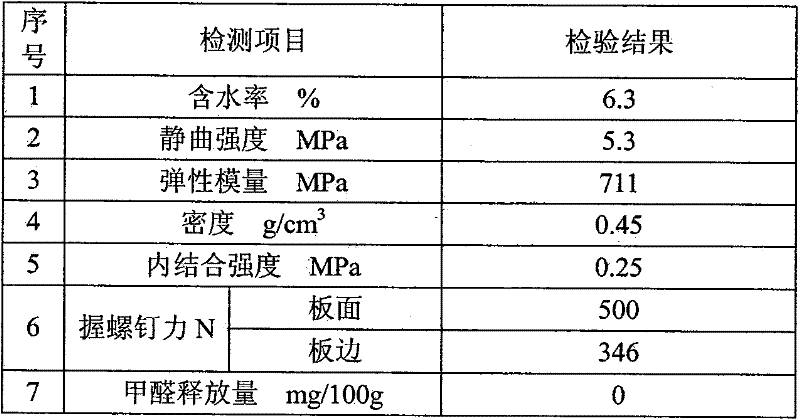

[0007] Embodiment 1: when making size is 210mm * 210mm * 18mm board material, needs to use carboxymethyl starch 93.6g, tap water 1080g by weight ratio, is heated to 50-90 ℃ and carboxymethyl potato starch is all dissolved, adds 360g corrugated paper dust powder After that, stir fully, put it into the mold after stirring evenly, and make a plate after forming, polishing, demoulding and drying. The inspection results of the plates prepared in this embodiment are shown in the table below.

[0008]

Embodiment 2

[0009] Embodiment 2: when making size is 210mm * 210mm * 18mm board material, need to use carboxymethyl starch 88g, tap water 1000g by weight ratio, be heated to 50-90 ℃ and carboxymethyl potato starch is all dissolved, after adding 380g corrugated paper dust powder Stir well, put it into a mold after stirring evenly, and make a plate after forming, polishing, demoulding and drying.

Embodiment 3

[0010] Example 3: When making a plate with a size of 210mm × 210mm × 18mm, it is necessary to use 80g of carboxymethyl starch and 940g of tap water according to the weight ratio, and heat to 50-90°C to completely dissolve the carboxymethyl potato starch. After adding 400g of wheat straw powder Stir well, put it into a mold after stirring evenly, and make a plate after forming, polishing, demoulding and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com