Alternating current servo driver capable of realizing energy feedback

A technology of AC servo and energy feedback, which is applied in the direction of AC motor control, reversible conversion equipment, and AC network to reduce harmonics/ripples, etc. It can solve the problems of high price, increased processing links, and increased costs. Achieving low-cost, undemanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

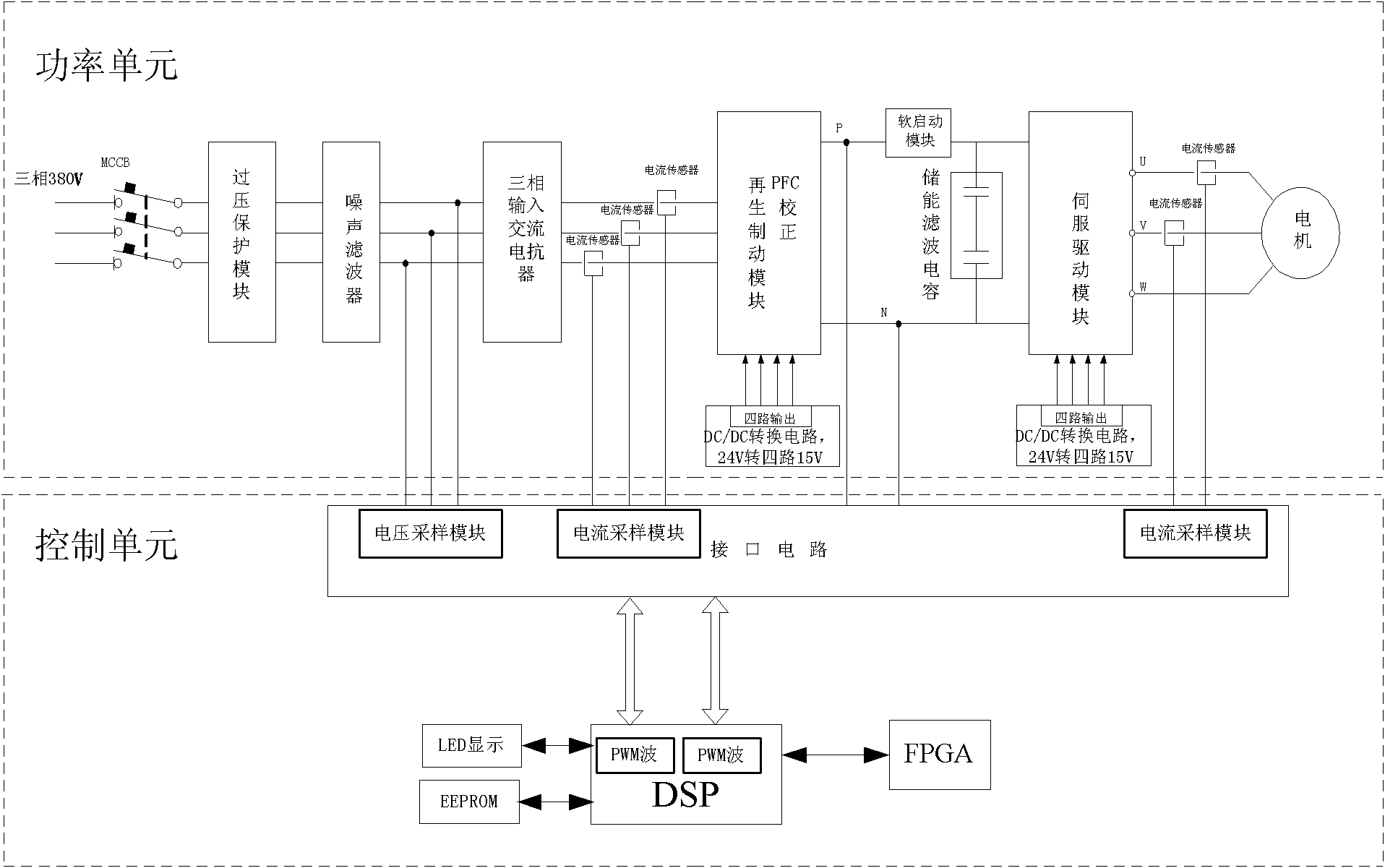

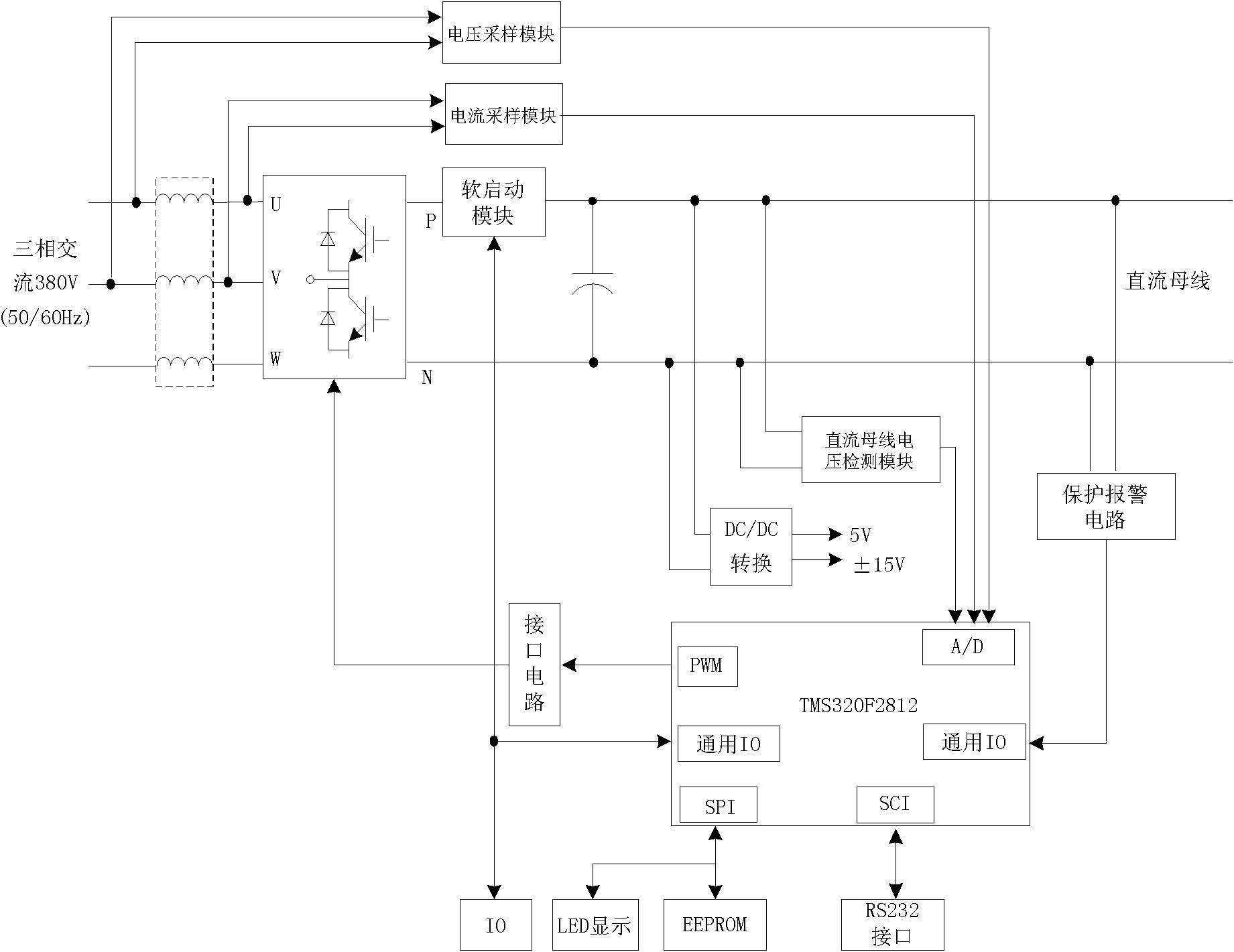

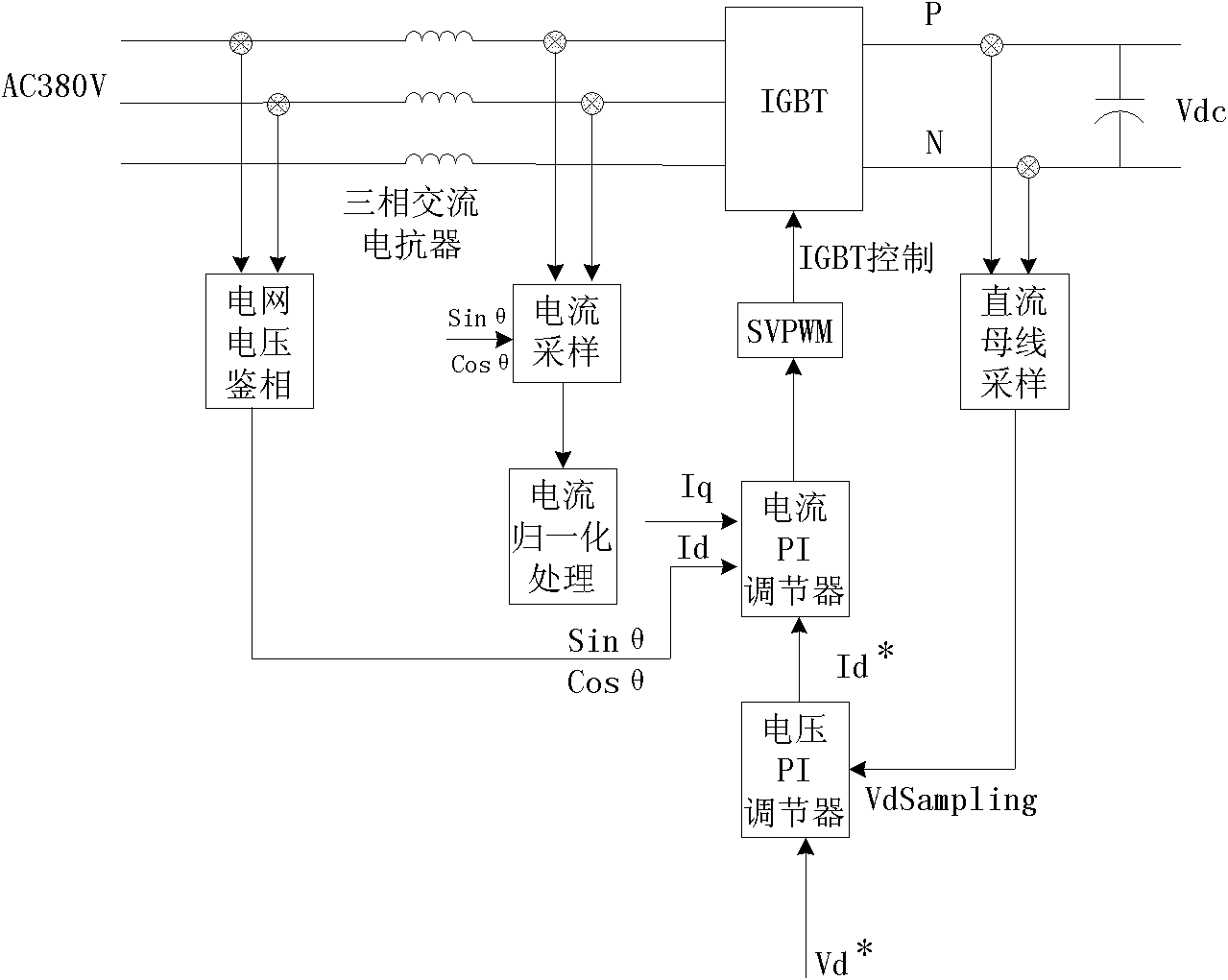

[0027] In this embodiment, an AC servo driver that can realize energy feedback, such asfigure 1 or figure 2 As shown, it includes a power unit and a control unit. The power unit includes an overvoltage protection module, a noise filter, a three-phase input AC reactor, a PFC correction regenerative braking module and a servo drive module connected in sequence, an overvoltage protection module, and a noise filter Inverter, three-phase input AC reactor and PFC correction regenerative braking module constitute the servo power supply, the input terminal of the overvoltage protection module is connected to the three-phase AC power supply, the output terminal of the servo drive module is connected to the motor, and the PFC correction regenerative braking module is connected to the There is also a soft start module and an energy storage filter capacitor between the servo drive modules; the control unit includes a digital signal processor, an interface circuit module, a DC bus voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com