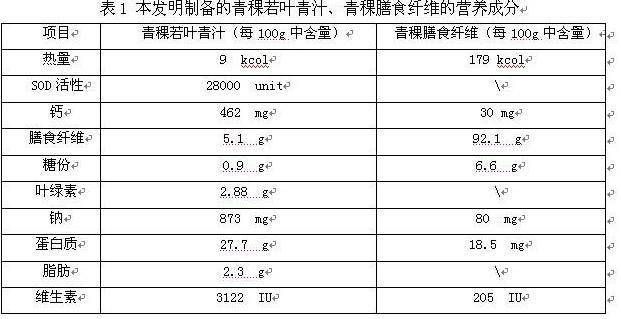

Preparation method for simultaneously extracting Tibet barley serum and Tibet barley dietary fiber

A dietary fiber and highland barley technology, applied in the field of bioengineering, can solve the problems of pesticide residue hazards, increase the possibility of pesticides, and easy to destroy vitamins, so as to avoid the loss of food nutrients, ensure green and non-polluting, and prevent environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation process route of the present invention mainly comprises:

[0020] 20-30cm highland barley seedlings → pretreatment → sterilized and soaked at 80°C → pressed dry → supercritical extraction → to obtain the extracted components →

[0021]

[0022] Preparation method of the present invention, concrete process is as follows:

[0023] (1) Harvest the young highland barley seedlings that grow to 20-30 cm from the Qinghai-Tibet Plateau, and transport them to the production workshop within 30 minutes after harvesting. After removing impurities, wash with water. The washed young highland barley leaves are soaked in 80° C. pure water for 3 minutes to kill enzymes and sterilize. After taking it out, rinse it with pure water, cool it down to room temperature quickly, and then dry it with a pressure dryer.

[0024] (2) The dried highland barley leaves are put into SFE equipment for supercritical extraction, and the extracted components containing green juice of ...

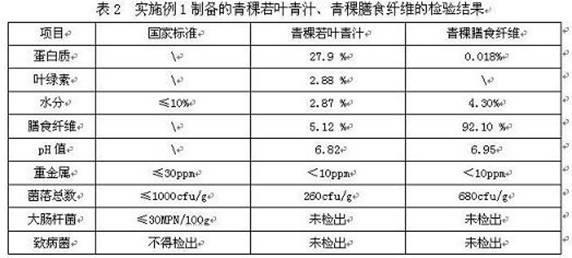

Embodiment 1

[0030] Harvest 20-30 cm highland barley tender seedlings in 1000 square meters of farmland, and get 243kg highland barley tender leaves, which will be transported to the production workshop within 30 minutes after harvesting. Remove impurities such as dead leaves and weeds, wash them repeatedly with tap water, and then rinse with pure water.

[0031]The washed young highland barley leaves are soaked in 80° C. pure water for 3 minutes to kill enzymes and sterilize. Rinse it with pure water after taking it out, cool it down to room temperature quickly, and then dry it with a pressure dryer to obtain 123.3 kg of dried material. The dried barley leaves enter the SFE equipment for supercritical extraction, and 37.4 kg of extract components containing barley grass leaf juice and 81.2 kg of extract components containing dietary fiber are collected.

[0032] Turn on the cooling brine of the colloidal grinder, add 16.8kg of pure water to the extracted components of 37.4kg of highland ...

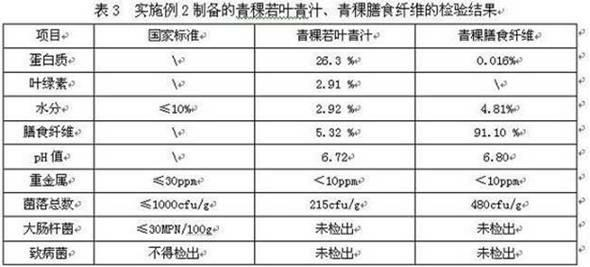

Embodiment 2

[0037] About 20 days after fertilization and irrigation on the farmland that has been harvested once, the regenerated young barley leaves have reached the requirement of 20-30 cm. Harvesting the regenerated young highland barley seedlings of 1000 square meters of farmland yielded 128 kg of young highland barley leaves. Shipped to the production workshop within minutes. Remove impurities such as dead leaves and weeds, rinse with tap water repeatedly, and then rinse with pure water.

[0038] The washed young highland barley leaves are soaked in 80° C. pure water for 3 minutes to kill enzymes and sterilize. After taking it out, rinse it with pure water, cool it down to room temperature rapidly, and then dry it with a pressure dryer to obtain 64.3 kg of pressed dry material. The dried barley leaves were put into SFE equipment for supercritical extraction, and 19.6 kg of extract components containing green barley juice and 41.2 kg of extract components containing dietary fiber wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com