Method for synthesizing silicon substrate molecular sieve by using copper amine complex as template agent

A silicon-based molecular sieve and complex technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of not being large-pore mordenite, restricting industrial application, high price, etc., and achieving low cost, simple and easy method, high cost. The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Preparation of CHA sample (Si / Al=8.8)

[0032] First, dissolve 0.514 grams of sodium aluminate solid in 4.722 grams of water, then add 1.149 grams of copper sulfate pentahydrate solid, and after stirring for half an hour, add 1.07 grams of tetraethylenepentamine dropwise to the above system, and then add 0.38 gram of sodium hydroxide solid, after stirring for half an hour, add 3.6 milliliters of 31.5% silica sol to the above system, after stirring for two to three hours, put it into a polytetrafluoroethylene-lined steel reactor, and react at 140 degrees Two to six days. The chemical ratio of the system is as follows: 3.41Na 2 O: 1.0Al 2 o 3 : 10SiO 2 : 200H 2 O:2.0Cu-R (wherein R:Cu=1:1). After the reaction is completed, the obtained product is fully washed with deionized water, and dried at 100 degrees for more than 12 hours.

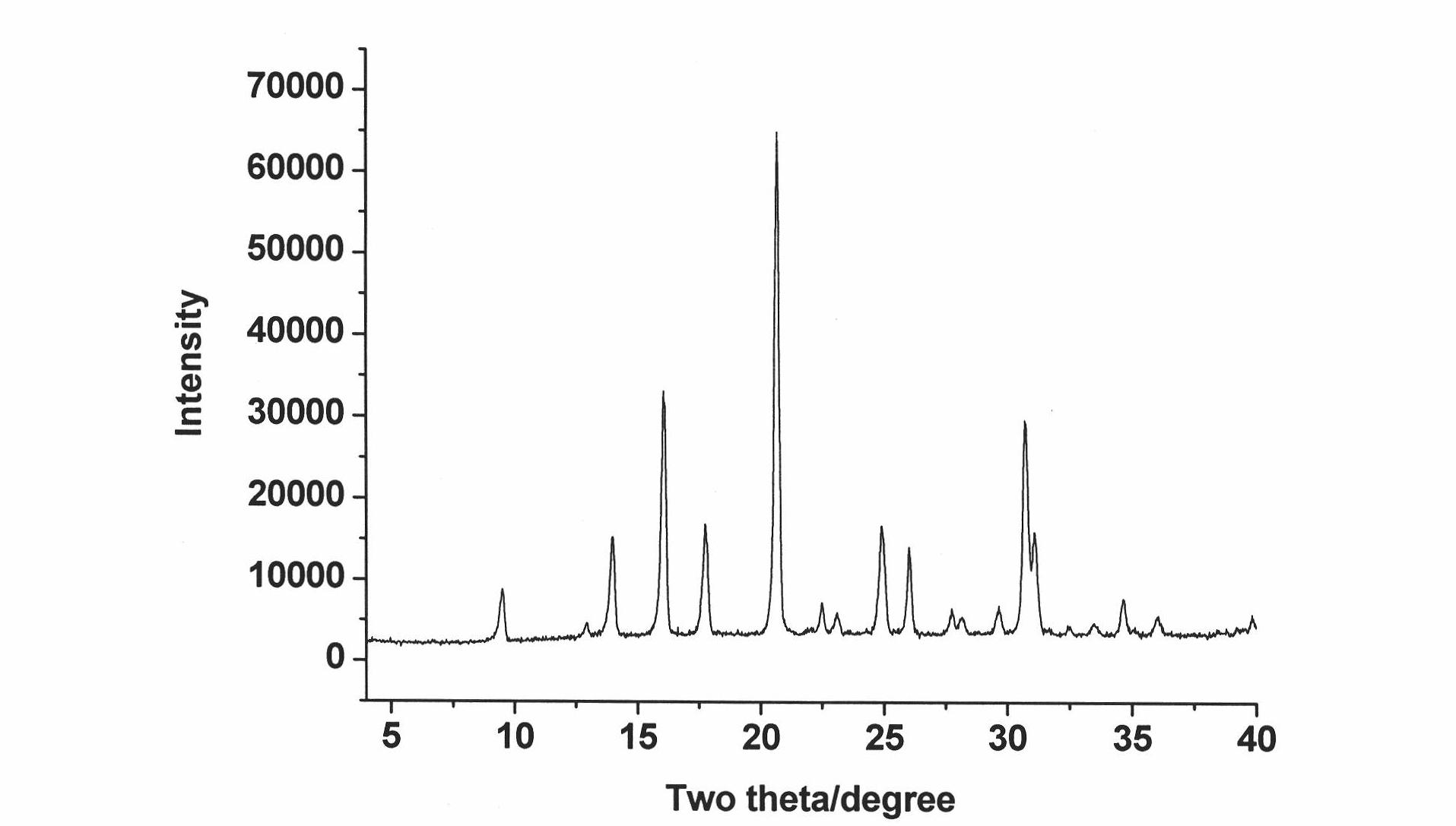

[0033] attached figure 1 According to the XRD characterization results of the product, it can be seen that the product ha...

Embodiment 2

[0035] Embodiment 2: Preparation of CHA sample (Si / Al=20)

[0036] The addition sequence and stirring time of gel preparation are the same as in Example 1. The difference is that the solid amount of sodium aluminate is 0.129 grams, and the solid amount of sodium hydroxide is 0.45 grams. The chemical ratio of the system is: 8.7Na 2 O: 1.0Al 2 o 3 : 30SiO 2 : 200H 2 O: 6.0Cu-R (wherein R: Cu = 1: 1), react at 140 degrees for four to ten days. After the reaction is completed, the obtained product is fully washed with deionized water, and dried at 100 degrees for more than 12 hours.

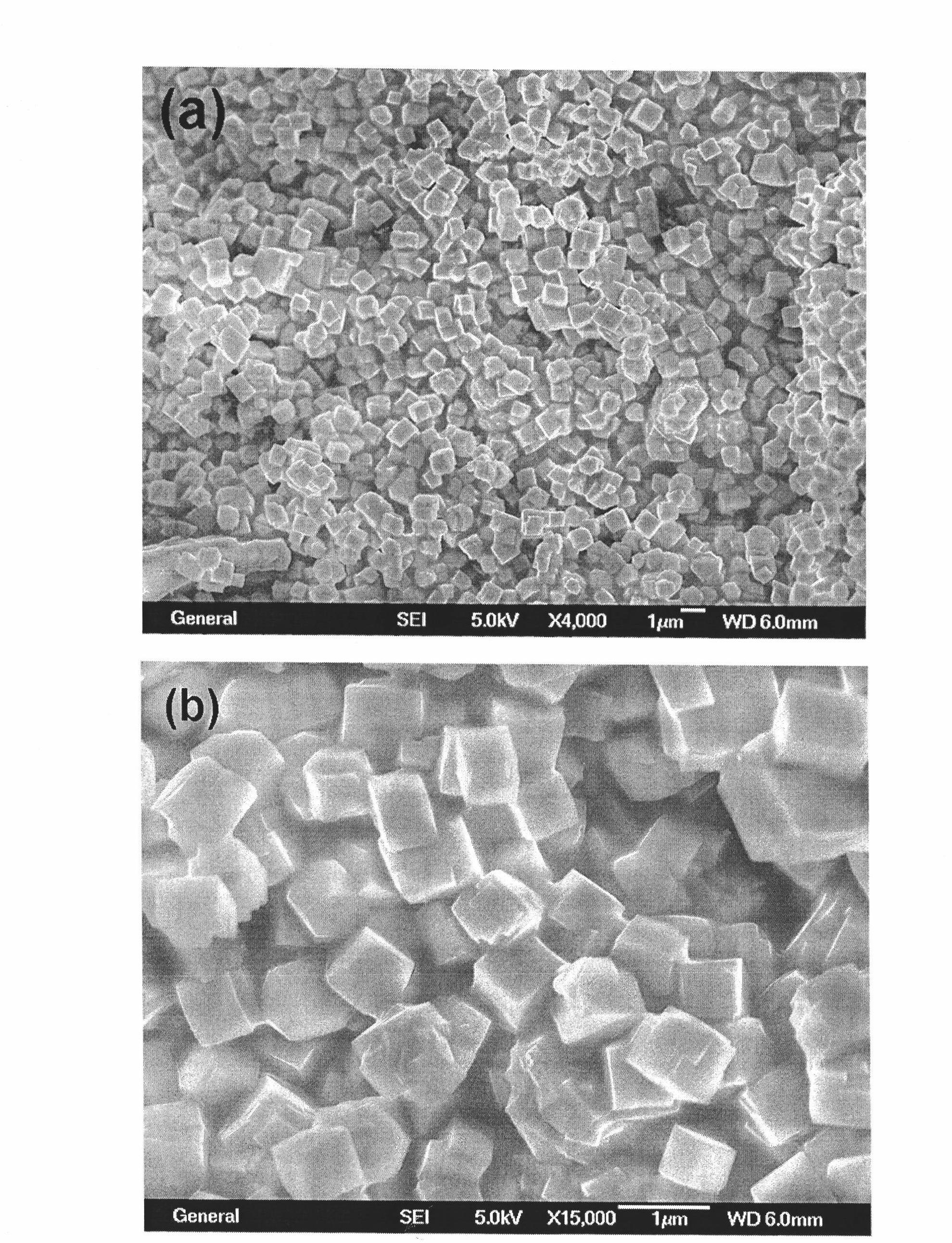

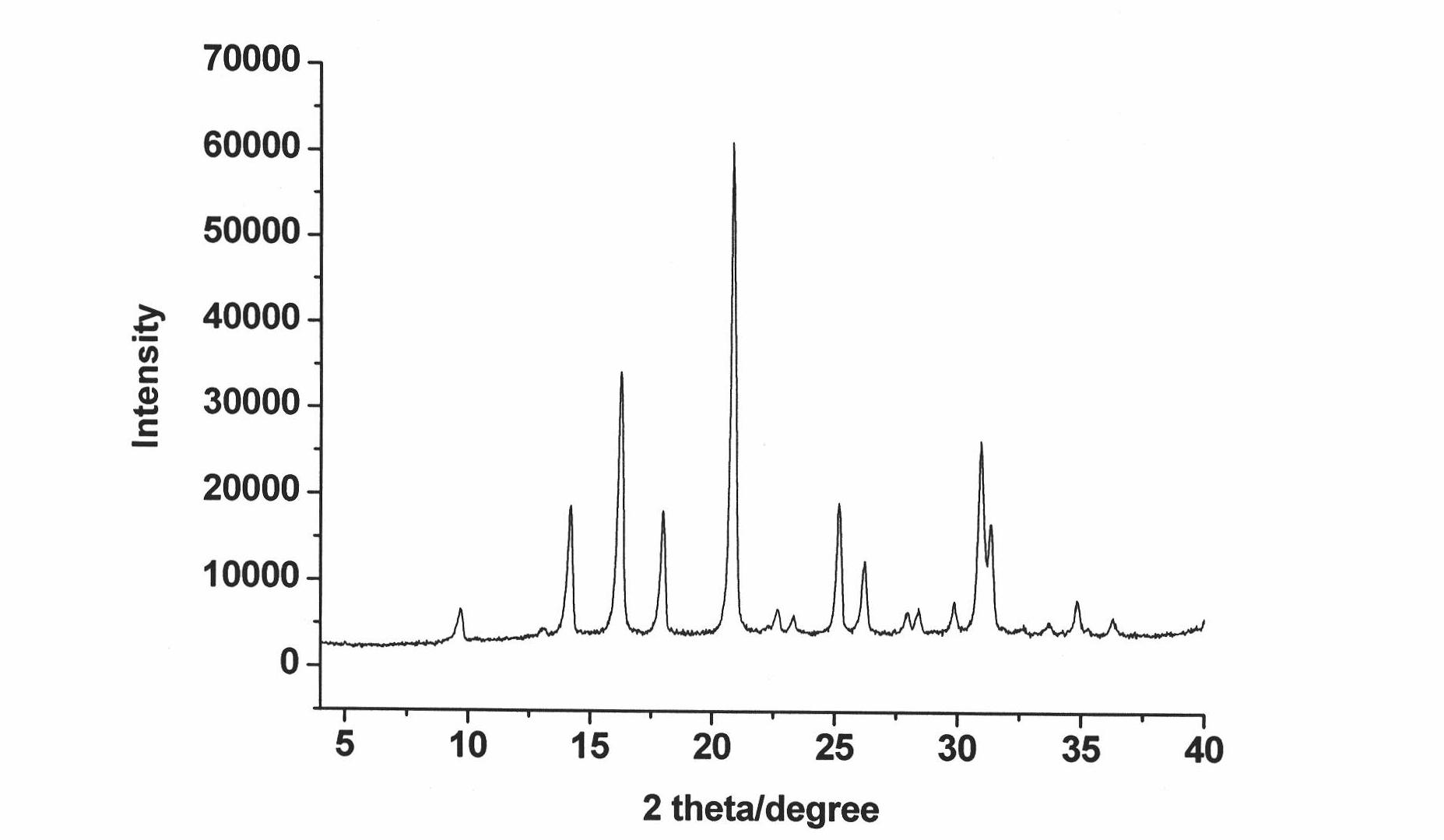

[0037] attached image 3 It is the XRD characterization result of the product, and it can be known that the product is a pure phase of CHA from the XRD characteristic peak.

[0038] attached Figure 4 It is a scanning electron microscope photo of the product. From the electron microscope characterization results, it can be seen that the product is a pure phase with high crystallinity. The sh...

Embodiment 3

[0039] Embodiment 3: the preparation of MOR sample

[0040] The addition sequence and stirring time of gel preparation are the same as in Example 1. The amount of each material is respectively 0.514 grams of sodium aluminate solid, 1.149 grams of copper sulfate pentahydrate solid, 3.342 grams of deionized water, 1.07 grams of tetraethylenepentamine, 0.366 grams of sodium hydroxide, and 4.99 milliliters of 31.5% silica sol. The chemical ratio is: 3.57Na 2 O: 1.0Al 2 o 3 : 15SiO 2 : 300H 2 O: 3.0Cu-R (wherein R: Cu = 1: 1), react at 180 degrees for two to six days. After the reaction is completed, the obtained product is fully washed with deionized water, and dried at 100 degrees for more than 12 hours.

[0041] attached Figure 5 It is a scanning electron micrograph of the product, which shows that the obtained product has a high degree of crystallinity, and large spherical crystals are piled up by small rod-shaped crystals.

[0042] attached Figure 6 It is the nitrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com