Method for preparing polyhedral oligomeric silsesquioxanes containing titanium phenyl

A technology of silsesquioxane and polysilsesquioxane, applied in the direction of titanium organic compounds, can solve problems such as co-precipitation side reactions and achieve the effect of strong reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

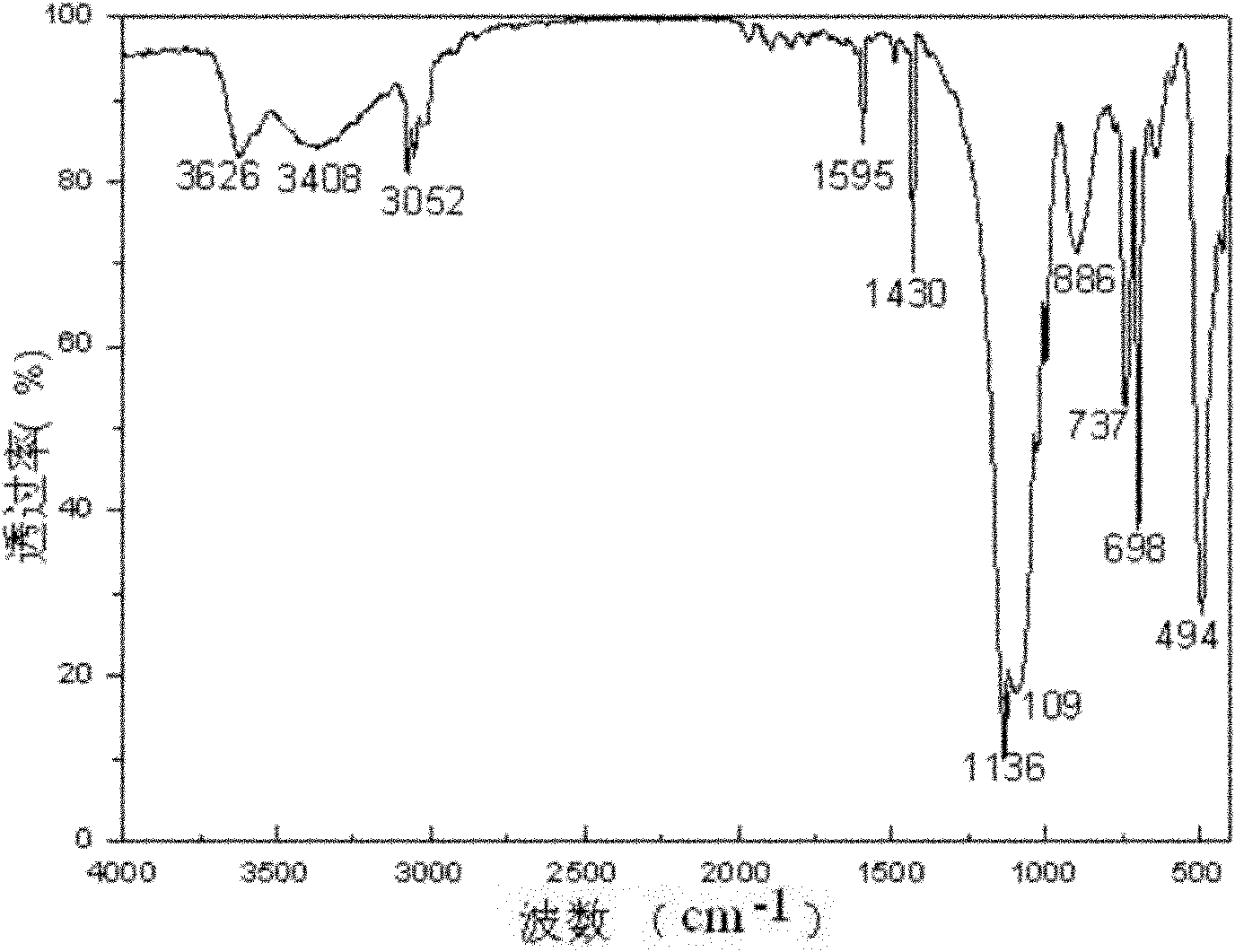

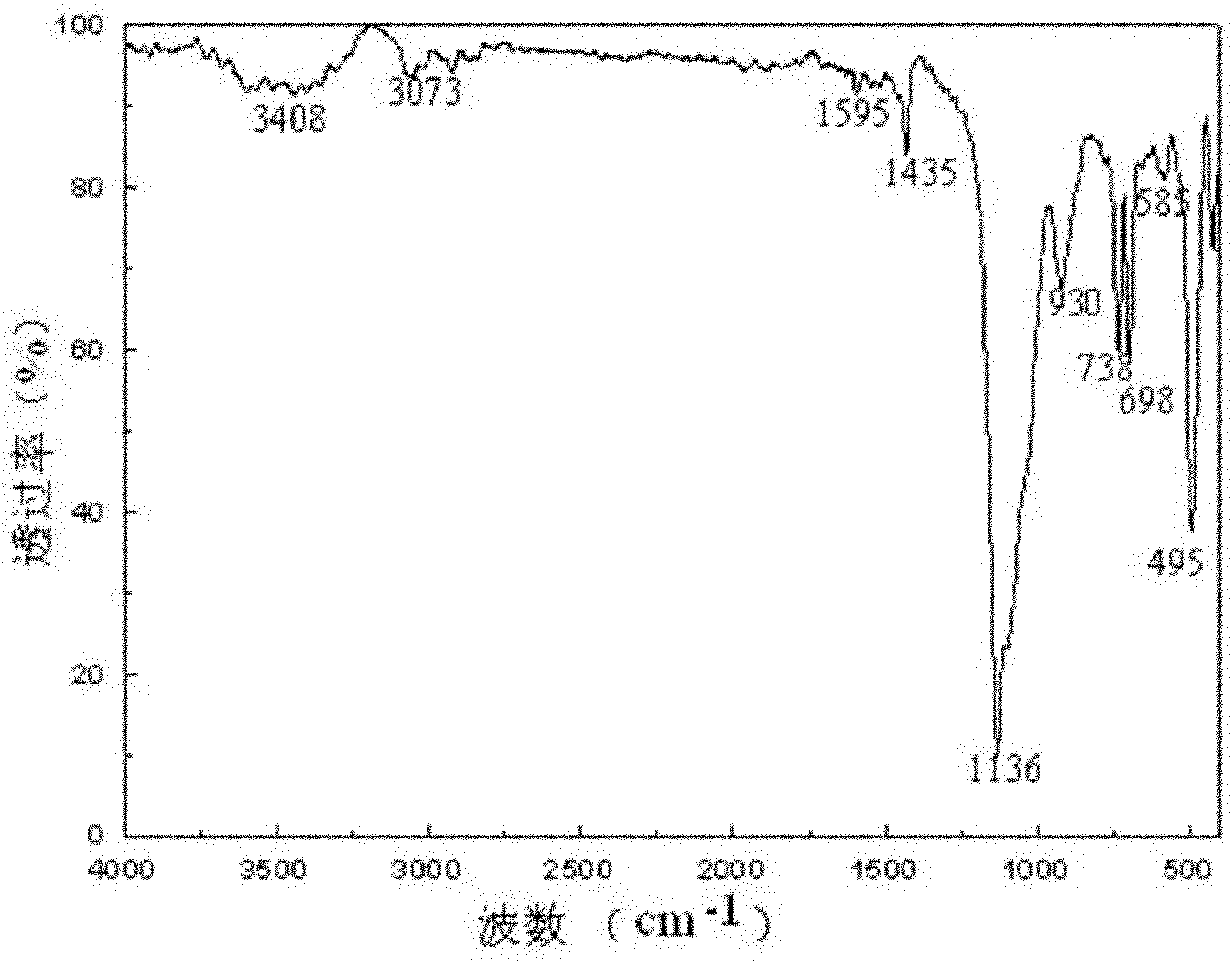

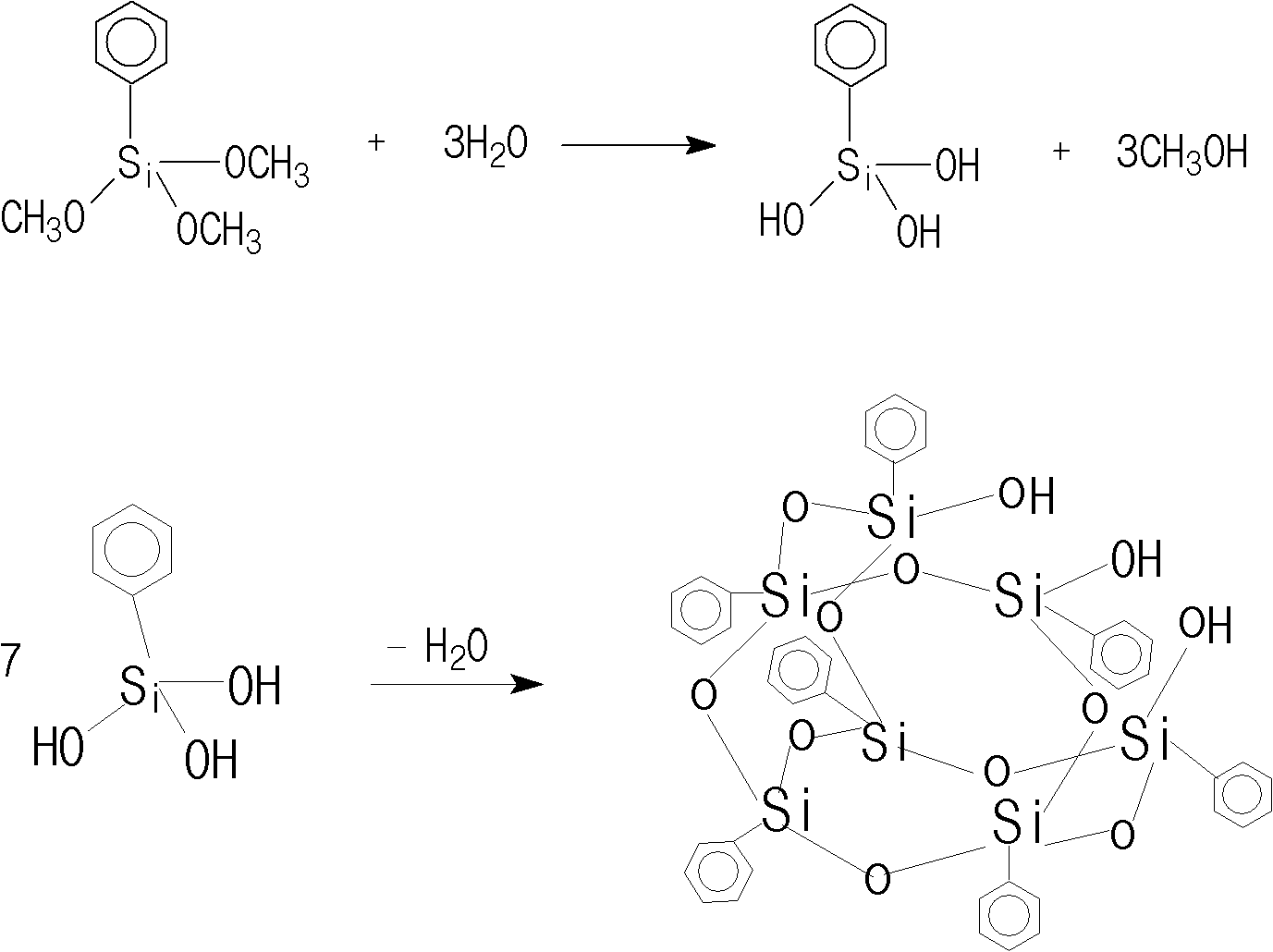

[0016] Specific embodiment one: the preparation method of the titanium-containing phenyl semi-cage silsesquioxane of the present embodiment is carried out according to the following steps: one, the volume ratio of phenyltrimethoxysiloxane and dehydrated alcohol is 1 : 4.5~5.5, the volume ratio of phenyltrimethoxysiloxane to acetic acid is 1:0.025~0.035, and the volume ratio of phenyltrimethoxysiloxane to water is 1:3~4. 1-phenyltrimethoxysiloxane, absolute ethanol, acetic acid and water; 2. Add the 1-phenyltrimethoxysiloxane, absolute alcohol and acetic acid weighed in step 1 to the container with reflux stirring device , stir evenly to obtain a mixed liquid, and then drop the water weighed in step 1 into the mixed liquid at a rate of 30 drops / minute to 35 drops / minute under the condition of stirring; ℃ and kept under reflux for 60h-65h, then the obtained mixture was left to age at room temperature for 40h-50h, the mixture was layered, and the upper layer was separated to obta...

specific Embodiment approach 2

[0018] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, the volume ratio of one-phenyltrimethoxysiloxane to absolute ethanol is 1:4.6~5.3, one-phenyltrimethoxysiloxane The volume ratio of oxane to acetic acid is 1:0.027~0.033, and the volume ratio of phenyltrimethoxysiloxane to water is 1:3.2~3.8. Weigh phenyltrimethoxysiloxane, anhydrous Ethanol, acetic acid and water. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019]Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step one, the volume ratio of one phenyltrimethoxysiloxane to absolute ethanol is 1:5.0, one phenyltrimethoxysiloxane The volume ratio of acetic acid is 1:0.030, and the volume ratio of monophenyltrimethoxysiloxane to water is 1:3.5. Weigh monophenyltrimethoxysiloxane, absolute ethanol, acetic acid and water. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com