Preparation method of glyphosate polymer

A technology of polymer and glyphosate, which is applied in the field of glyphosate polymer preparation, can solve the problems of slow-release effect of glyphosate polymer preparation, loss and decomposition of pesticides, small effective dose, etc., to achieve full play, The effect of long-lasting effect and reducing the frequency of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

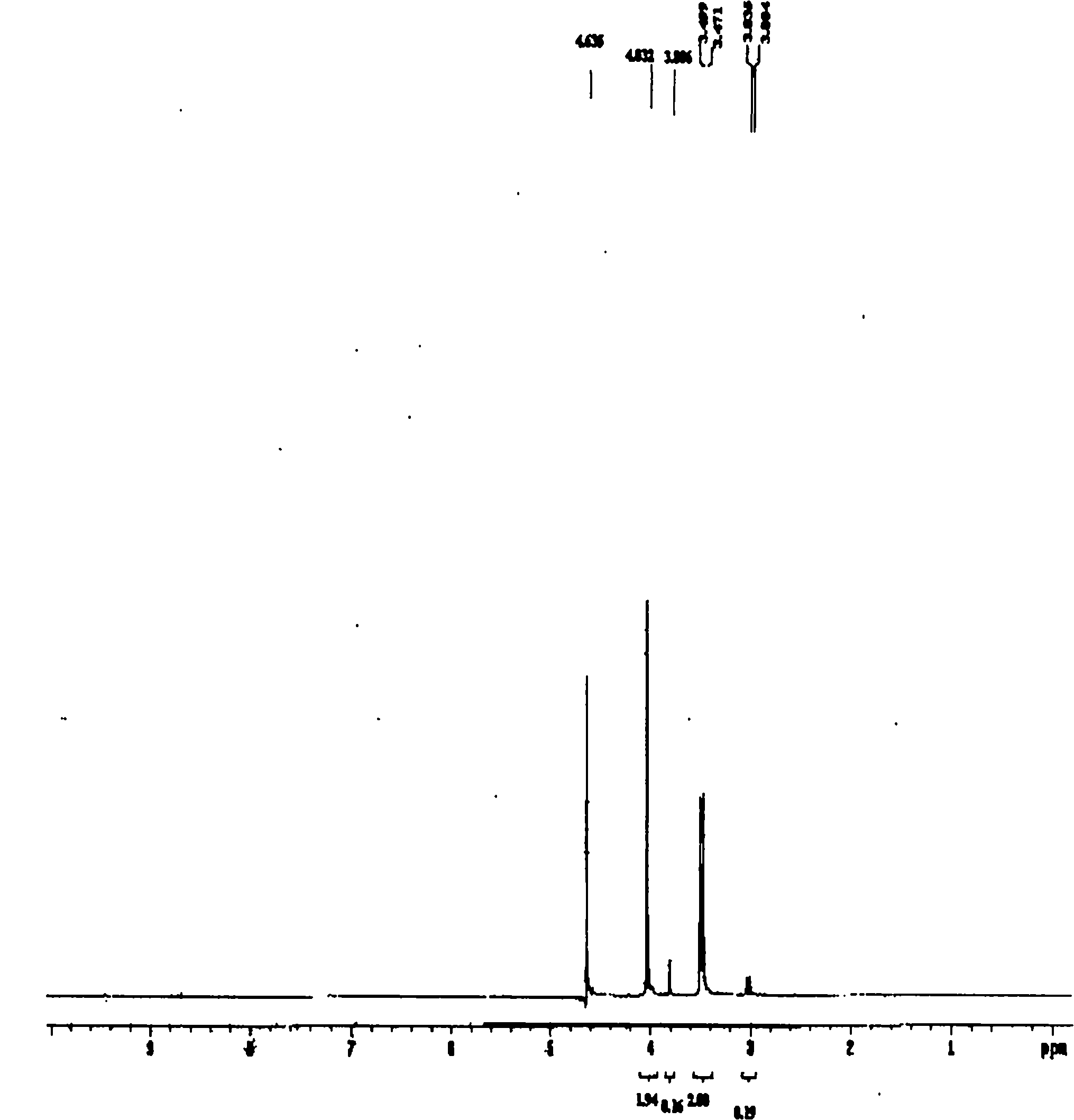

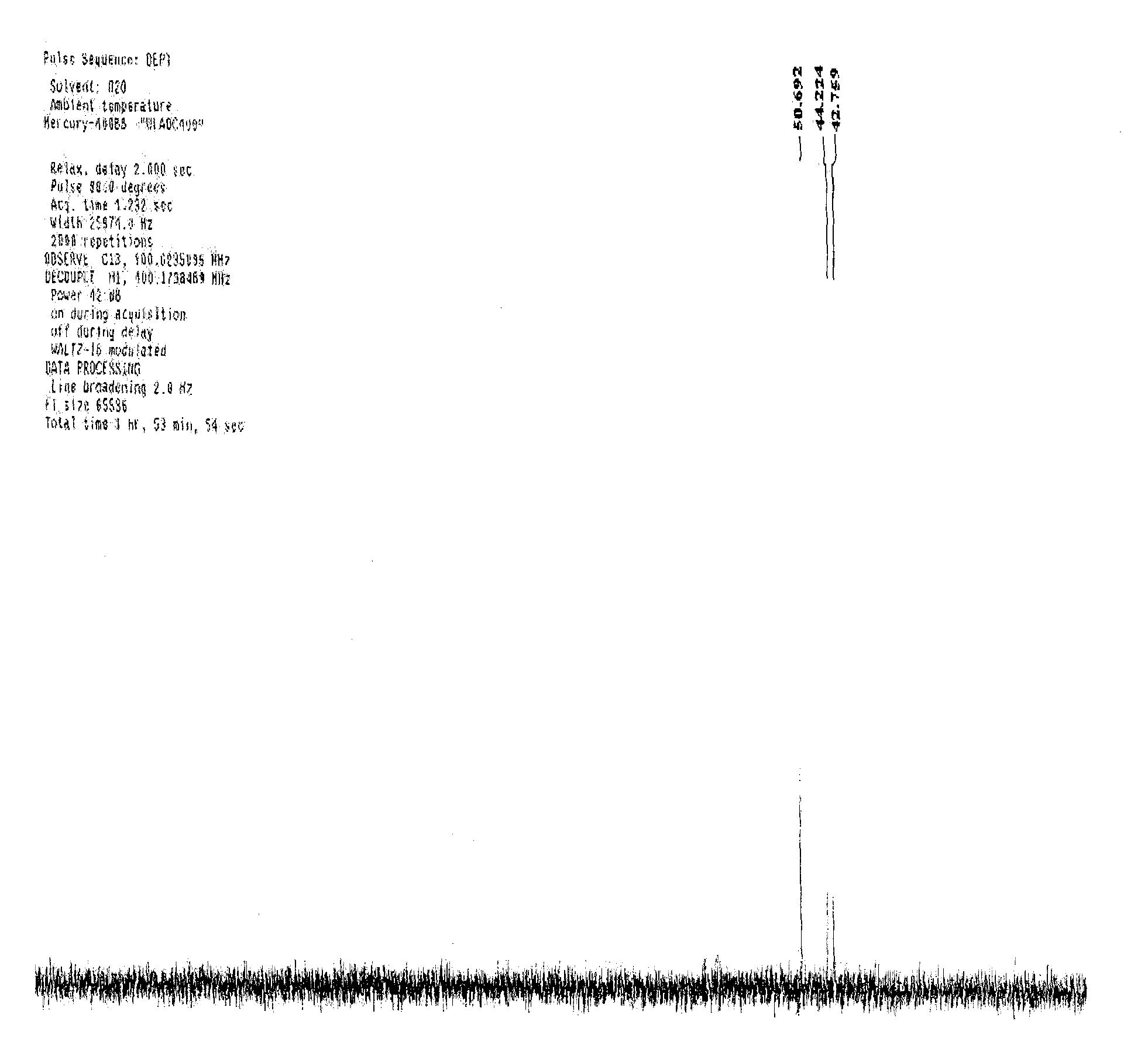

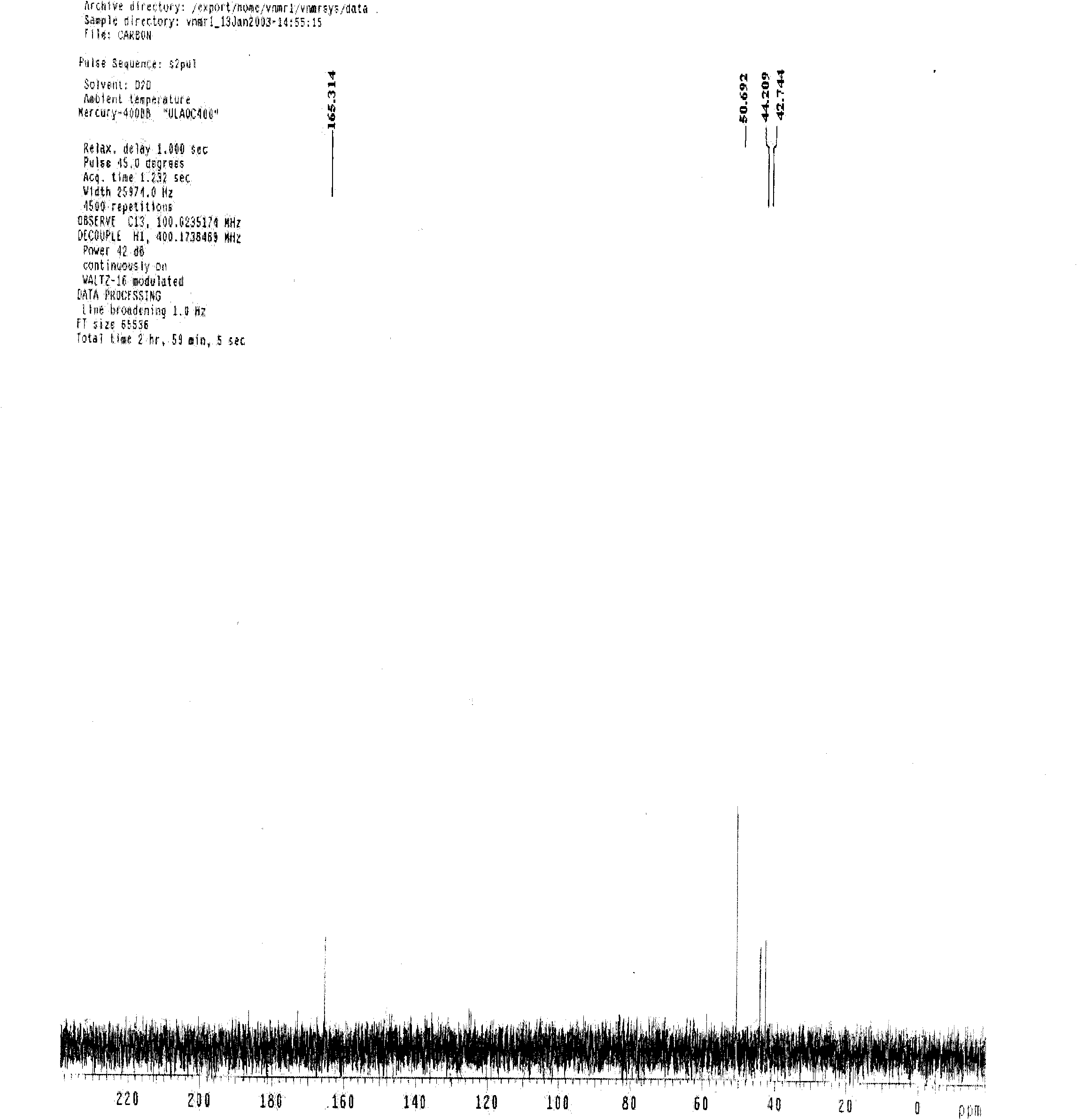

Image

Examples

preparation example Construction

[0016] Specifically, the preparation method of the glyphosate polymer in the embodiment of the present invention is that the glyphosate acid-catalyzed polycondensation method includes: mixing glyphosate acid with a catalyst and then adding water to prepare a mixed slurry, the catalyst being selected from phosphoric acid, sulfuric acid , phosphorous acid, polyphosphoric acid, potassium bisulfate, ammonium bisulfate; heating the above-mentioned mixed slurry for polycondensation reaction until the reaction is completed.

[0017] Furthermore, the weight ratio of glyphosate acid to the catalyst in the slurry is 1:0.01-1.5, and the weight ratio of the total amount of glyphosate acid and catalyst to water is 1:0.05-0.5.

[0018] Furthermore, the above-mentioned polycondensation reaction is carried out at a temperature of 70°C to 190°C. During heating, the catalyst is gradually evaporated.

[0019] Furthermore, the above polycondensation reaction time is 0.3-3 hours.

[0020] Furthe...

Embodiment 1

[0031] The obtained glyphosate polymer is prepared into 60% glyphosate lactone water-dispersible granules and common 60% glyphosate water-dispersible granules to carry out bioassay respectively, list 1-1, 1-2, 1-3 Compare the differences in the persistence and efficacy of the two medicines.

[0032] After harvesting the previous crop of rice, apply medicine 5-7 days before transplanting the latter crop of rice, drain the field water for 2-3 days before using the medicine, spray with 10 kg of water per mu, and then transplant the rice after water retention for 3-5 days. The blank control did not apply pesticides and did not weed. After spraying, the transplanted rice was subjected to conventional cultivation treatment. The growth status of the weeds was visually observed 2 and 5 days after the application of the medicine, and the types and quantities of the weeds in each treatment were observed 15 days, 30 days and 50 days after the rice was transplanted. The calculation and ...

Embodiment 2

[0047] The prepared compound is made into 60% glyphosate lactone soluble powder and common 60% glyphosate soluble powder for bioassay respectively, and lists 2-1, 2-2, 2-3 compare the persistence of the two agents and differences in efficacy.

[0048] After harvesting the previous crop of rice, apply medicine 5-7 days before transplanting the latter crop of rice, drain the field water for 2-3 days before using the medicine, spray with 10 kg of water per mu, and then transplant the rice after water retention for 3-5 days. The blank control did not apply pesticides and did not weed. After spraying, the transplanted rice was subjected to conventional cultivation treatment. The growth status of the weeds was visually observed 2 and 5 days after the application of the medicine, and the types and quantities of the weeds in each treatment were observed 15 days, 30 days and 50 days after the rice was transplanted. The calculation and analysis method of drug efficacy is as follows; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com