Magnetic suspension bearing of hybrid magnetic circuit

A magnetic levitation bearing and hybrid magnetic circuit technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of large electric power, high weight, large volume, etc., achieve low loss and temperature rise, small volume, and good control characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

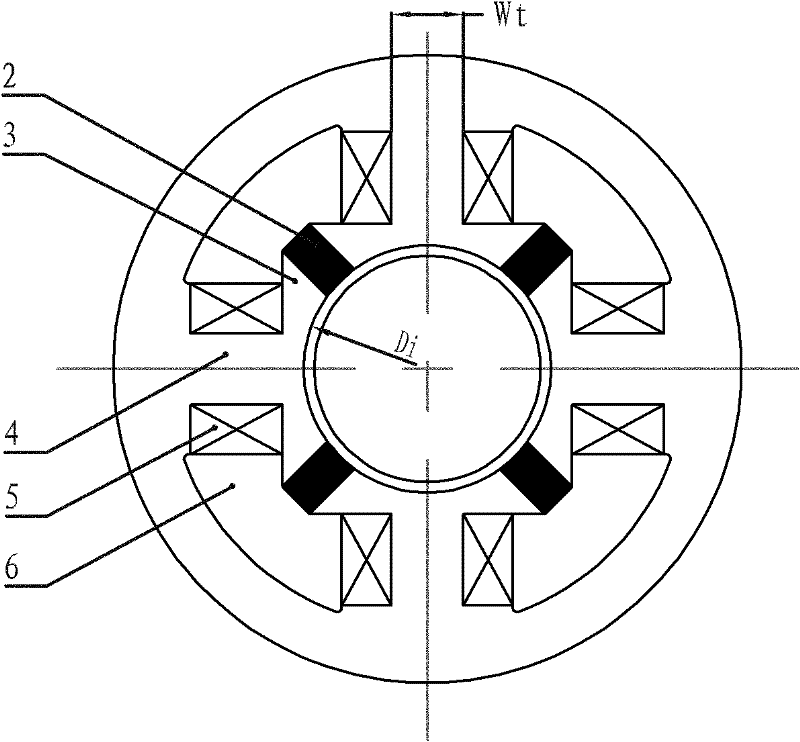

[0010] Embodiment 1: The hybrid magnetic circuit magnetic suspension bearing of this embodiment is composed of a stator, a rotor and an air gap. The stator is composed of a stator core, an excitation coil 5 and an excitation permanent magnet 2. The end face of the stator core is circular, and on the side of the stator In the wall, there are four through holes 6 with fan-shaped end faces along the moving direction of the rotor. The four through holes 6 have the same shape and are distributed symmetrically with the central axis of the stator. Between two adjacent through holes 6 are Stator teeth 4, the width W of the stator teeth 4 along the circumferential direction t Meet the conditions: W t i / 4, where D i is the inner diameter of the stator core, each stator tooth 4 is wound with an excitation coil 5, the part between the outer wall of the stator and the tooth root of the stator tooth 4 is an annular yoke, and the part between the four through holes 6 of the stator and the ...

specific Embodiment approach 2

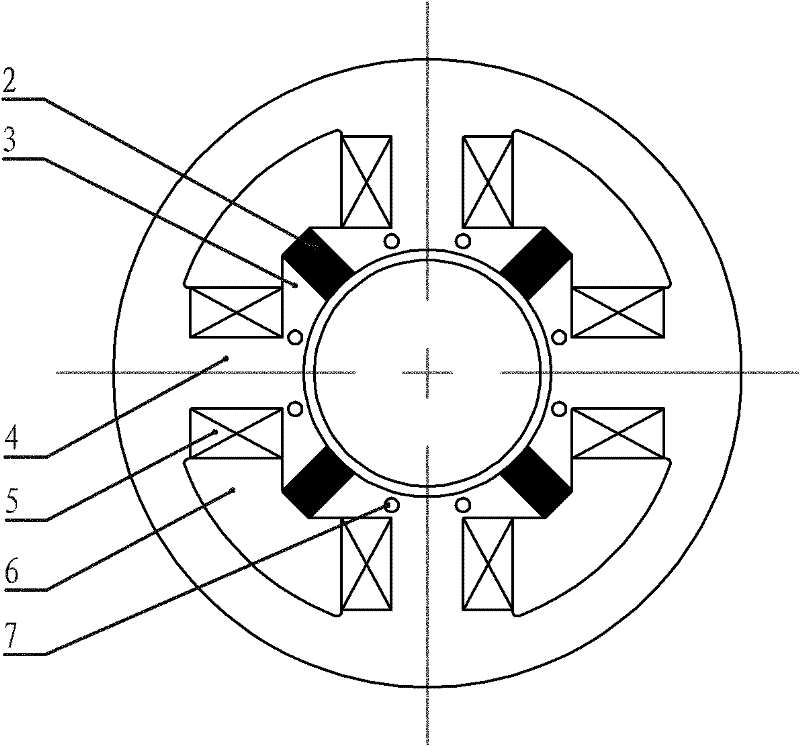

[0012] Specific implementation mode two: see figure 2 This embodiment will be described. The difference between the present embodiment and the first embodiment is that an axial magnetic isolation hole 7 is provided at the connection between each stator tooth 4 and the adjacent permanent magnet collecting yoke 3 .

[0013] In this embodiment, a magnetic isolation hole 7 is added at the connection between the permanent magnet yoke 3 and the stator tooth 4, which can effectively reduce the mutual influence between the magnetic flux of the permanent magnet 2 and the electric excitation flux, and improve the control accuracy of the bearing.

specific Embodiment approach 3

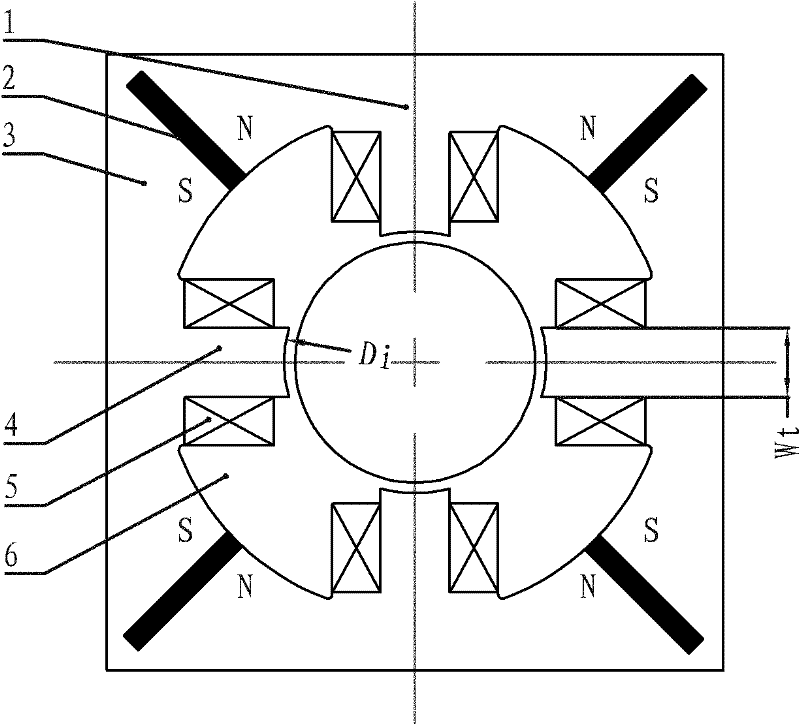

[0014] Specific Embodiment Three: The hybrid magnetic circuit magnetic suspension bearing of this embodiment is mainly composed of a stator, a rotor and an air gap. The stator includes a stator core, an excitation coil 5 and an excitation permanent magnet 2. The inner wall of the stator core is evenly distributed along the circumferential direction with four stator teeth. 4. The width W of each stator tooth 4 along the circumferential direction t Meet the conditions: W t i / 4, where D i is the inner diameter of the stator core, and each stator tooth 4 is wound with an excitation coil 5; between every two adjacent stator teeth 4 is the groove of the stator core, and the part of the stator core located at the root of the stator teeth 4 is the magnetic yoke 1, The stator core part between two adjacent stator teeth 4 is a permanent magnet poly yoke 3, and the permanent magnet poly yoke 3 is a mirror symmetrical structure. On the inner wall of each permanent magnet poly yoke 3, al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com