Method for improving performances of dye sensitized solar cell

A solar cell and dye sensitization technology, which is applied in the field of improving the performance of dye-sensitized solar cells, can solve the problems of increasing the open circuit voltage, and the dye-sensitized solar cell has not yet been seen, and achieves the effect of improving the open circuit voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The specific steps of a method for improving the performance of dye-sensitized solar cells are:

[0019] 1) Preparation method of electrode material: 0.8 g of TiO 2 The powder is placed in a polytetrafluoroethylene conical container containing 150 milliliters of 10 mol / liter NaOH solution, and the container is placed in an oil bath at 80° C. for 5 days with magnetic stirring to obtain a white flocculent precipitate. Wash with 1 liter of HCl until neutral, and dry at 60°C for 5 hours to obtain titanium dioxide nanotubes;

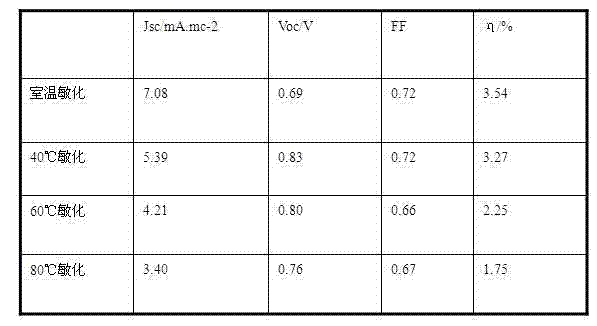

[0020] 2) Assembly of dye-sensitized solar cells: prepare a slurry of titanium dioxide nanotubes and a binder, print it on a conductive glass by screen printing, bake it at 510°C for 3 hours, and use TiCl 4 treatment, roasting at 400°C for 40min, with a thickness of 20 microns, and then dipping it in organic dye D131 to seal it, placing it in a water bath at 40°C for 7 hours, and taking it out, the color of the electrode film changed from white to br...

Embodiment 2

[0023] The specific steps of a method for improving the performance of dye-sensitized solar cells are:

[0024] 1) The preparation method of the electrode material: 1.5 g of TiO 2 The powder is placed in a polytetrafluoroethylene conical container containing 210 milliliters of 10 mol / liter NaOH solution, and the container is placed in an oil bath at 120°C for 3 days with magnetic stirring to obtain a white flocculent precipitate. Wash with 1 liter of HCl until neutral, and dry at 80°C for 3 hours to obtain titanium dioxide nanotubes;

[0025] 2) Assembly of dye-sensitized solar cells: Prepare a slurry of titanium dioxide nanotubes and a binder, print it on a conductive glass by screen printing, bake it at 530°C for 1.5 hours, and use TiCl 4 treatment, roasting at 500°C for 20min, with a thickness of 25 microns, and then dipping it in organic dye D131 to seal it, placing it in a water bath at 60°C for 5 hours and taking it out, the color of the electrode film changed from whi...

Embodiment 3

[0028] The specific steps of a method for improving the performance of dye-sensitized solar cells are:

[0029] 1) Preparation method of electrode material: 1.0 g of TiO 2 The powder is placed in a polytetrafluoroethylene conical container containing 180 milliliters of 10 mol / liter NaOH solution, and the container is placed in an oil bath at 100°C for 4 days with magnetic stirring to obtain a white flocculent precipitate. Wash with 1 liter of HCl until neutral, and dry at 70°C for 4 hours to obtain titanium dioxide nanotubes;

[0030] 2) Assembly of dye-sensitized solar cells: prepare a slurry of titanium dioxide nanotubes and a binder, use screen printing, print it on a conductive glass, bake it at 520°C for 2 hours, and use TiCl 4 treatment, roasting at 450°C for 30min, with a thickness of 22 microns, and then dipping it in organic dye D131 to seal it, placing it in a water bath at 50°C for 6 hours, and taking it out, the color of the electrode film changed from white to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com