A poly-3,4-ethylenedioxythiophene-coated tungsten oxide nanorod, its preparation method and its application

A technology of ethylenedioxythiophene and tungsten oxide nanowires, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of unfavorable photogenerated hole collection and transmission, and improve energy conversion Efficiency, simple process steps, and the effect of improving efficiency and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

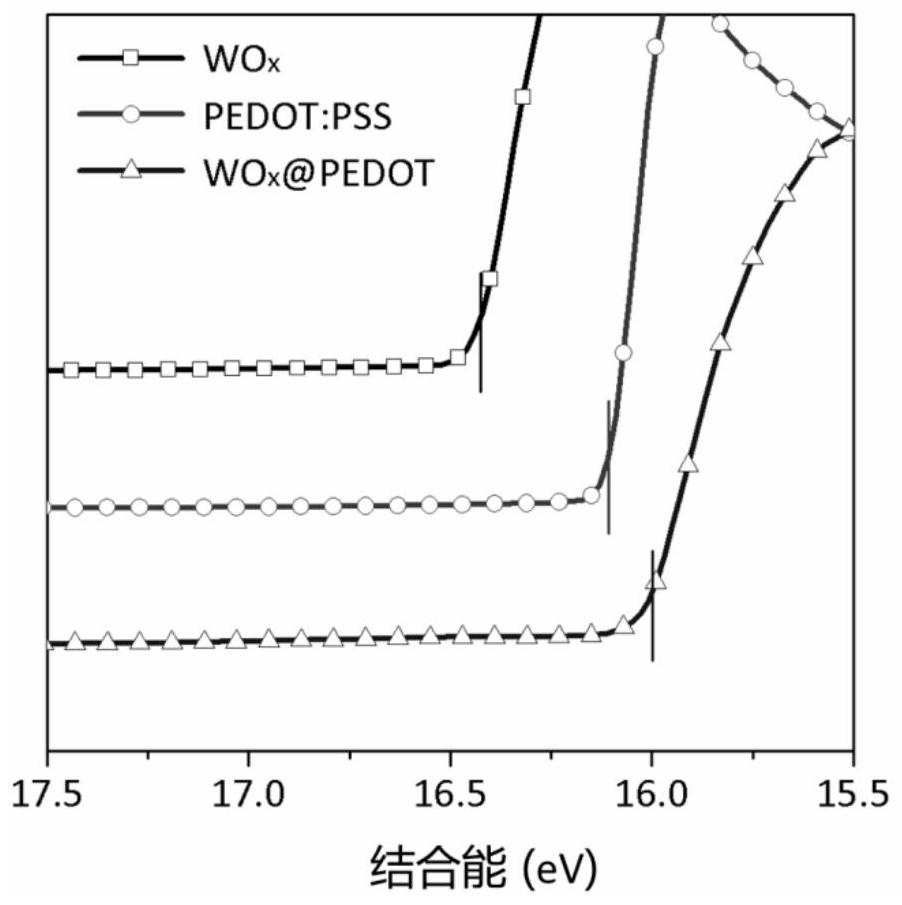

[0027] This embodiment provides a poly-3,4-ethylenedioxythiophene-coated tungsten oxide nanorod (abbreviated as WO X @PEDOT nanorod) and preparation method thereof, specifically:

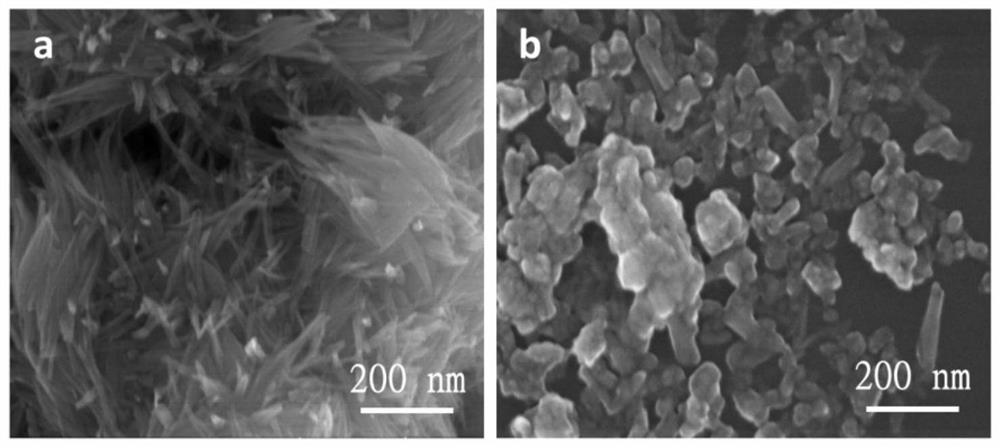

[0028] (a) Preparation of WO X Nanowires (reference: Journal of Materials Chemistry A, 2013, 1, 6125-6129): WCl 6 Dissolve in ethanol to prepare a solution with a concentration of 12.5mg / mL (stir for 15 minutes until completely dissolved); transfer the solution to a hydrothermal reaction kettle, and react at 180°C for 24 hours to generate WO X After the nanowires were cooled to normal temperature, they were washed with deionized water and ethanol for 3 times, and then dried in a vacuum oven at 45°C for one night. figure 1 (a));

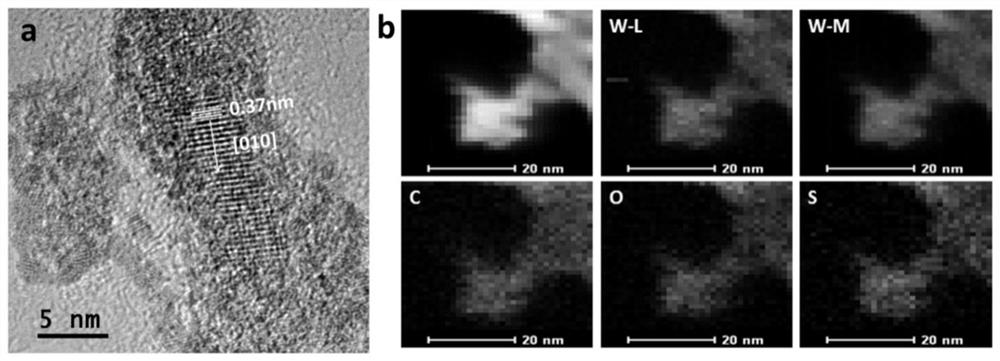

[0029] (b) Preparation of WO X @PEDOT Nanorods: Take 35mg of WO X Disperse the nanowires in 1mL deionized water, add 8μLEDOT dropwise, and stir thoroughly at room temperature for 30 days (rotating speed 500-800rpm) until the solution turns dark blue; then let it stand ...

Embodiment 2

[0031]This embodiment provides a poly-3,4-ethylenedioxythiophene-coated tungsten oxide nanorod (abbreviated as WO X @PEDOT nanorods) and its preparation method are basically the same as in Example 1, except that in step (b), 16 μL of EDOT is added dropwise.

Embodiment 3

[0033] This embodiment provides a poly-3,4-ethylenedioxythiophene-coated tungsten oxide nanorod (abbreviated as WO X @PEDOT nanorods) and its preparation method are basically the same as those in Example 1, except that in step (b), 24 μL of EDOT is added dropwise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com