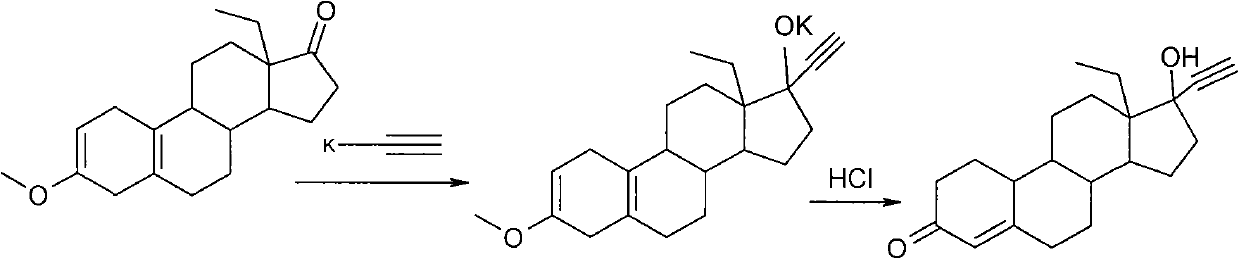

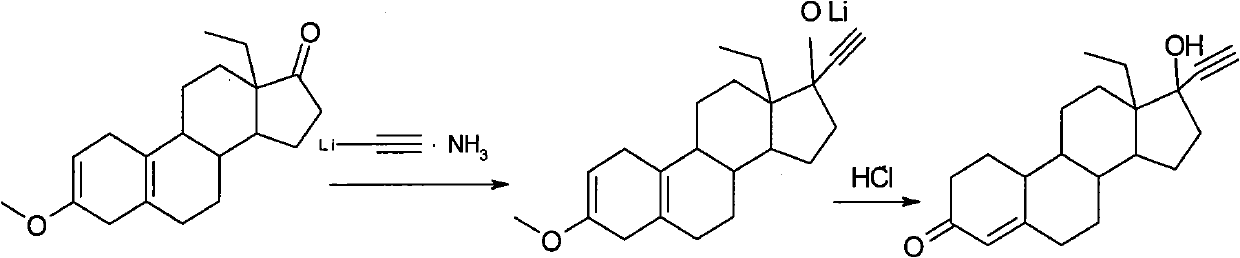

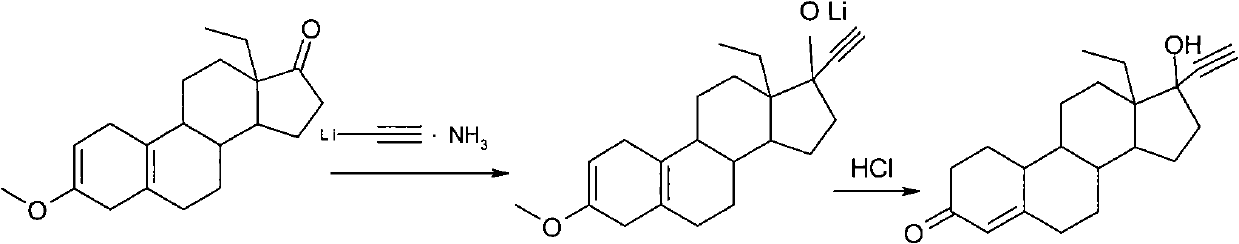

Synthesis process of levonorgestrel by methoxydienone

A technology of levonorgestrel and Worth's substance, which is applied in the technical field of synthesizing levonorgestrel from Worth's substance, can solve the problems of difficult reaction and the like, and achieves fast reaction speed, easy control of production conditions and process conditions. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation of the first step alkynyl lithium ammonia complex:

[0029] a. Inject 500ml of liquid ammonia into a 1000ml three-necked reaction bottle, and control the temperature in the bottle at -55 to -50°C, add 10.5g of lithium metal under stirring, and add the time for 20 minutes;

[0030] b. After the lithium metal is completely dissolved in the liquid ammonia, control the temperature inside the bottle at -50°C, and feed acetylene gas into the bottle at a flow rate of 4L / min until the liquid ammonia solution changes from blue-black to gray-white, and then feed acetylene Gas 5min;

[0031] c. Use normal temperature water to heat up the outside of the reaction bottle, continue to volatilize liquid ammonia, and add 600ml methyl tert-butyl ether at the same time to make it react;

[0032] d. When the volume of the reaction liquid in the reaction bottle reaches 500ml after adding methyl tert-butyl ether, add a coolant to the reaction bottle to reduce the temperature...

Embodiment 2

[0041] The preparation of the first step alkynyl lithium ammonia complex:

[0042] a. Inject 500ml of liquid ammonia into a 1000ml three-necked reaction bottle, and control the temperature in the bottle at -55 to -50°C, add 11g of lithium metal under stirring, and add the time for 20 minutes;

[0043] b. After the lithium metal is completely dissolved in the liquid ammonia, control the temperature inside the bottle at -50°C, and feed acetylene gas into the bottle at a flow rate of 4L / min until the liquid ammonia solution changes from blue-black to gray-white, and then feed acetylene Gas 5min;

[0044] c. Heat up with normal temperature water on the outside of the reaction bottle, continue to volatilize liquid ammonia, and add 500ml toluene at the same time to make it react;

[0045] d. When the temperature of the reaction liquid in the reaction bottle reaches 10°C after adding toluene, add a coolant to the reaction bottle to reduce the temperature of the reaction liquid in th...

Embodiment 3

[0054] The preparation of the first step alkynyl lithium ammonia complex:

[0055] a. Inject 500ml of liquid ammonia into a 1000ml three-necked reaction bottle, and control the temperature in the bottle at -55 to -50°C, add 10.5g of lithium metal under stirring, and add the time for 20 minutes;

[0056] b. After the lithium metal is completely dissolved in the liquid ammonia, control the temperature inside the bottle at -50°C, and feed acetylene gas into the bottle at a flow rate of 4L / min until the liquid ammonia solution changes from blue-black to gray-white, and then feed acetylene Gas 5min;

[0057] c. Use normal temperature water to heat up the outside of the reaction bottle, continue to volatilize liquid ammonia, and add 600ml tetrahydrofuran to make it react;

[0058] d. When the volume of the reaction liquid in the reaction bottle reaches 500ml after adding tetrahydrofuran, add a coolant to the reaction bottle to reduce the temperature of the reaction liquid in the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com