Method for preparing CuAl2O3 composite material through spray co-deposition reaction

A composite material and cual2o3 technology, which is applied in the field of preparing CuAl2O3 composite materials by spray co-deposition reaction, can solve the problems of long production cycle, unfavorable industrial production, segregation of reinforced aluminum oxide, etc., and achieves thermal stability and thermal strength. performance improvement, the preparation process is easy to control, and the effect of solving the difficulty of subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

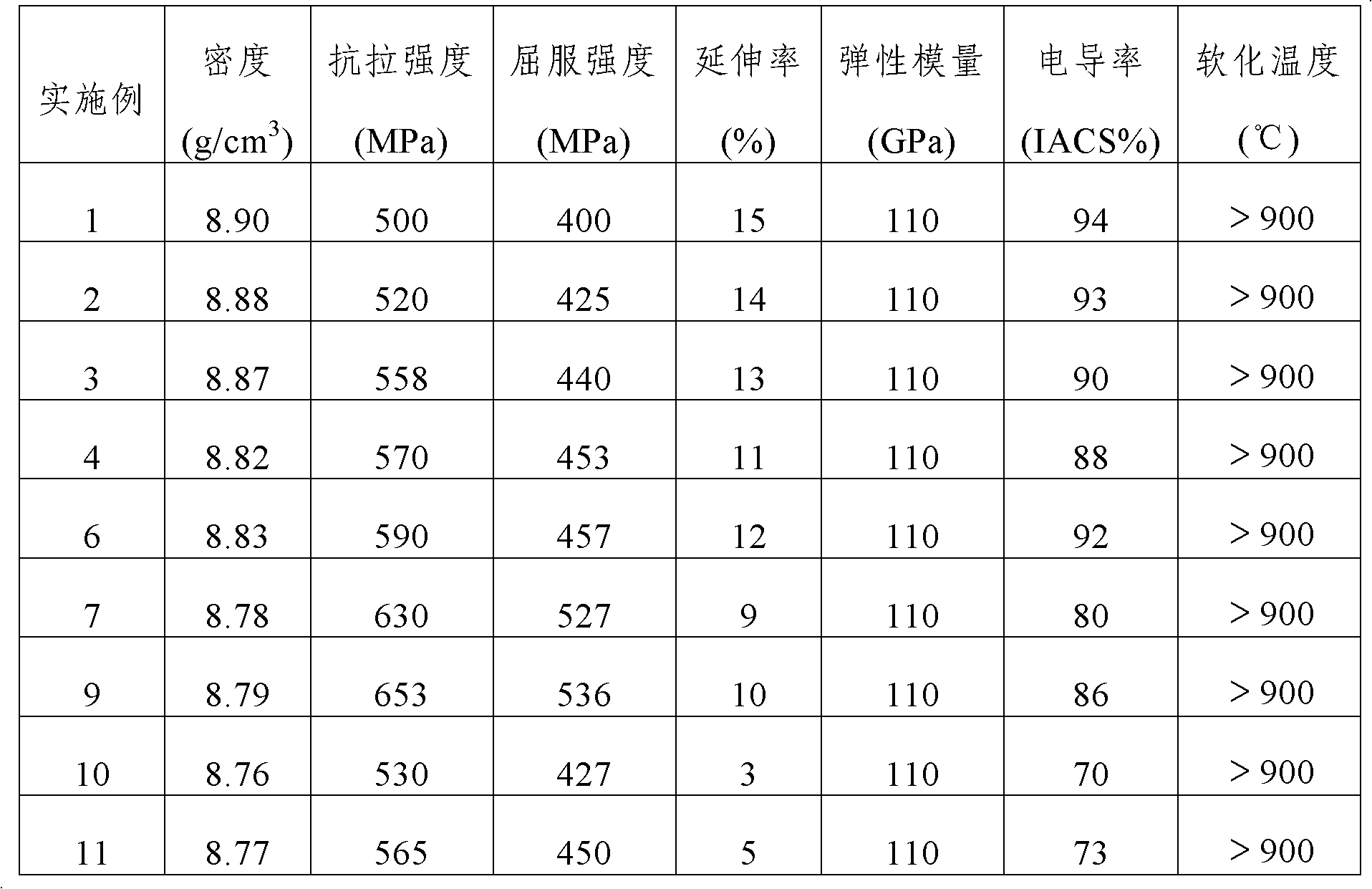

Examples

Embodiment 1

[0024] (1) Treat CuO powder with a particle size of 10 μm at a temperature of 100° C. for 2 hours;

[0025] (2) Place a mixture of Cu with a mass purity ≥ 99.9% and Al with a mass purity ≥ 99.9% in a spray co-deposition vacuum intermediate frequency melting furnace, and alloy it at a temperature of 1040°C to obtain an alloy melt; in the mixture The mass percentage of Al is 0.1%, and the balance is Cu;

[0026] (3) After the temperature of the alloy melt reaches 200°C, open the atomizing gas valve, pour the alloy melt into the insulation bag at the same time, and start the powder conveying device to transport the processed CuO powder, and perform spray co-deposition to obtain CuAl / CuO alloy; the amount of the CuO powder is 3 / 2 times the molar amount of Al; the deposition distance of the spray co-deposition is 300mm, the atomizing gas pressure is 2.0MPa, the inner diameter of the draft tube is 3.5mm, and the speed of the depositor is 10rpm / min;

[0027] (4) Under vacuum condi...

Embodiment 2

[0030] The preparation method of this example is the same as that of Example 1, except that: the particle size of CuO powder is 100 μm, the temperature of CuO powder treatment is 200° C., and the treatment time is 0.5 h; the mass percentage of Al in the mixture is 2%; The alloying temperature is 1070°C. After the alloy melt temperature reaches 100°C, the atomizing gas valve is opened; the deposition distance of spray co-deposition is 400mm, the atomizing gas pressure is 0.8MPa, the inner diameter of the guide tube is 4mm, and the speed of the depositor is The temperature of the in-situ chemical reaction is 800°C, and the time of the in-situ chemical reaction is 10h; the temperature of the extrusion is 600°C.

Embodiment 3

[0032] The preparation method of this example is the same as that of Example 1, except that the particle size of CuO powder is 55 μm, the temperature of CuO powder treatment is 300° C., and the treatment time is 1.3 h; the mass percentage of Al in the mixture is 4%; The alloying temperature is 1100°C. After the alloy melt temperature reaches 150°C, the atomizing gas valve is opened; the deposition distance of jet co-deposition is 350mm, the atomizing gas pressure is 1.4MPa, and the inner diameter of the guide tube is 4.5mm. The rotation speed is 40rpm / min; the temperature of the in-situ chemical reaction is 900°C, and the time of the in-situ chemical reaction is 7h; the extrusion temperature is 500°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com