Design method of artificial elbow joint prosthesis with tantalum coating

A design method and elbow joint technology, applied in the field of biomedical composite materials, to achieve the effect of increasing bone ingrowth, high bonding strength, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

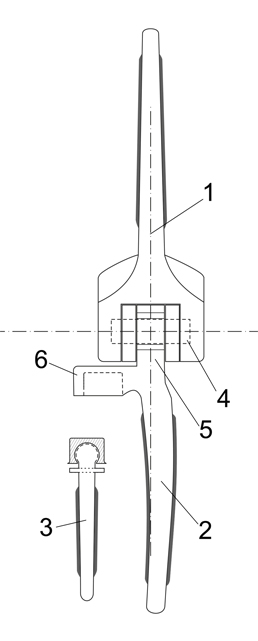

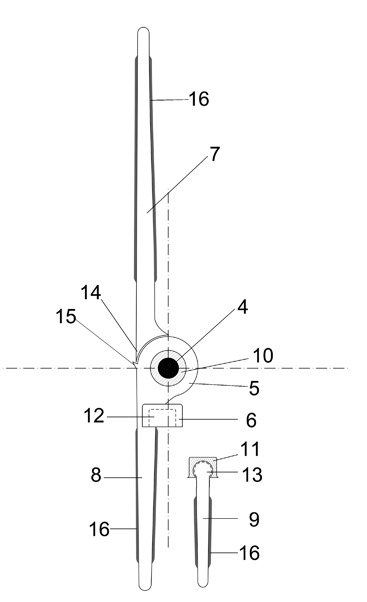

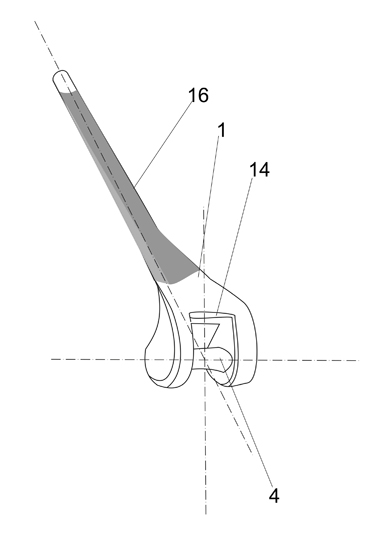

[0020] Such as figure 1 , 2 , 3, the present invention includes humeral component 1, ulna component 2 and radial component 3 three parts; 3 three components all contain handle body and joint connection structure, and the shape of each component handle body and the bone marrow cavity space of corresponding human body The shape fits well to facilitate the insertion of the stem into the corresponding bone marrow cavity; the shape of the stem is tapered from thick to thin to prevent the stem from sinking and shifting in the bone medullary cavity; the humeral component is changed from thin to thick Cylindrical or conical shank 7 and a thicker end that is arc-shaped and over-expanded joint connection structure, the center of the joint connection structure is the crankshaft 4, and the radial joint sleeve 5 and the surrounding polyethylene The pads 10, 17 together form an articulating structure. The ulna component 1 and the humerus component 2 can perform limited flexion and extensi...

Embodiment 2

[0028] Using materials such as medical stainless steel 00Cr18Ni14Mo3 or 00Cr18Ni15Mo3N, titanium Ti, titanium alloy Ti-6Al-4V or cobalt-chromium-molybdenum alloy Co30Cr6Mo0.35C as the base part of the prosthesis, taking advantage of its high mechanical strength, the artificial prosthesis provides more Strong mechanical strength, so that the prosthesis can bear the physiological load and motion load of the human body without material fatigue or damage; the application of hard Al 2 o 3Or SiC sand is used as the medium to carry out sandblasting pretreatment on the outer surface of the stem 1 of the artificial prosthesis base and the outer surface of the elbow cup 3 to form a rough surface on the surface of the prosthesis base to facilitate the bonding strength of the coating; adopt biocompatible Metal tantalum material with good performance, corrosion resistance, wear resistance and high bonding strength is used as the coating material. The contact part between the base of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com