Novel pharmaceutical composition containing analgesic

A technology of composition and analgesic, which is applied in the field of preparation of sustained-release dosage forms, and can solve problems such as poor analgesic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0026] Unit: mg

[0027] raw material

[0028] tramadol hydrochloride

[0029] The manufacturing method adopts general wet granulation. After sieving the drugs other than magnesium stearate and hydroxypropyl methylcellulose through a No. 35 sieve (500 μm), put them into a high-speed rotary machine and mix for 2 to 4 minutes. Then put in an appropriate amount of adhesive liquid, and after about 2-3 minutes of bonding, put it into the boiling drying machine, and dry it at a temperature of 60-70 degrees until the drying reduction is 0.5-3.0%. The dried granules are shaken and sieved with a No. 18 sieve to granulate, put into a V-shaped mixer together with magnesium stearate and mix for 3 minutes, and be compressed into tablets with a size of 4 to 8 kgf with a tablet machine.

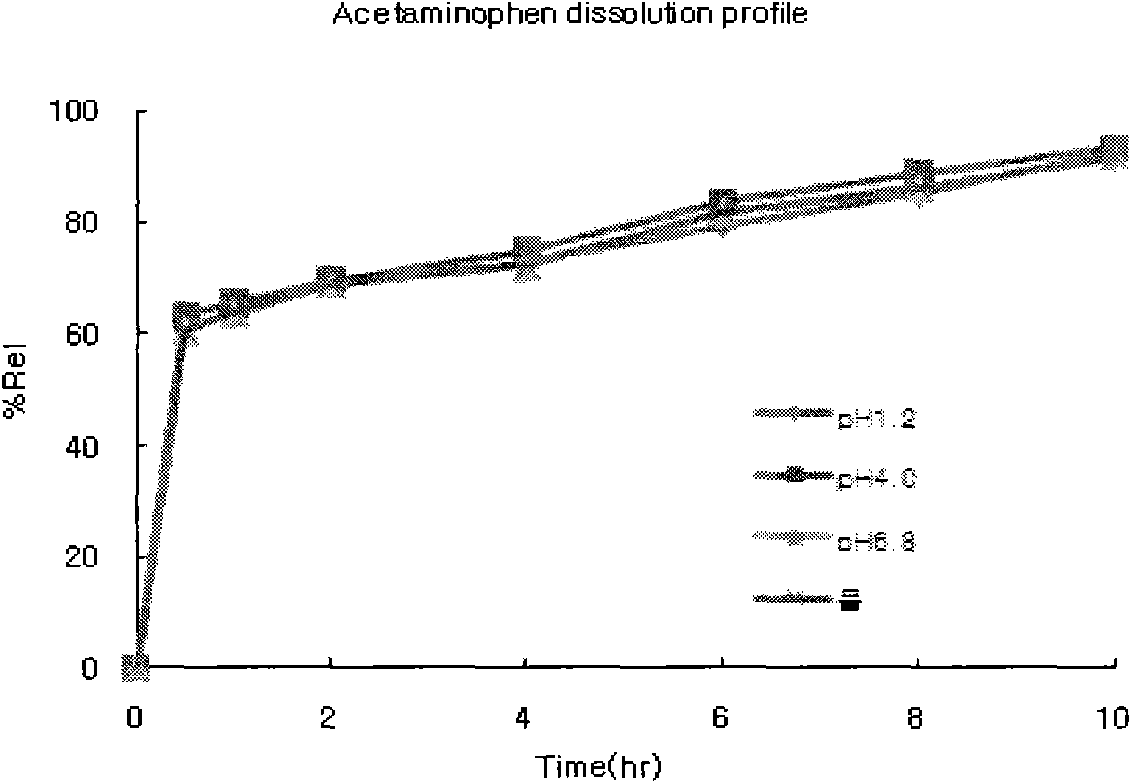

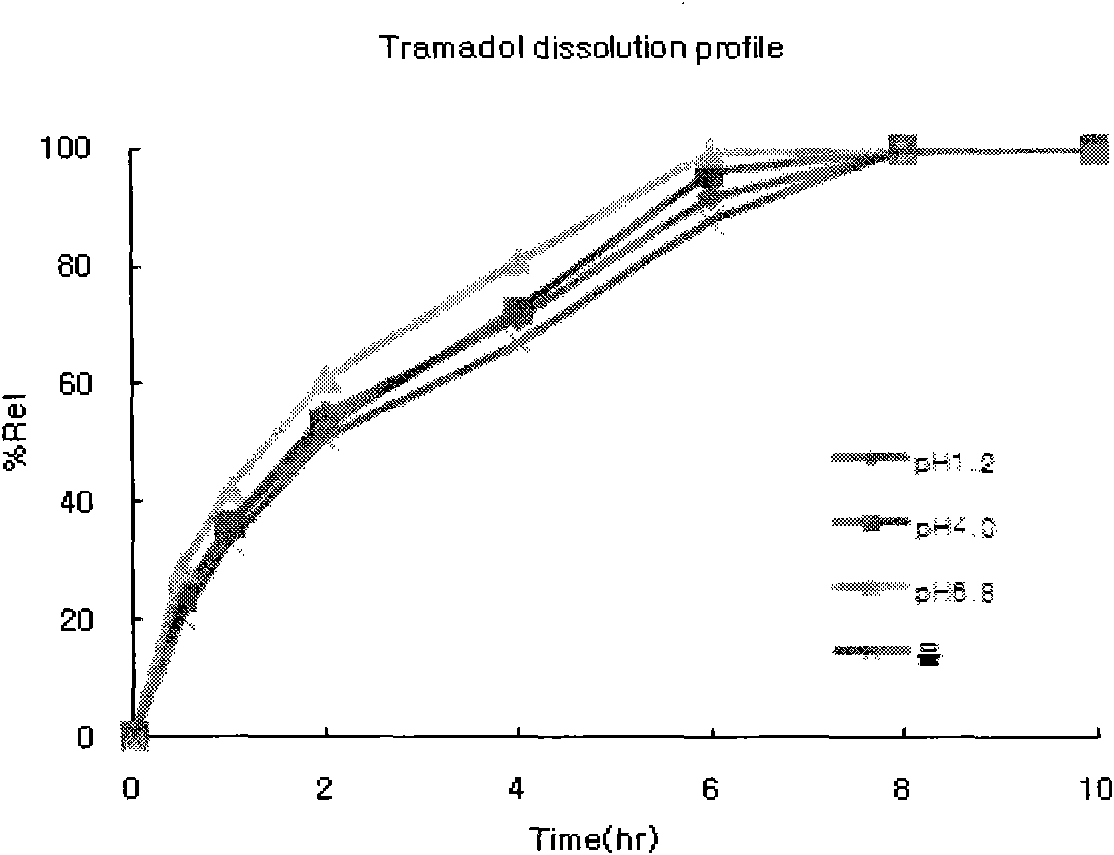

[0030] The prepared tablets were subjected to a dissolution test under the following conditions:

[0031] - Dissolution test method: Stirring method

[0032] - Eluate: .pH1.2 (900mL) ...

Embodiment 4~6

[0041] Unit: mg

[0042] raw material

Example 1

Example 2

Example 3

325.0

325.0

325.0

Silica Dispersion

3.0

3.0

3.0

15.0

15.0

15.0

Polyvinylpyrrolidone (PVP K-25)

64.5

25.0

12.0

Low-substituted hydroxypropyl cellulose L-HPC

18.1

57.6

70.6

Yellow No. 4

0.4

0.4

0.4

4.0

4.0

4.0

Total

430.0

430.0

430.0

[0043] In order to judge the manufactured tablets, the capping process was observed with the naked eye during the manufacturing process, and the dissolution test under the same conditions as the sustained-release preparation was carried out, and the release was measured when the preparation was disintegrated to more than 80%. Test results: No capping phenomenon was observed in Examples 4 and 5, but ca...

Embodiment 7~9

[0048] :mg

[0049] raw material

[0050]Test results In Examples 7 to 9, there is no decapping phenomenon, and the disintegration time of Example 9 using cross-linked polyvinylpyrrolidone is 8 minutes, which is the fastest.

[0051]

[0052] Polyvinylpyrrolidone was cross-linked using a disintegrant, and its productivity and disintegration time were evaluated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com