Method for preparing graphene by reduction of sulfur-contained compound

A technology of graphene and compounds, which is applied in the field of graphene products prepared by chemical reduction method, can solve the problems of difficulty in obtaining high-quality graphene, low conductivity of graphene, and low conductivity of graphene, and achieve a green and efficient preparation method. The preparation is safe and simple, and the effect of high C/O ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 50 mg of graphene oxide to 50 ml of deionized water, and ultrasonicate it in an ultrasonic bath for 5 minutes to make it uniformly disperse into a yellow liquid, then add 1.35 or 2.7 mmol of reducing agent NaHSO 3 After uniform dispersion, the temperature was raised to 95°C, and the reaction was maintained for 3 hours under stirring. After the reaction was completed, it was lowered to room temperature and filtered with suction to obtain a black filter cake, which was washed 4 times with 50 ml of water, and then freeze-dried to obtain graphene powder.

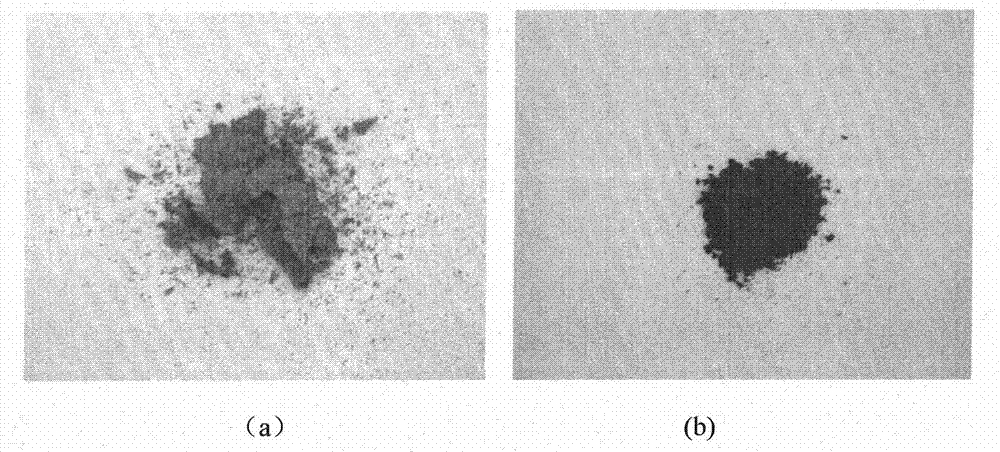

[0028] figure 1 The photos of graphene oxide (a) and reduced graphene (b) are given. It can be seen that the obtained graphene is a black powder. Elemental analysis shows that the C / O ratio of graphene obtained is 7.89, and the degree of reduction is high. . It can also be seen that the method can realize batch preparation of graphene.

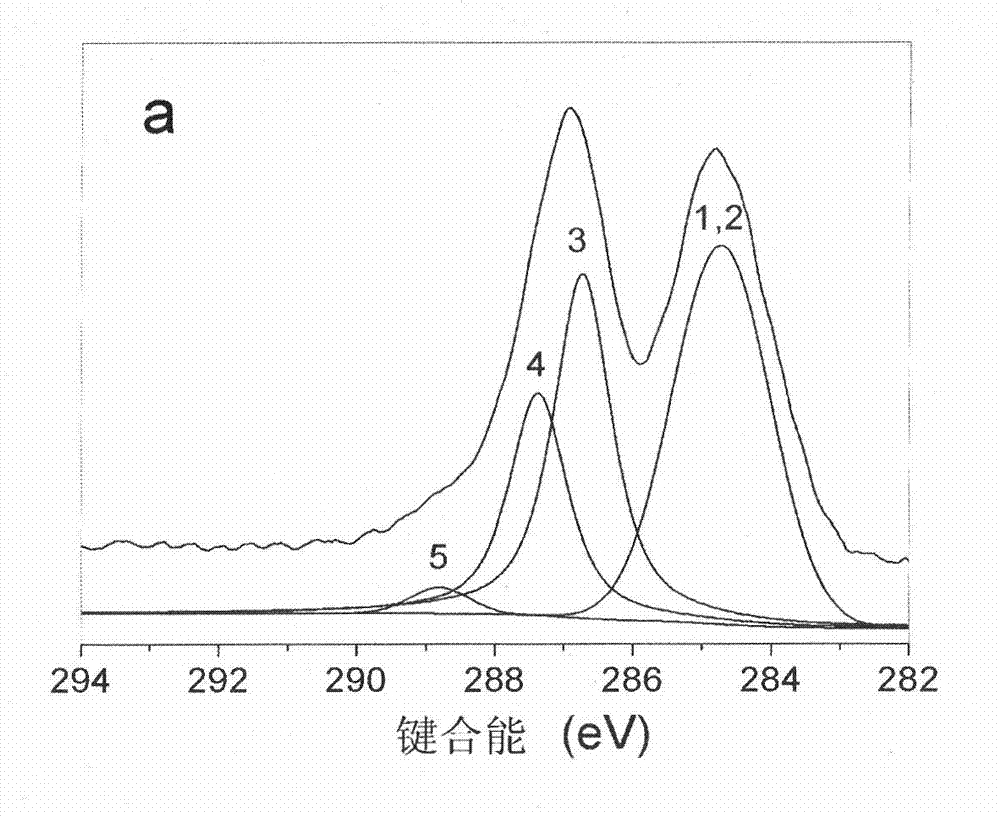

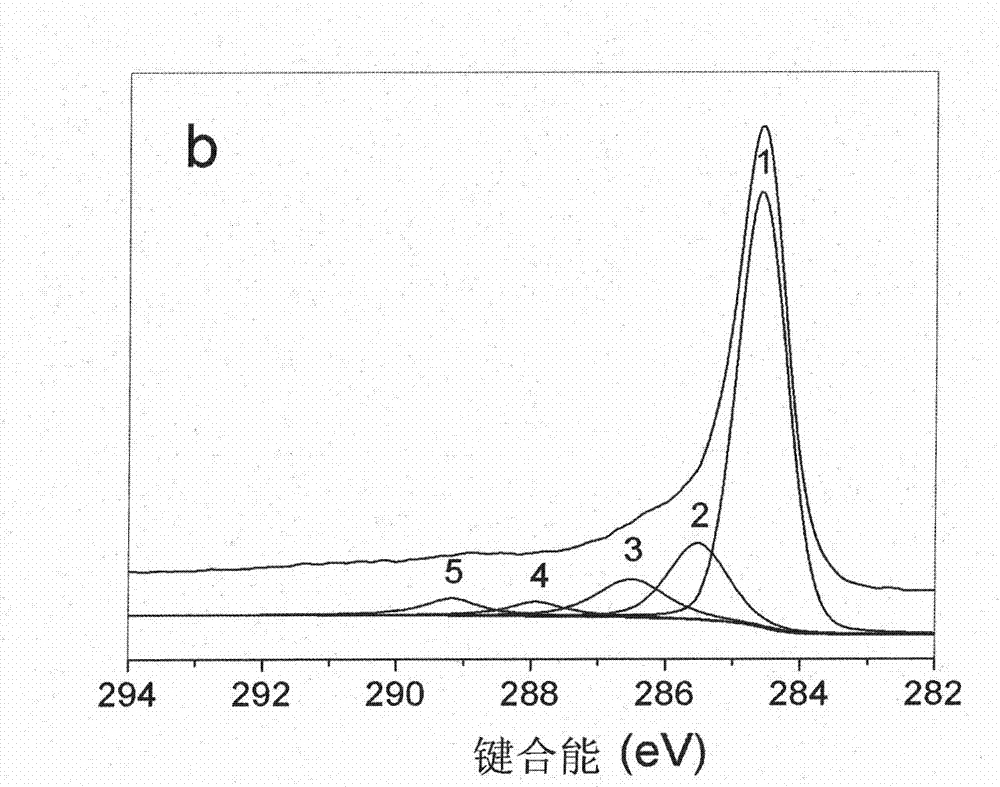

[0029] figure 2 It is the C1s collection of graphene (CRG) obtained in the p...

Embodiment 2

[0036] In this example, 50 mg of graphene oxide was added to 50 ml of deionized water, and ultrasonicated in an ultrasonic bath for 5 minutes to uniformly disperse it into a yellow liquid, and then 5.0 mmol of reducing agent Na 2 S·9H 2 O, after uniform dispersion, the temperature was raised to 95°C, and the reaction was maintained for 3 hours under stirring. After the reaction was completed, it was lowered to room temperature and filtered with suction to obtain a black filter cake, which was washed 4 times with 50 ml of water, and then freeze-dried to obtain graphene powder.

Embodiment 3

[0038] In this example, 50 mg of graphene oxide was added to 50 ml of deionized water, and ultrasonicated in an ultrasonic bath for 5 minutes to uniformly disperse it into a yellow liquid, and then 5.0 mmol of reducing agent Na 2 S 2 o 3 After uniform dispersion, the temperature was raised to 95°C, and the reaction was maintained for 3 hours under stirring. After the reaction was completed, it was lowered to room temperature and filtered with suction to obtain a black filter cake, which was washed 4 times with 50 ml of water, and then freeze-dried to obtain graphene powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com